How to Optimize Artificial Lift Systems

Artificial lift systems are significant in the oil and gas sector, especially in wells that are old or have low-pressure reservoirs in which the natural energy source is not enough to propel hydrocarbons towards the surface. The ability to optimize these systems is crucial to increasing production, prolonging the life of wells, and decreasing the operational cost. This article outlines the effective strategies and technologies to optimize artificial lifting systems.

Common Artificial Lift Methods

Here’s a table that outlines the most common artificial lift techniques, along with the key characteristics of each:

| Artificial Lift Method | Ideal Application | Advantages | Limitations |

| Rod Pump (Beam Pump) | Medium- to shallow-depth wells, with moderate to low production rates | Reliable, simple, and easy to maintain | Limits on depth and volume Limitation in depth and volume capacity; mechanical wear |

| Electric Submersible Pump (ESP) | Deep wells that produce high rates | Capacity to handle large volumes, suitable for deep wells | Gas interference; high cost at first |

| Gas Lift | Wells with a high ratio of gas to oil or unstable production | Flexible Handles higher GOR, with less mechanical wear | Continuous gas supply is required Lower efficiency at low pressure. |

| Progressing Cavity Pump (PCP) | Fluids that are viscous or sand-laden and sand-laden fluids; moderate to low flow rates | It is tolerant of viscous fluids and solids and low maintenance | Application limited to depth and sensitive to temperatures above a certain point. |

| Hydraulic Pump | Wells when other methods are not practical or used for offshore usage | Flexible to various well conditions and suitable for wells with deviated lines | More complex surface components; less efficient |

Key Strategies for Optimizing Artificial Lift Systems

1. Matching Lift Type to Well Conditions

A very critical first decision in the process of optimizing is choosing a lift method that matches the specific features of the well. For instance, electronic submersible pumps (ESPs) are perfect for deep wells that have high volume rod pumps perform ideally in wells that are shallow wells that have less production. Gas lift is typically best suited for wells that have high gas-to-oil ratios. The progressive cavities pumps (PCPs) are efficient in dealing with abrasive or viscous fluids. Choosing the correct method from the beginning creates an excellent foundation for optimization.

2. Leveraging Real-Time Data and Automation

Artificial lift optimization in the modern age is based on data. Monitoring systems that are real-time, such as SCADA (Supervisory Control and Data Acquisition), enable operators to monitor the most important performance indicators, such as the pressure of intake to the pump and the rate of flow, vibration temperatures, as well as the consumption of energy. By continuously analyzing these indicators, operators can spot any deviations from the normal operating procedure and adjust their systems prior to minor issues becoming serious issues.

Automation plays an essential role in responding to data. Variable-speed drives (VSDs), for instance they can adjust the pump speed in real time to ensure the optimal flow rate and cut down on energy consumption. When they are integrated into artificial intelligence-powered systems, such adjustments become more predictive than reactive, further improving the efficiency of the system.

3. Embracing Predictive Maintenance

Traditional maintenance procedures are typically reactive, meaning they are activated only when equipment malfunctions. This could result in expensive downtime and damage. Predictive maintenance, based on algorithms and data from the past, lets operators anticipate possible problems based on patterns and abnormalities within operational information. By intervening earlier, businesses can prolong the life of equipment as well as reduce repair costs and increase the efficiency of production.

4. Proper Sizing and Configuration

Even the most efficient lift system could fail in the event that it isn’t properly designed or sized. Large pumps can consume excessive power and cause mechanical strain, while inadequate equipment might be unable to maintain the pace of the volume of fluid produced, which can lead to the backpressure to drop and a decrease in performance. Regular evaluation and monitoring of specifications for equipment against actual information will make sure that lift systems function within the optimal parameters.

5. Integrating Reservoir Management

Artificial lift optimization shouldn’t be done in the absence of other optimization strategies. It has to be integrated with the larger strategy of managing reservoirs. In the case of excessive lifting, for instance could cause issues like gas or water coning, which could affect the performance of the reservoir. A coordinated approach, where the production team, reservoir engineers, and lift specialists collaborate to ensure that the production strategies are symbiotic and long-lasting.

6. Conducting Routine Performance Audits

Audits of performance are mandatory to uncover inefficiencies and maximize opportunities. The audits include looking at the production data, comparing the performance with benchmarks from the past, and analyzing trends that might indicate the emergence of issues. Audits can help operators remain proactive and modify strategies as changes occur in the environment.

7. Investing in Training and Collaboration

In the end, optimization is just as important as technology and people. Making sure that field workers, as well as analysts, engineers, and technicians, are trained in artificial lift technology as well as optimization software is essential. In addition, fostering cross-disciplinary cooperation between the teams of production, reservoir data science, production, and maintenance ensures a comprehensive method of improving performance.

How Simulations are Used for Optimizing Artificial Lift Systems

To maximize the efficiency of oil and gas production, simulation technology has been developed as an effective tool for enhancing artificial lifting systems. These systems, which are essential to keeping flow in wells despite low reservoir pressure, need careful planning, constant monitoring, and regular adjustments. Oil and gas simulations enable engineers to evaluate and improve techniques for artificial lifting in a secure digital environment before deploying these strategies in the field, which ultimately saves time, cuts costs, and enhances the reliability of operations.

- Virtual Prototyping and Design Validation

Simulations are used first during the development and selection phase for artificial lifting systems. Through the input of precise information–such as depth and pressure, temperature, fluid properties, as well as production goals–engineers can simulate the way that different methods of lifting (rod pumps gas lift PCPs, gas lift) can perform. This prototyping process helps to find the best lift technology, and also fine-tune equipment configuration and sizing to ensure that the chosen technology meets expectations for performance without over-designing or under-delivering.

- Predicting System Behavior Under Changing Conditions

They are dynamic and dynamic environments. In time, environmental parameters like the pressure of reservoirs and water cut, as well as gas-to-oil ratios, may change dramatically. Simulations help operators predict how artificial lift systems are likely to react to these changes in parameters. For example, engineers could predict the effects on the efficiency of an ESP as the production of gas increases, or what happens to a rod pump responds to an abrupt increase in the sand content. These insights can be used to make intelligent system adjustments that can avoid mechanical or performance issues.

- Optimizing Operating Parameters

Once the lift system has been installed, simulations assist in fine-tuning operational parameters like pump speed, gas infusion speed, length of stroke, or the cycle frequency. Instead of relying solely on trial-and-error in the field, operators can run scenarios in the simulation system to identify the most efficient setting. This will ensure artificial lift systems work within their maximum performance range, which reduces energy usage and mechanical strain while ensuring constant production rates.

- Troubleshooting and Failure Analysis

If production issues arise, simulations can be extremely helpful in diagnosing. Engineers can replicate the real-world environment digitally to identify issues such as gas lock problems in ESPs and problems with the plunger lift and fluid fallback issues within the rod pump. This accelerates root-cause analysis and allows for the corrective steps with greater precision, and reduces downtime.

- Supporting Digital Twin Applications

Modern oilfields are increasingly dependent on digital twins, which are real-time virtual replicas driven by data that replicate lift systems and physical wells. They integrate sensors and simulation models that continuously mirror the field’s operations. Operators can make use of digital twins to evaluate “what-if” scenarios, assess the effects of changes in parameters or adjustments, and even automate the process of making adjustments using AI-driven suggestions. The ability to simulate in real-time allows continuous optimization of the conditions.

- Economic and Risk Assessment

Simulations also serve as a tool for cost-benefit analysis and risk analysis. Through modeling various scenarios for lift, managers are able to examine the trade-offs between capital investment as well as operating costs and anticipated production outcomes. This can help justify the investment decision and reduce the risk of financial loss by ensuring that any modification to the artificial lift method will result in an acceptable return.

Emerging Technologies in Optimizing Artificial Lift Systems

As the oil and gas operations shift towards more intelligent, information-driven processes, artificial lift systems are undergoing technological transformation. Many wells are producing in increasingly complicated conditions, such as deep reservoirs, greater gas content, and changing flow rates, and traditional lift systems struggle to ensure maximum efficiency. To tackle these issues, emerging new technologies are changing the way artificial lifting systems are designed, monitored, and improved.

- Autonomous Artificial Lift Systems

A new generation of self-contained lift systems is on the horizon that is driven by AI robotics, robotics, along with remote connectivity. These systems can monitor themselves, identifying issues and making adjustments in real-time. For example, the autonomous electric submersible pumps are able to control motor speed and fluid intake in response to fluctuations in flow, thus reducing time between maintenance and maximising run times without needing constant monitoring.

- Advanced Materials and Additive Manufacturing

The durability and performance in artificial lifting systems are further enhanced by the use of development of advanced materials and additive production (3D printing). The latest composite materials provide more resistance to corrosion erosion as well as high temperature, thus extending the lifespan of parts like tubing and pump shafts. Additive manufacturing allows the development of customized intricate parts that require more precision and speedier processing times, increasing the design flexibility while reducing the supply chain’s constraints.

- Cloud-Based Analytics and Remote Operations

As we move to cloud-based platforms, artificial lift optimization can no longer be confined by local restrictions. Engineers have access to analytics dashboards, performance dashboards, and real-time alerts from any location, which allows central control of multiple wells in various regions. This allows for more efficient decision-making and collaboration, particularly for offshore or remote operations.

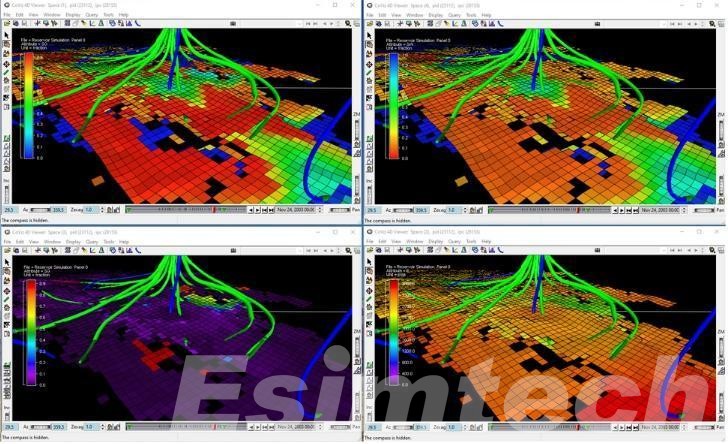

- Integration with Reservoir Simulation Software

Optimization is becoming more holistic since artificial lift systems are becoming more connected to reservoir models. This enables engineers to connect the behavior of subsurface operations to surface operations, which allows for more accurate decisions regarding the flow rate, management of pressure, and methods to reduce depletion. The interaction between surface lift technologies and reservoir simulations ensures artificial lift not only ensures the production of the plant, but also increases the overall recovery.

Final Thoughts

Optimizing artificial lift systems is a multi-dimensional job that requires engineering design analysis, data analytics, monitoring in real-time, and an esoteric alignment with the reservoir conditions. Through the use of smart technologies, predictive maintenance, and specific lift techniques, operators can greatly increase the efficiency of production, cut expenses,, and extend the lifespan of oil and gas wells using optimized artificial lift methods.