The Role of Artificial Lift in Extending Well Life in Depleted Reservoirs

As oil and gas reservoirs age, their natural pressure drops making extraction of remaining hydrocarbons increasingly challenging. Artificial lift systems play a pivotal role in maintaining production while prolonging well life for depleted wells – in this article we investigate their operation, why it’s essential for depleted reservoirs, as well as various systems used by industry.

What Is Artificial Lift in Oil and Gas?

Artificial lift refers to any method employed to enhance or maintain oil or gas flows from wells when natural pressure alone no longer has the strength necessary for pushing them upwards to the surface. It plays an integral part in increasing production rates while continuing well operations effectively even as natural driving mechanisms like water or gas pressure decrease, often when reservoir pressure declines and natural flow is no longer viable. Artificial lift methods may be implemented when this situation arises.

Artificial lift serves three primary goals for wells: minimize downtime, optimize production and ensure economic viability over their lifecycle. By injecting external energy, artificial lift systems can overcome declining well pressure to lift oil or gas to the surface for continued production and extend productive lifespan of each well.

Why Depleted Reservoirs Need Artificial Lift

As a reservoir depletes, the energy that drives fluid to the surface gradually decreases. Over time, the pressure within the reservoir is no longer sufficient to lift the hydrocarbons to the surface, leading to reduced production rates. In these cases, artificial lift plays a critical role in continuing to extract hydrocarbons and maintaining the well’s productivity.

Depleted reservoirs, especially those that have been in production for several years, often face challenges such as:

- Decreasing Pressure: As reservoir pressure decreases, oil or gas becomes harder to flow naturally through the wells.

- Lower Flow Rates: Depletion leads to decreased flow rates, which threaten profitability if left unaddressed.

- Viscosity Variations: Over time, oil viscosity tends to increase gradually, making it increasingly difficult for fluids to reach the surface without assistance from outside sources.

Artificial lift systems can help to combat these challenges by providing the necessary energy to bring fluids to the surface efficiently. This extends the operational life of the well, reduces the need for new drilling, and ultimately improves the economics of a depleted reservoir.

Common Types of Artificial Lift Systems

Several artificial lift systems are commonly used in oil and gas production, each with unique features suited for different well conditions and reservoir types. Below are some of the most widely adopted systems:

Electric Submersible Pumps

Electric submersible pumps (ESPs) are among the most cost-effective artificial lift systems and are widely utilized by oil wells with moderate to high production rates. Comprised of a pump, motor, cable system that submerges into the well and runs off electricity as its source, electric submersible pumps (ESPs) have long been known for lifting large volumes of fluid out of deep wells; particularly effective where natural pressure has significantly dropped off.

Pumps of this size are well suited to low to medium volume wells and are frequently employed offshore operations or deep onshore wells. Extra Super Pumps (ESPs) should be employed if an oil well’s production rate starts decreasing but still has significant oil recovery potential.

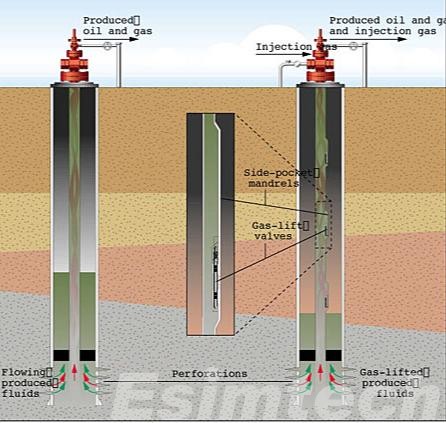

Gas Lift

Gas lift is another popular method of artificial lift, particularly effective for wells with high gas-to-liquid ratios. It involves injecting gas (typically nitrogen or natural gas) into the well to reduce the density of the fluids, making it easier for the hydrocarbons to flow to the surface.

This system is highly versatile and can be applied in both vertical and deviated wells. Gas lift is often used when the well produces a combination of oil and gas, and natural gas is available for injection. This method works best in wells where the production fluids are too viscous for other lifting methods.

Rod Pumps

Rod pumps (also referred to as beam or sucker rod pumps) are one of the oldest and most widespread artificial lift methods used today, consisting of an artificial surface pumpjack connected to a mechanical rod system which transports oil up the wellbore through its mechanical rod system and into an artificial welljack. They’re particularly beneficial when lifting oil from shallow to mid-depth wells with moderate flow rates.

Rod pumps are well suited to wells with lower gas-to-liquid ratios that have become inactive; their simplicity, reliability, and cost effectiveness make them popular choices in fields where production rates have begun to dwindle over time.

Progressing Cavity Pumps

Progressing cavity pumps (PCPs) are widely utilized in wells containing highly viscous fluids such as heavy oil and are best suited for wells with lower to medium production rates. Their system comprises of an enclosed helical screw inside an enclosed stator which transports fluids between the wellbore and surface locations.

PCPs can provide consistent lifting action that ensures production even after natural flow has decreased significantly in depleted reservoirs, even where viscosity has significantly increased due to lower temperatures or pressure. They offer reliable production when natural flow has diminished substantially.

How Artificial Lift Extends Well Life

As oil and gas reservoirs mature, natural pressure declines, making it increasingly difficult to sustain production. Artificial lift systems play a pivotal role in revitalizing these wells, ensuring continued extraction and maximizing reservoir potential. Here’s how they extend well life:

1. Reduce Declining Reservoir Pressure

As time progresses, natural drives weaken, lessening the energy needed to push fluids towards the surface. Artificial lift serves to counter this loss by providing external energy, thus maintaining or even increasing production rates that would otherwise decrease.

2. Improves Hydrocarbon Recovery

Without artificial lift systems, many wells would be abandoned prematurely and the valuable recoverable reserves left unused. By optimizing flow rates, these systems help extract more oil and gas for recovery purposes, thereby increasing the recovery factor of the reservoir.

3. Adapts to Varying Well Conditions

As wells become older, factors such as increased water cut, gas interference, or sand production can compromise performance and require adjustments such as installing or adjusting artificial lift method, such as ESPs (for high water cut situations or viscous fluids) to keep production constant and steady. Artificial lift methods (like PCPs for viscous fluids). can be deployed or adjusted accordingly so as to remain effective solutions while keeping production consistent and ongoing.

4. Enhancing Economic Viability

Artificial lift can significantly enhance economic viability for operators by prolonging well production at profitable levels, delaying abandonment, and prolonging its economic life, thereby optimizing return on investment while deferring decommissioning costs. This allows operators to maximize return while deferring decommissioning costs as soon as possible.

5. Enabling Secondary and Tertiary Recovery

Artificial lift can facilitate secondary and tertiary recovery strategies used by enhanced oil recovery (EOR), such as water flooding or gas injection. By maintaining flow rates, artificial lift can enhance these EOR methods, further increase recoverable reserves, and thus create additional recoverable reserves.

6. Reduces Well Failures and Downtime

Modern artificial lift systems come with monitoring and automation capabilities, allowing operators to detect issues early and optimize performance. This reduces unexpected failures, minimizes downtime, and prolongs well productivity.

Artificial lift is not just a temporary fix—it’s a long-term strategy for extending well life in depleted reservoirs. By maintaining production, improving recovery, and adapting to evolving well conditions, these systems ensure that mature fields remain profitable for years to come.

Artificial lift technologies play a pivotal role in prolonging the lives of oil and gas wells in depleted reservoirs, particularly through improved fluid flow, lower operating costs, and overall increased recovery rates. Artificial lift can extend production beyond natural reservoir pressure that has depleted, helping wells keep producing efficiently well after natural reservoir pressure has fallen off significantly. As the oil and gas industry faces depleting fields challenges head-on, artificial lift technologies remain crucial tools in optimizing productivity, longevity, and the economics of reservoir management.