Key Technologies Driving Unconventional Oil and Gas Production

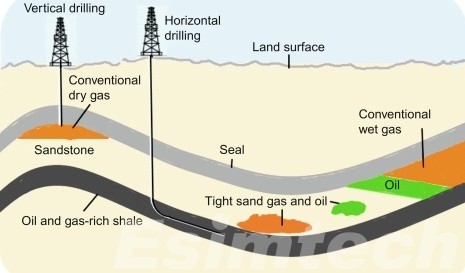

Unconventional oil and gas production is now a key element of the global energy supply that is transforming markets and allowing access to vast hydrocarbon reserves previously considered uneconomic. Contrary to conventional resources that are found in permeable, porous deposits, Unconventional oil and gas like shale gas, crude oil, oil sands and coalbed methane, require advanced extraction methods and specialized technologies. These technologies have played a significant role in unlocking energy from geologically complex settings.

What is Unconventional Oil and Gas

Unconventional oil and gas are hydrocarbon sources that cannot be extracted using conventional drilling techniques because of their nature or the physical condition of the material. They include:

- Shale gas and tight oil: They are found in formations of shale with low permeability, which require hydraulic fracturing and horizontal drilling.

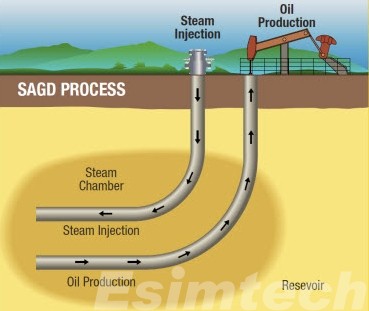

- Oil sands: Mixtures made of clay, sand, water, and bitumen. Typically extracted through the surface or in-situ thermal techniques.

- Coalbed methane (CBM): Methane that is stored within coal seams and released through the lowering pressure of water.

- Gas hydrates: Methane that is trapped in ice-like structures at low temperatures and high pressure, which are typically found in permafrost and deeper ocean sediments.

They were previously thought to be not economically viable or technologically beyond reach, but recent advances have allowed their extraction to become feasible.

Key Extraction Technologies for Unconventional Oil and Gas Production

1. Hydraulic Fracturing (Fracking)

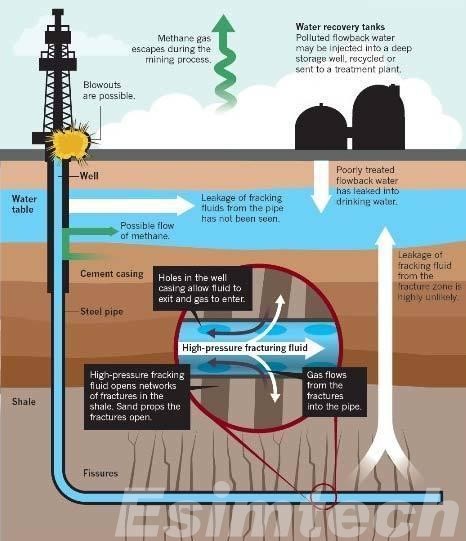

Hydraulic fracturing may be the most important technology to ensure the commercial potential in the field of undiscovered resources. It involves injecting a high-pressure liquid, typically composed of water as well as chemicals, sand, and sand--into rocks with low permeability to create fractures. These fractures allow hydrocarbons to flow more easily into an oil production facility.

Fracking is particularly important in shale gas as well as the development of tight oils throughout North America, converting once-inaccessible zones into massive production hubs. Technology-driven refinements, like multi-stage fracking or zipper fracs, have improved the efficiency of recovery and reduced operational expenses.

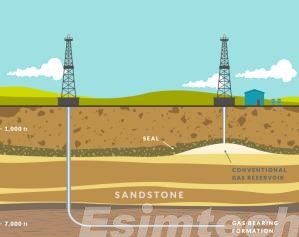

2. Horizontal Drilling

Horizontal drilling complements fracking by maximizing reservoir contact. After drilling vertically to the intended depth, drilling is moved in a horizontal direction through the formation, typically for a distance of hundreds of meters. This technique greatly increases the depth of the well's exposure toward the reservoir and allows more flow of hydrocarbons with smaller surface wells.

Horizontal drilling has revolutionized field development strategies by minimizing surface disturbance while increasing productivity. It is a common procedure in shale plays such as those of the Permian Basin, along with the Marcellus Shale.

3. Advanced Seismic Imaging

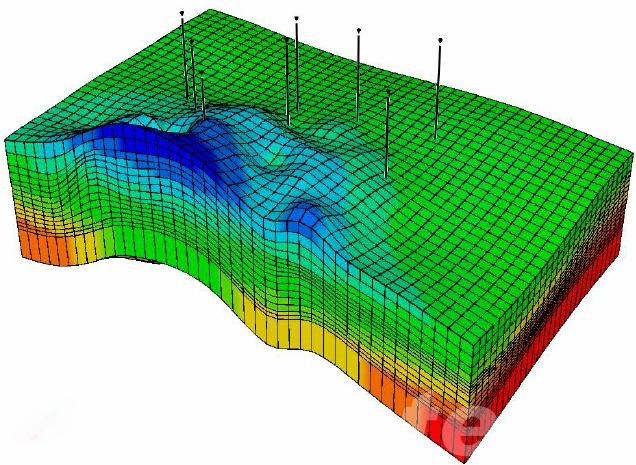

Understanding the complicated geochemistry of reservoirs that are unconventional reservoirs is essential to ensuring the development of the reservoir is successful. Three-dimensional and four-dimensional seismic imaging technology provides precise subsurface maps that guide drilling decisions as well as improve hydraulic fracturing design.

The tools for seismic analysis help operators visualise fractures, faults, and rock characteristics, thereby reducing the risks of exploration and improving the management of reservoirs. Time-lapse (4D) seismic images allow monitoring of changes to reservoirs in production, which allows better informed decision-making.

4. Microseismic Monitoring

During fracking, the use of real-time microseismic monitoring is employed to monitor fracture growth and underground behavior. Through the use of geophones within close to wells, engineers are able to observe small seismic disturbances caused by the process of fracturing.

This technology lets operators determine the effectiveness of every phase of stimulation and then adjust treatments in real-time and limit the risk of unintentional fracture propagation and seismicity.

5. Pad Drilling and Simultaneous Operations

Pad drilling involves drilling several horizontal wells from one site, also known as a "pad." This reduces the disturbance of land, operational expenses, and environmental footprint. When combined with simultaneous production (SIMOPS)--where the drilling process, its completion, and production take place simultaneously on the same pad--operators can increase efficiency and speed up the time until first gas or oil.

This approach is commonly used in large-scale shale development projects to increase output and improve logistics.

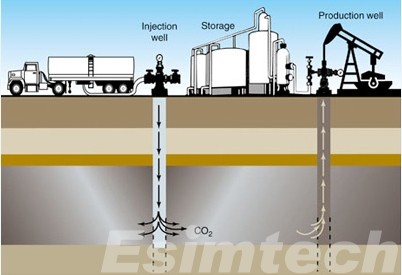

6. Enhanced Oil Recovery (EOR) in Tight Reservoirs

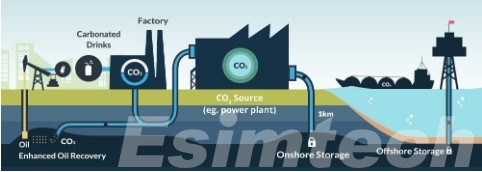

While traditional enhanced oil recovery techniques such as CO2 flooding and steam injection are well-established, adjusting the techniques to unconventional reservoirs brings new issues. Innovative techniques like gas huff-and-puff and low-salinity water injection or nanofluid-based EOR are being investigated to enhance recovery in tight formations.

In certain fields in certain fields, the CO2-derived EOR is also being utilized to capture carbon and enhance the recovery of hydrocarbons, thereby contributing to sustainability for the environment.

7. Real-Time Data Analytics and Automation

Digital technology plays a growing, crucial role in production that is not conventional. With sensors and remote monitors as well as data analysis, workers are able to keep track of temperature, pressure, and flow rates in real-time. Computer-aided learning techniques are utilized to anticipate failures of equipment as well as optimize fracking designs and increase the spacing of wells.

Automation decreases the requirement to have personnel on-site and increases security, particularly in harsh or remote environments. It also facilitates more reliable and precise operations across multiple platforms.

8. Drilling Fluids and Proppant Innovations

The efficiency of hydraulic fracturing is heavily dependent on the proppants and drilling fluids. The chemistry of Innovative drilling fluids that reduce environmental impacts, like biodegradable or water-free fracking fluids, is beginning to gain momentum.

In parallel, proppants, which are materials such as sand or ceramics that are used to seal fractures, are being developed to provide greater strength, less weight, and improved efficiency in transport. The latest developments in proppant coating technology will also increase the efficiency and speed of flow.

How Simulation Technologies are Used for Unconventional Oil and Gas Production

To deal with the geological complexity and technical uncertainty that is inherent in unconventional production of oil and gas, Simulation technologies have become indispensable at all stages in development from subsurface characterisation through field operation.

- Subsurface Modeling and Reservoir Simulation

One of the most important applications for simulations in the field of unconventional oil and gas production is in the simulation of complicated subsurface environments. Unconventional reservoirs tend to be heterogeneous and show intricate fluid-rock interactions, rendering traditional methods of analysis inadequate. Reservoir simulation platforms enable geoscientists and engineers to develop model reservoirs that are dynamic and incorporate geophysical, geological, and petrophysical information. They help in predicting the way that hydrocarbons behave over time, providing insight into the flow of fluids and pressure change, as well as the interactions between rock matrices and fractures. In turn, operators are able to make better decisions regarding the placement of well spacing, spacing, as well as the design of completion, greatly improving the efficiency of recovery.

- Optimizing Hydraulic Fracturing Operations

Hydraulic fracturing plays a crucial role in unlocking hydrocarbons trapped in hard formations. Simulation is a key element in the process of optimization. Fracture modeling software allows for the estimation of the way that fractures begin and spread throughout the reservoir rock when they are stimulated. The fracturing simulations take into account factors like pressure in the rock as well as fluid viscosity and proppant distribution. Through analyzing these variables before the actual field operation, engineers can modify fracture designs according to specific characteristics of reservoirs. This helps reduce the chance of interference from fractures, minimizes environmental impact, and boosts the production of hydrocarbons. Furthermore, data collected in real-time from sensors can be integrated into simulation models to adjust fracture behavior dynamically, providing the development of adaptive strategies for fracking.

- Improving Drilling Efficiency and Safety

Exploring unconventional wells, which are often long and horizontal, requires cautious planning and implementation. Drilling and well control simulation systems help in designing optimal well trajectories while making sure to avoid dangers such as unstable formations or areas of pressure. Virtual drilling environments permit engineers to identify issues prior to their arising, for instance, excessive drag, torque, and mechanical wear. These knowledge-based insights are especially valuable for areas that have complex geology or with limited historical information. Furthermore, simulation-based training courses equip rig personnel to deal with unpredictable scenarios, which improves the safety of operations and efficiency on the job.

- Forecasting Production and Managing Field Performance

When production starts, the simulation process continues to play a crucial role in determining output and managing it. Wells that are not conventional typically have an initial rapid production, which is then followed by a dramatic decrease, which makes it essential to forecast performance accurately. Oil and gas production simulation models that include decline curve analysis as well as rate-transient analysis aid operators in understanding the patterns of depletion in reservoirs and evaluating the efficiency of stimulation techniques. They also aid in making the decision-making process for the deployment of artificial lifting, refracturing, or drilling for infill. By simulating various scenarios, companies can decide which investments are the most appropriate in capital and develop longer-term strategies for production.

- Supporting Infrastructure and Facility Planning

The discovery of unconventional resources is typically found in remote areas with no infrastructure. Simulation technologies aid in the development of pipelines, surface facilities, and processing systems by modelling the movement of gas, oil, and water produced. Simulations enable engineers to test various operating conditions and configurations, virtually making sure that the system is efficient and cost-effective. They also allow for scalability. Simulations, for instance, can detect potential bottlenecks or safety concerns within pipeline networks, which can guide the design of a robust midstream infrastructure.

- Promoting Environmental Responsibility and Compliance

Environmental stewardship is an essential element of unconventional oil and gas activities, and simulation technology helps operators comply with increasingly stringent regulations. Emissions models predict the release of methane as well as other greenhouse gases in the course of production, which allows companies to develop mitigation strategies. Simulations of water management guide the source, recycling, and disposal of water utilized in hydraulic fracturing. They help to limit freshwater consumption and reduce the chance of contamination. Risk simulations also assess the possibility of blowouts and spills on the surface or induced seismicity, helping to manage risk proactively and comply with regulatory requirements.

Challenges in Unconventional Oil and Gas Production

| Challenge | Description | Implications |

| Low Permeability Reservoirs | Unconventional reservoirs usually have extremely compact rock formations. | Needs more sophisticated stimulation (e.g., hydraulic fracture) and requires a larger investment. |

| High Decline Rates | Production decreases sharply following the initial flow. | Requires frequent well intervention or new drilling to maintain production. |

| Complex Geology | Heterogeneous formations can complicate modelling reservoirs as well as positioning. | Exploration risks are increased and require advanced seismic and simulation equipment. |

| Water Usage and Management | Fracturing uses up large amounts of water, especially in areas of extreme drought. | Environmental and regulatory issues are raised and require finding solutions for water reuse. |

| Surface Footprint and Land Access | Drilling pads that are extensive and complex could disrupt ecosystems or communities. | Causes social resentment that can lead to legal obstacles, social resistance, and an increase in the complexity of permitting. |

| Induced Seismicity | Hydraulic fracture and disposal wells could cause small earthquakes. | This could result in regulatory restrictions and even a stoppage of operations. |

| Economic Viability | The cost of capital and operations is high are highly sensitive to the price of gas and oil. | Risks project profitability, particularly during market downturns. |

| Regulatory and ESG Pressures | Investors and government officials demand greater safety and environmental standards. | Encourages the adoption of greener technologies in addition to more open reporting. |

| Infrastructure Limitations | The remote basins usually lack pipelines or processing facilities. | Development is delayed and can increase logistical costs and complexity. |

| Technological Integration | Needs seamless coordination between digital equipment, tools as well and data management systems. | A lack of integration could decrease effectiveness and lead to delays in optimization. |

The Technical Future Outlook in Unconventional Oil and Gas Production

Although the first breakthroughs in hydraulic fracturing and horizontal drilling laid the groundwork and the technological future of this field lies in the ever-changing development of mechanical, digital, and environmental technologies, which promise to improve efficiency, decrease costs, and address environmental concerns.

- Next-Generation Drilling and Completion Technologies

The latest innovations in drilling will improve wellbore accuracy and decrease the amount of time wasted. Techniques like:

- Rotary steerable systems that have real-time telemetry

- Drill bit optimization with predictive analytics, as well as

- Automated rig systems

are expected to become standard.

On the other hand, Smart completion systems that include fiber-optic sensor technology, live monitoring of pressure as well as flow-control devices, will enable the control of zones and boost the efficiency of production throughout the life of the well.

- Waterless and Environmentally Friendly Fracturing

Water usage and disposal remain important environmental concerns when it comes to hydraulic fracturing. Future developments will focus more on techniques for waterless fracturing that include:

- Supercritical CO2 fracture,

- Liquified petroleum gas (LPG) is a liquid that can be used for fracturing and

- Stimulation with plasma pulses.

These options do not just reduce the need for freshwater but also decrease the use of chemicals and their footprint on the surface in line with ESG (environmental, social, and corporate governance) commitments.

- Integration of AI and Automation

The complete digitization of oilfields that are not conventional is in progress. AI, Machine learning, and AI are being utilized to:

- Perform well in prediction,

- It is possible to detect early failures of equipment,

- Automate the stage optimization of fracking

- Support real-time production decisions.

Remote operations centers, as well as robots for wellsite inspections, will be more widespread, which will reduce HSE dangers and costs for operations.

- Carbon Management and Emissions Reduction

As efforts to reduce carbon emissions increase, the alternative industry is investing heavily in Carbon Capture Utilization and Storage (CCUS). Technology is being designed to:

- Capture CO2 in the production process and then inject it back into depleted reservoirs.

- Monitoring leaks of methane with drones, infrared sensors and drones and

- Reduce flaring via the power generation on site and gas reinjection.

These technologies are crucial to keeping a license for society to function and in line with the global climate goals.

- Modular and Scalable Infrastructure

To cut costs and reduce environmental impact, the next unconventional technologies will rely on modular processing units and portable LNG compression stations, and pads with small footprints. These solutions are scalable and allow for quick deployment even in the most remote regions, and reduce the need for infrastructure.

- Circular Resource Management

There is an increasing focus on closed-loop systems that reuse water that is produced, collect heat from waste, and recycle drilling tools. Digital twins and life-cycle analysis tools can assist operators in reducing the use of resources and greenhouse gases from the planning of wells to abandonment.

Summary

The advancements of unconventional oil and gas production are dependent on constant innovation in exploration, drilling, completion, and monitoring techniques. From hydraulic fracturing to real-time analysis, every technology is crucial to unlocking the potential of these reservoirs. As the need for more sustainable, cleaner energy rises, future advancements in this field will focus on increasing the rate of recovery while minimizing environmental impact in unconventional oil and gas.