Reservoir Simulation for Effective Enhanced Oil Recovery (EOR) Planning

Enhanced Oil Recovery (EOR) is a crucial stage in the lifecycle of oil fields. It is aimed to maximize the extraction of hydrocarbons when primary and secondary recovery techniques decrease in effectiveness. In the array of tools that reservoir engineers can use, reservoir simulation has become an essential tool for designing, optimizing, and implementing EOR strategies. With its detailed analysis of the behavior of reservoirs, simulation can help make the use of data to make better decisions that improve efficiency and enhance recovery rates.

The Role of Reservoir Simulation in Enhanced Oil Recovery

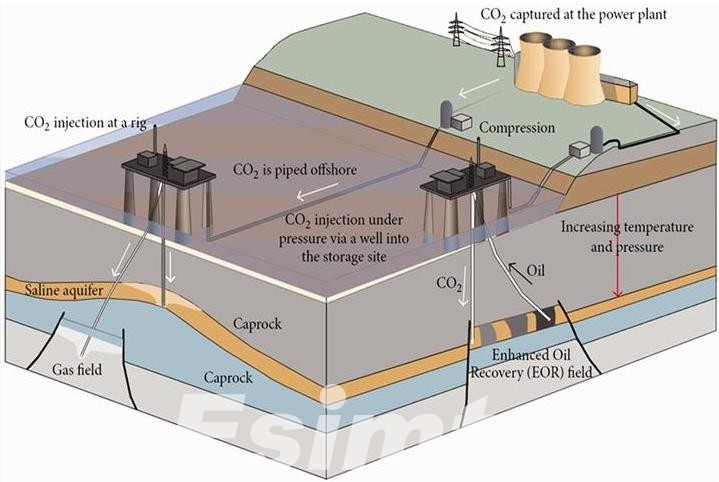

Reservoir simulation entails the use of mathematically sophisticated models to simulate the physical processes that occur within underground reservoirs. These models take into account the flow of fluids, heat transfer and pressure fluctuations, as well as the interactions between rocks and fluids. In the EOR context, simulation is used to predict how different EOR simulation, engineers are able to determine how various EOR methods, such as chemical flooding, gas injection or thermal techniques, will work in a variety of operational and geochemical conditions.

By simulating a range of scenarios, engineers are able to determine how the injected materials will flow across the reservoir and interact already existing petroleum, as well as affect the efficiency of recovery. This kind of predictive power allows for better planning, lower risks, and enhanced decision-making.

Key Benefits of Using Reservoir Simulation for EOR Planning

- Informed Selection of EOR Methods

Each reservoir is unique with respect to its fluid properties, geology and operational limitations. Reservoir simulation offers a controlled setting to evaluate different EOR methods like the CO2 flood, injection of polymers and steam-assisted gravity drain (SAGD). Simulating the response of the reservoir to different methods engineers can pinpoint the most effective and efficient method. This results in more confident decision-making and lessens the risk of settling for strategies that aren't optimal.

- Enhanced Recovery Forecasting

One of the major benefits of simulation is its ability to forecast the oil recovery rate under various operational scenarios. Simulations produce predictive models that show how the reservoir's pressure and saturation rates change in time. Forecasts can help operators determine the amount of oil that can be recuperated, at what speed and at what price, essential information needed for long-term planning and investment choices.

- Optimization of Well Placement and Injection Design

Reservoir simulation assists in determining the most optimal location of production and injection wells. It also allows tuning of rate of injection, the pressure scheduling and patterns in order to maximize the efficiency of sweeps. By reducing bypassed oils and increasing the displacement of fluid simulation aids in the design of cost-effective, high-performance recovery processes.

4. Risk Reduction Through Scenario Testing

Prior to implementing costly operation in the field, simulation lets operators to evaluate a wide variety scenarios "what-if" scenarios virtually. This includes variations in the fluid's properties and fault behavior, as well as risk of breakthrough, and rock integrity. The ability to identify issues using a virtual model decreases uncertainties and increases the risk management in field applications.

5. Improved Economic Planning

Economic feasibility is the most important aspect for the entire EOR project. When you combine the results of a technical simulation together with cost-based modeling, EOR operators can determine the possible returns on investments (ROI) and break-even point and long-term profits. Simulation ensures that resources are efficiently allocated and costly mistakes are prevented.

6. Real-Time Monitoring and Adaptive Optimization

Advanced oil and gas reservoir simulators are able to incorporate real-time information from sensors and production logs. This allows for the continuous updating of reservoir models as well as the ability to adjust the monitoring in EOR operations. Real-time feedback increases flexibility of operations and guarantees that adjustments can be swiftly made in response to changes in reservoir conditions.

- Stronger Stakeholder and Regulatory Communication

Reservoir simulation models are transparent visual representations of the projected reservoir behavior. This allows you to convey complicated technical concepts to regulators, stakeholders as well as investors. Results from simulations can serve to justify the use of project plans, safety measures and environmental impact studies.

Key Steps in Using Reservoir Simulation for Enhanced Oil Recovery Planning

1. Data Collection and Integration

The foundation of a accurate reservoir simulation begins by acquiring comprehensive data. This includes:

- Geological information: structural maps, porosity, permeability, lithology.

- Petrophysical data: such as saturation profiles analysis of cores Well logs.

- Fluid properties: Viscosity, PVT data and compositional analysis.

- Production history: pressures, rates and volumes.

All this data needs to be combined into a unified dataset to construct an exact model of the reservoir.

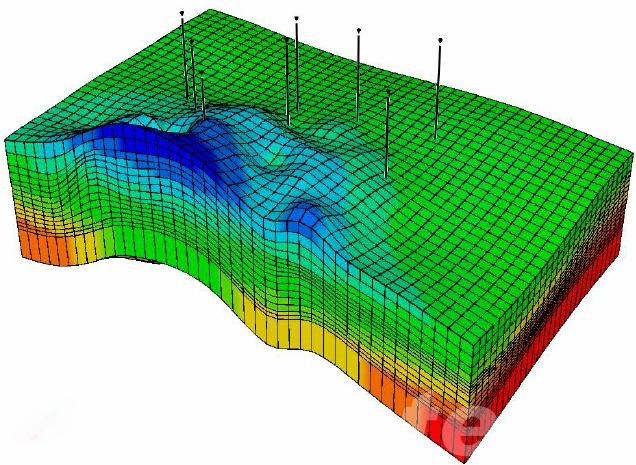

2. Building the Static Geological Model

A static model depicts the reservoir's properties and structure with no time dependence. This can include:

- 3D grids created to depict spatial distribution.

- Define zones, layers, fractures and heterogeneities.

- The assignment of the properties of fluids and rocks to each cell.

This model provides the property and geometric framework upon which dynamic behavior can be modelled.

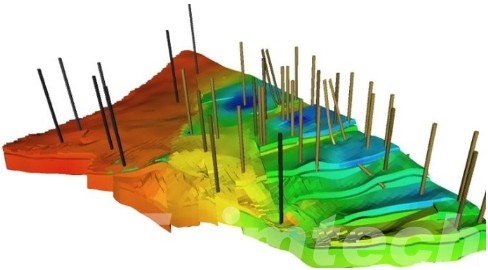

3. Developing the Dynamic Reservoir Model

The dynamic model includes time-based fluctuations that simulate fluid flow as well as pressure fluctuations. This includes:

- The definition of boundary conditions and first reservoir pressures.

- Fluid flow mechanism calibration.

- The process of setting up injection and production scenarios.

This model can be utilized to forecast the reservoir's behavior for natural depletion as well as EOR processes.

4. History Matching

Historical matching refers to the procedure of changing the simulation model in order to ensure that it is able to match the production records from the past. Engineers continuously tune:

- Permeability distributions.

- Permeability curves with relative values.

- Well, performance parameters.

The ability to achieve a perfect match in the past assures the reliability of the model in planning and forecasting the future.

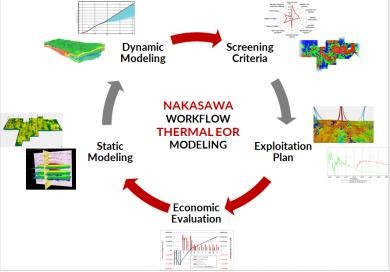

5. EOR Method Evaluation and Screening

Utilizing the model that is matched to history using the history-matched model, a variety of EOR methods are simulated to determine:

- Injectant efficacy (e.g. CO2 polymers, surfactants).

- Efficiency and recovery factors are measured.

- The risk of a breakthrough early or operational difficulties.

Simulation can help narrow down the most economically and technically feasible EOR options.

- Optimization of EOR Parameters

When a method is chosen and a simulation method is chosen, it's used to improve crucial operational parameters, for example:

- Rates of injection and the pressures.

- Well spaced and patterns.

- The timing as well as the sequence EOR phases.

This will ensure maximum recovery, with little operational risk and costs.

7. Forecasting and Economic Analysis

When the optimal plan is put in place, the oil recovery simulators can forecast the production under the chosen EOR scheme. The outputs can be used to:

- Estimating the incremental oil recovery.

- Estimating yields from economic studies (e.g. IRR, IRR, NPV).

- Making development and investment decisions.

8. Ongoing Monitoring and Model Updating

EOR performance must be constantly monitored on the ground, and real-time information should be feed back into the model. This allows:

- Control of operations that can be adapted.

- Re-calibration and model refinement.

- Mid-course adjustments to strategies.

Challenges and Future Solutions in Using Reservoir Simulation for EOR Planning

| Challenge | Description | Future Solutions |

| 1. Data Uncertainty and Incompleteness | Subsurface data is usually insufficient or incorrect, resulting in inaccurate simulation results. | AI-driven data assimilation and machine learning to fill in data and the use of real-time sensor networks. |

| 2. Complex Reservoir Heterogeneity | The variations in the rock properties fluid distribution, rock properties, and geological characteristics make it difficult to perform precise modeling. | High-resolution 3D modeling with improved seismic interpretation and AI-enhanced detection of heterogeneity. |

| 3. Time-Consuming History Matching | Manual history matching is laborious and susceptible to error by humans, causing delays in the calibration process for models. | Automated algorithms for history matching as well as global optimization techniques as well as parallel computer platforms. |

| 4. Limited Understanding of EOR Processes | Certain EOR methods lack a clear understanding of mechanisms within specific structures, which reduces predictive accuracy. | Integration of laboratory-based experimental data as well as improved thermal and chemical modeling methods. |

| 5. High Computational Costs | Large-scale simulations involving complex physics will require a significant amount of computational power and take a long time. | Cloud-based simulation, GPU acceleration, and model simplification, without sacrificing fidelity. |

| 6. Integration of Multiphase and Thermal Effects | Modelling the interactions between liquid, gas and thermal energy creates complexity and may reduce reliability. | The development of unified simulators that manage multi-scale and multi-physics phenomena. |

| 7. Poor Interdisciplinary Collaboration | The lack of interaction between geologists, engineers of reservoirs and data analysts results in unreliable models. | Digital platforms that collaborate with integrated simulation environments as well as digital twins. |

| 8. Regulatory and Environmental Constraints | The majority of simulation tools do not take into account the use of water, emissions, and regulatory impacts in making decisions. | Incorporation of models for environmental impacts as well as sustainable metrics in simulation workflows. |

Final Thoughts

Reservoir simulation is an indispensable element of efficient Enhanced Oil Recovery planning. It helps evaluate, design and optimize complicated recovery processes with precision and confidence. As the oil and gas industry seeks to extend the life of field operations and improve the recovery of hydrocarbons, simulation-driven strategies will be more and more essential to ensure technological success and sustainable economics.