Rigless Well Intervention: Techniques, Applications, and Benefits

Rigless well intervention is an economical and efficient solution for maintaining, repairing, or improving well performance without needing an expensive drilling rig. This approach reduces downtime while cutting operational costs and improving safety, while prolonging oil and gas wells' lives indefinitely.

We examine the key techniques, applications, and benefits associated with rigless well intervention in this article.

What is Rigless Well Intervention?

Rigless well intervention is an innovative technique used to perform maintenance, repair, or upgrade operations on oil and gas wells without the use of traditional drilling rigs. Instead of employing heavy and expensive drilling rig equipment, operators use lighter technologies with greater mobility to access and service the wellbore. This approach enables more efficient well management, particularly in mature fields or offshore environments where space and cost constraints may limit well management efforts.

Rigless interventions can be performed while the well is still producing, which eliminates costly shut-ins and reduces downtime. Common objectives for such interventions include improving production rates, restoring integrity, clearing obstructions, and prolonging its life span. By forgoing full rig setup costs, companies can reduce logistical challenges, lower expenses, and respond quickly to performance issues in wells requiring intervention - thus becoming an indispensable asset in modern oilfield operations.

Techniques Used in Rigless Well Intervention

Rigless well intervention employs a range of specialized techniques that allow operators to perform essential maintenance and optimization tasks without deploying a full-sized drilling rig. These techniques are designed to be efficient, cost-effective, and adaptable to both onshore and offshore environments. Below are the primary methods used in rigless interventions:

Wireline Interventions

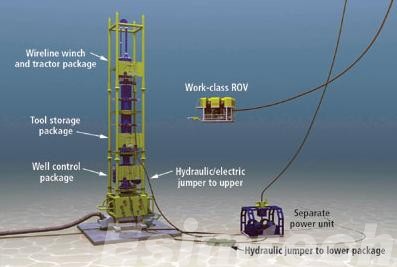

Wireline operations are one of the most cost-effective rigless intervention techniques, using either slickline or electric line (e-line) to deploy tools into wells for interventions such as setting or retrieving plugs, valves, and gauges; while e-line allows more complex operations like logging, perforating, real-time data acquisition. Wireline interventions are quick to mobilize with minimal surface equipment needed - perfect for routine maintenance and diagnostic activities.

Coiled Tubing Interventions

Coiled tubing is a continuous, flexible steel pipe wound on a large reel and injected into the well while under pressure. It allows for extended reach and the ability to circulate fluids, pump treatments, and deploy downhole tools. Coiled tubing is highly effective for tasks like wellbore cleanouts, acidizing, scale removal, nitrogen lifting, and stimulation treatments. Its ability to remain in continuous operation during downhole work makes it a preferred method for complex interventions.

Snubbing Units

Snubbing involves forcing pipe into the wellbore under pressure, enabling live well interventions without killing it. Snubbing units are especially beneficial in high-pressure environments where traditional techniques might present safety or technical challenges; their versatile capabilities make them suitable for tasks as diverse as installing completion equipment, fishing operations and performing remedial works under pressure.

Hydraulic Workover Units (HWUs)

Hydraulic workover units serve as a powerful alternative to rigs for heavy-duty interventions. These units can remove and replace tubing, conduct completions, and handle a variety of downhole repairs. HWUs provide significant lifting capacity and are ideal for wells that require major mechanical work without halting production. Their compact footprint also makes them suitable for offshore platforms and congested sites.

Pumping and Stimulation Services

Rigless interventions often include surface pumping operations to deliver fluids into the well for tasks like acid stimulation, hydraulic fracturing, cement squeezing, and chemical treatments. These services can enhance reservoir connectivity, dissolve formation damage, and boost overall well productivity. Since no rig is needed, these treatments can be executed swiftly with minimal disruption to ongoing production.

Each of these techniques brings a unique advantage to the rigless intervention toolkit, enabling operators to tailor solutions based on the specific well conditions and desired outcomes.

Rigless Well Intervention Applications

Rigless well intervention techniques have become an indispensable asset to the oil and gas industry for solving various operational challenges without needing a full drilling rig. They are particularly beneficial when it comes to maintaining production levels, improving recovery rates, or protecting well integrity across both mature and active wells.

- Production Optimization: Rigless interventions provide an effective means of increasing declining production by performing tasks like scale removal, reperforation, and acid stimulation. Coiled tubing or wireline tools can target trouble spots with precision to restore flow rates without costly rig-based workovers.

- Well Maintenance & Repair: Operators use snubbing units and hydraulic workover systems to replace damaged tubing, repair leaks or install plugs without disrupting pressure in the well. This approach reduces formation damage while eliminating well-kill operations.

- Diagnostics & Monitoring: Wireline logging and downhole cameras offer real-time insights into well conditions, enabling engineers to assess reservoir performance, detect sand ingress or identify casing corrosion - insights which guide intervention strategies moving forward.

- Decommissioning & Abandonment: Rigless plug-and-abandonment methods make plugging and abandonment (P&A) operations faster by setting mechanical or cement plugs, retrieving equipment, and cutting casing sections more efficiently than traditional rig-based abandonments, thus lowering both costs and environmental impacts.

- Offshore and Restricted Environments: Rigless interventions offer an efficient solution in environments with limited space or restricted platforms or wells that don't allow rigs. Coiled tubing units can be quickly mobilized, cutting setup times in half.

By leveraging these applications, operators maximize efficiency, reduce costs, and extend the productive life of wells—all while maintaining safety and operational flexibility.

Benefits of Rigless Well Intervention

Rigless well intervention offers numerous advantages that make it an increasingly preferred choice in the oil and gas industry. One of the most significant benefits is cost reduction. By eliminating the need for heavy drilling rigs, operators can drastically cut mobilization, equipment, and personnel expenses. Additionally, rigless interventions typically require less setup time, enabling quicker responses to well issues and minimizing production downtime.

Rigless techniques offer another key advantage by enabling live well interventions, meaning work can be carried out without killing the well or stopping production - an essential factor for optimizing asset uptime and profitability. Furthermore, they're highly adaptable, capable of meeting diverse challenges like well cleanouts or enhanced stimulation while simultaneously having less of an environmental impact due to reduced footprint and emissions.

Overall, rigless well interventions combine efficiency, flexibility, and sustainability, helping operators extend well life and improve long-term performance.

In A Word

Rigless well intervention has revolutionized the oil and gas industry by offering efficient, safe, and cost-effective ways of well maintenance and optimization. By employing advanced techniques such as wireline logging, coiled tubing, and snubbing, operators can maximize oil and gas production.

Rigless interventions offer operators looking to boost well performance without incurring the costs associated with hiring an entire rig an ideal solution.