The Role of Hybrid Oil Drilling Techniques

For a long period of time, oil drilling has been the backbone of the world’s energy supply, continuing to evolve as the dependency on value chains of oil has increased. In the early days, oil drilling relied on purely mechanical systems, however, with reservoirs becoming more complex and standards becoming more holistic, more value has been placed on multi-pronged approaches. In innovation, hybrid oil drilling techniques represent this evolution where traditional practices are coupled with advanced digital, hydraulic and renewable practices for improved performance, safety and sustainability.

What are Hybrid Oil Drilling Techniques

Hybrid oil drilling techniques are systems that integrate several oil drilling techniques in a single system aiming at optimization in performance. Rather than relying on the conventional rotary drilling system alone, and the recent directional drilling system, hybrid drilling systems incorporate rotary-steerable systems, mud motors, managed pressure drilling(MPD) and other systems, and a high degree of automation. The objective is to combine the best features of the systems while eliminating their downsides.

Key Types of Hybrid Oil Drilling Systems

| Type | How It Works | Key Advantages |

| Rotary–Percussive Hybrid | Combines continuous rotary motion with percussive impacts to penetrate rock formations. | Faster penetration rates, reduced bit wear, improved efficiency in hard rock. |

| Hybrid Directional Drilling | Integrates rotary steerable systems (RSS) with mud motors for precise directional control. | Enhanced trajectory accuracy, longer horizontal sections, reduced non-productive time. |

| Managed Pressure + Conventional Hybrid | Switches between conventional open circulation and managed pressure drilling as required. | Safer drilling in HPHT environments, better wellbore stability, reduced blowout risk. |

| Hybrid Energy-Powered Rigs | Combines diesel engines with batteries and renewable energy sources for rig power. | Lower emissions, reduced fuel costs, stable energy supply in remote areas. |

| Digital–Mechanical Hybrid | Integrates real-time data analytics, automation, and machine learning with traditional rig systems. | Optimized drilling performance, predictive maintenance, reduced downtime. |

Applications of Hybrid Drilling Techniques in the Oil and Gas Industry

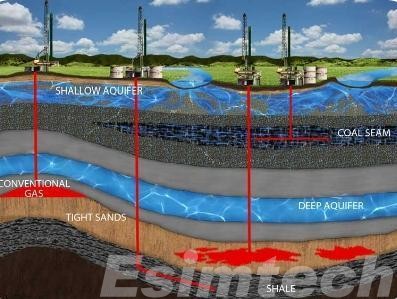

Shale Gas and Tight Oil Development

One of the most important areas of application of hybrid drilling techniques is the extraction of unconventional resources, especially shale gas and tight oil wells. These reservoirs need specific directional drilling to optimize the contact area with the hydrocarbons. Rotary steerable systems integrated with mud motors and hybrid directional systems ensure precise well placement and increased horizontal well drilling. This improves production and lowers costs, which is why hybrid systems are used in shale development projects around the globe.

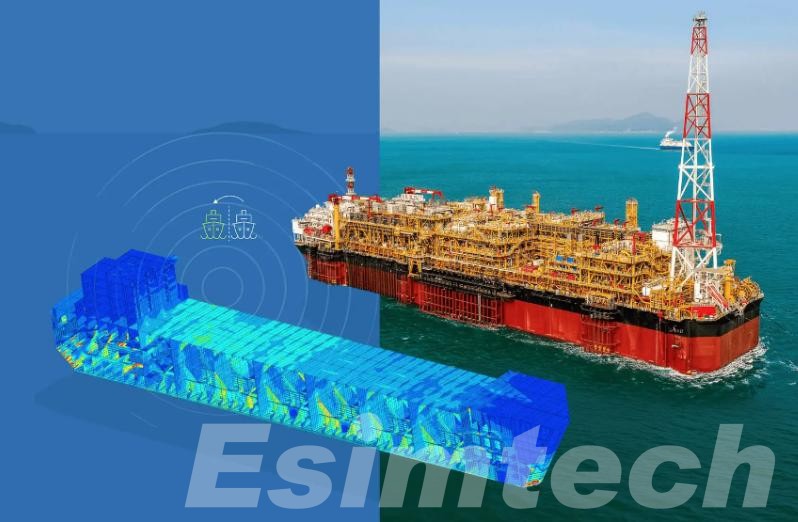

Deepwater and Offshore Drilling

Like other types of drilling, offshore drilling comes with its fair share of issues, both technical and environmental, and is even more numerous in deepwater drilling. Techniques such as managed pressure drilling and ‘hybrid’ techniques with other more traditional methods allow operators to control the stability of the wellbore under high and unpredictable temperatures and pressure. Above all, hybrids where diesel engines are used with battery-pack and other renewable energy sources are more common in the offshore sector as they minimize emissions and guarantee dependable power. These innovations improve the level of safety and operational sustainability in offshore works.

Extended-Reach Drilling (ERD)

Extended-reach drilling is more complex than conventional drilling and requires meticulous engineering to reach deep seated reservoirs. The integration of rotary steerable systems with real-time telemetry engineering and digital drilling allows drillers to steer and maintain multiple drill holes at accurate spaced intervals along the horizontal planar. This is imperative for fields in which vertical holes alone cannot be drilled, as it allows the drilling of otherwise inaccessible sources.

High-Pressure and High-Temperature (HPHT) Reservoirs

HPHT reservoirs, in which classic methods suffer severe limitations, can benefit from advanced oil drilling technologies. The integration of managed pressure drilling with conventional circulation along with the application of hybrid rotary-percussive methods to drill through difficult rocks enables operational safety along with effective drilling. This diminishes the possibility of blowouts or equipment failure, which stabilizes the extreme well conditions.

Environmentally Sensitive and Remote Areas

The pressure to reduce the environmental footprint of the industry is stimulating the use of hybrid energy systems in the operational drilling. Diesel batteries and renewable sources hybrid energy rigs reduce the consumption of fuel and carbon emissions to the atmosphere. Such systems are very advantageous when drilling in sensitive ecosystems or remote areas with a high emphasis on sustainability. Another benefit that remote areas offer is the less cumbersome logistics of fuel supply.

Challenges in Hybrid Oil Drilling Techniques

| Challenge | Description | Impact on Operations |

| Technical Complexity | Integration of rotary, percussive, directional, and digital systems increases operational complexity. | Requires highly skilled operators and can lead to higher training and operational costs. |

| Equipment Wear and Maintenance | Hybrid operations place varying stresses on drill bits, motors, and rig components. | Increases risk of equipment failure and non-productive time if not managed properly. |

| High Initial Investment | Advanced hybrid rigs and digital systems require significant upfront capital. | Can be a barrier for smaller operators or limit deployment in cost-sensitive projects. |

| Data Management Challenges | Real-time monitoring and digital twin systems generate massive amounts of data. | Requires robust IT infrastructure and expertise to process and utilize information effectively. |

| Environmental and Regulatory Compliance | Operating in HPHT zones, offshore sites, or sensitive ecosystems demands strict adherence to regulations. | Adds operational complexity and may limit flexibility if hybrid systems are not fully compliant. |

| Energy Integration | Hybrid energy systems combining diesel, batteries, and renewables can be difficult to manage. | Improper integration may reduce rig reliability or increase operational risks. |

| Adaptability to Formation Variability | Unexpected geological changes can challenge hybrid systems. | May require rapid adjustments, increasing the risk of non-productive time and safety hazards. |

How Simulation Technologies are Used for Optimizing Hybrid Oil Drilling Techniques

Through the development of virtual environments and processes, simulation tools help operators optimize hybrid oil drilling strategies prior to and during field operations.

1. Training and Skill Development

One of the prime uses of simulation technologies in hybrid drilling is the preparation of the workforce. Crews working on hybrid systems need to acquire skills on the traditional drilling techniques as well as the digital and advanced pressure systems. Drilling training simulators help operators and engineers to practice contouring complex systems without the danger and expense of live operations. This practice approach builds operator confidence and mitigates the risk of human error in the field.

2. Well Planning and Design Optimization

Simulation tools are valuable and crucial in the planning phase of hybrid drilling projects. By creating models of various geological shapes, engineers can evaluate the most efficient combinations of the rotary, percussive, and directional drilling techniques for particular formations. Drilling and well control simulations can be used to target and evaluate the points at which rotary–percussive drilling can be used to maximize penetration rates in hard rock, or where hybrid steering systems need to be used for extended-reach wells. These help in optimizing planning and reducing uncertainty regarding the well trajectory.

3. Real-Time Drilling Support

Apart from the pre-drilling design, simulation advancement also provides operational decision support in real time. Advanced digital twins allow operators to monitor hybrid systems in real time by digitally replicating downhole conditions. If something unexpected happens, like changes in formation pressure, mud weight changes, or even switching to managed pressure drilling, real time simulations can help model possible outcomes. Predicting outcomes enhances safety and efficiency.

4. Performance Evaluation and Predictive Maintenance

Substantial increase of risk of wear and tear of equipment or equipment malfunction is caused by the simultaneous operational use of multiple systems. Simulation technologies help address this by enabling maintenance schedule models. Based on the wear and tear simulation on drilling bits, motors, and the rig and other systems during different hybrid operations, operations can predict possible failure. Less down time, longer equipment life, and improved cost efficiency is a result of the maintenance being proactively scheduled.

5. Environmental Impact Assessment

As hybrid systems currently in use progressively adopt renewable sources of power and pressure mmanagement, the relications of the nepsitech on the environment and use of simulations to predict changes in it, becomes increasingly important. Models can provide estimates on the amount of fuel, emissions, and waste that different drilling approaches can produce. This serves operators aiming to retain hybrid operations at a negligeable impact on the environment, tracking more stringent, even self-imposed, sustainability goals and regulations.

Future Outlook of Hybrid Oil Drilling Techniques

Increasing Role of Automation and Artificial Intelligence

The future of hybrid oil drilling is likely to include AI and Automation more deeply than ever before. The drilling rigs of today are beginning to adopt more advanced technologies including digital twin models and overarching real-time monitoring systems. However, the next-generation rigs will delve even deeper, implementing predictive analytics and autonomous decision-making functionality. Hybrid rigs equipped with AI will have the capability to optimize drilling parameters in real-time and will be able to seamlessly adapt to sudden changes in formations. More importantly, there will be reduced reliance on manual oversight. This will provide higher efficiency and greater safety.

Expansion of Digital Twin Applications

The evolution of hybrid drilling will be defined by the virtual applications of digital twin technologies. Operators will visualize and rehearse the execution of different hybrid approaches in order to plan ahead by forming precise virtual clones of the wells and drilling systems. Lifespan of critical drilling equipment will be extended while minimizing downtime, as digital twins will be able to maintain operations that focus on real-time data correction and rest to optimize predictive maintenance.

Hybrid Energy Integration for Sustainability

With the rising environmental concerns, the use of drilling rigs operated on both conventional, and renewable energy sources will further increase hybridization. The addition of batteries, solar panels, and even offshore winds with diesel generators will minimize fuel usage and emissions. These hybrid energy systems support the efforts of global goals to reduce carbon emissions while supporting remote and offshore drilling. In the future, fully electrified hybrid rigs may become the standard for environmentally sensitive pilot projects.

Enhanced Performance in Complex Reservoirs

Hybrid oil drilling methodologies will still demonstrate their relevance on unconventional tidewater, extreme water depths, and HP/HT formations. It is anticipated that upcoming technology will produce higher rates of penetration, better directional drilling, and overall stabilized boreholes. This will increase the hybrid drilling industries ability to perform, and provide safe access to previously inaccessible oil, and gas reserves, making hybrid drilling a crucial component of resource recovery.

Integration with Robotics and Remote Operations

Incorporating robotics and remote operation centers will also influence the future of hybrid drilling. Tripping pipe and other monotonous or dangerous tasks can be assigned to robots, which reduces the risk to human personnel. Remote drilling, paired with hybrid digital-mechanical systems, will enable specialists to control multiple rigs from central control stations, reducing costs and enhancing collaboration on global projects.

Final Thoughts

Hybrid oil drilling techniques are the critical step in efficient and sustainable energy extraction. Oil drilling systems with advanced technology provide increased adaptability, safety, and performance. As the demand for hydrocarbons continues to rise amidst efforts to make operations more environmentally friendly, hybrid drilling offers an optimal answer to the industry’s most challenging new problems.