What are the Advanced Oil Well Workover Techniques for Mature Fields

Mature oil fields represent a unique challenge to producers, from reservoir pressure depletion to older equipment and increased operating risk. To maintain production and extend the life of such wells, it is important to employ more sophisticated oil well workover techniques. Well workover, a cornerstone of oil and gas workover operations, is a well-planned intervention to re-establish or enhance the productivity of a well with little downtime and cost.

In this paper, we will address the primary challenges of workover in old fields, outline best practices—mechanical workover, coiled tubing, acidizing, and high-end downhole tools—and indicate the need for well workover simulators to train the next generation of oilfield professionals. Familiarity with these techniques allows operators to maximize production, improve safety, and make smart choices for long-term field optimization.

What is Oil Well Workover?

Workover, also known as well servicing, is the set of operations done on existing wells in oil or gas to restore, maintain, or improve productivity. Unlike general servicing that is often used, workover requires much more effort, such as re-perforating, downhole equipment replacement, or even sidetracking the wellbore.

For mature oil fields, executing workover is not just critical for addressing problems such as declining water or gas, sand production, or the loss of pressure or mechanics of the well; it is essential for improving productivity from old reserves. These operations are ideal for sustaining pressure depletion, sand, water, or gas breakthrough, or failure of any other component of the well. All of this is done to achieve the maximum recovery factor of the oil well. It is done in an efficient, cost-effective manner.

Challenges in Workover of Mature Fields

Workover operations in mature oil and gas fields have their own peculiar and complex set of issues that distinguish them from workover operations in the newer fields. The fields, in the latter half of their production cycle, require a delicate blend of technicality and caution in undertaking oil and gas workover. The dominant challenges are:

- Reservoir Pressure Decline and Depletion: Pressure depletion is typically found in mature reservoirs. This low-pressure environment places the formation at higher risk for severe damage during workover. Lost circulation becomes a major problem, where the workover fluid is lost to the formation instead of being circulated to the surface and potentially plugging pore spaces and reducing permeability further.

- Well Integrity Issues: After several decades of production life, the mechanical integrity of the well itself is normally degraded. Casing corrosion, deterioration of the cement sheath, and tubing leaks are common. Not only do these issues complicate the workover of the well (e.g., it is difficult to set plugs or packers), but they also pose severe well control risks unless properly diagnosed and treated.

- Unwanted Fluid Production: Rising levels of unwanted fluids, primarily water and/or gas, are one of the diagnostic issues. Careful identification of the origin of unwanted fluids—channeling behind the casing, coning from aquifers beneath, or breakthrough from adjacent fractures—must be made. Without sophisticated diagnostic methods, a workover that is designed to increase oil production may actually increase water cut.

- Economic Margins and Risk: The biggest challenge will probably be the narrow economic margin for error. The investment in oil well workover techniques for mature reservoirs has to be backed up by a repeatable and sustainable level of production increment. Operators are continually faced with the dilemma of selecting the most economically efficient intervention from a range of high-tech options, where the economic risk of failure is high.

These challenges require more than standard procedures; they require advanced diagnostics, meticulous planning, and innovative techniques to ensure that workover campaigns successfully maximize the productive life of these valuable assets.

Advanced Oil Well Workover Techniques

To complete the oil well workover in the mature fields, it is important to integrate both modern and ancient methods to fix problems such as declining production, equipment deterioration, and complicated reservoir issues. Down below, let’s investigate the most notable methods and their functions.

Mechanical Workover

Mechanical workover is one of the most basic techniques in oil and gas workover operations. It includes replacing, inspecting, physically removing, and repairing the equipment that is installed down the hole in the well, such as packers, tubing, and pumps.

In mature wells, mechanical workover is useful to repair problems brought about by aging infrastructure. These primary issues, such as high corrosion of packers and tubers, can be addressed to regain production and efficiency. Even though the process is tediously slow, it enables operators to examine wellbores thoroughly, fix mechanical failures, and make appropriate repairs.

Key Concentrations

- Strategic planning is needed to minimize downtime.

- Most suitable for the well with the most severe mechanical damage.

- Frequently, stimulation and other methods of intervention are used.

Coiled Tubing Workover

Coiled tubing workover utilizes flexible, continuous tubing to carry out interventions with only partial removal of production tubing. This method is more popular in mature oil fields due to the fact that it enables partial continuation of production and minimizes downtime.

Some applications of coiled tubing workover are:

- Removal of scale or debris in the wellbore

- Acidizing or fracturing operations

- Carrying out minor downhole repair or logging

The advantages are self-evident: reduced risk compared to mechanical workover, suitability for deviated or horizontal wells, and faster application. Operators must carefully watch tubing fatigue, however, and treat it appropriately to avoid problems on seasoned wells.

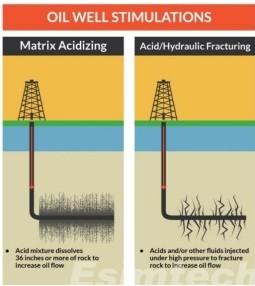

Acidizing & Well Stimulation

Acidizing and well stimulation are necessary in rejuvenating productivity in old fields where production is hindered by formation damage, scale, or lesser permeability.

- Matrix Acidizing treats the near-wellbore zone to dissolve deposits and improve fluid flow.

- Fracture Acidizing creates new pathways in low-permeability reservoirs to improve recovery.

If used judiciously, stimulation can contribute high rates of production without requiring widespread mechanical interference. In older fields, selective acid placement and careful reservoir evaluation have to be practiced to avoid hurting the formation.

Professional Insight: In the majority of older reservoirs, the combination of workover with selective acidizing will produce the most desirable compromise between enhanced production and operating efficiency.

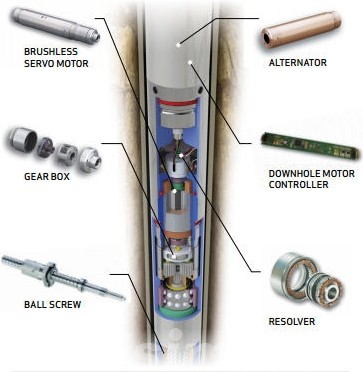

Downhole Tools & Automation

Sophisticated downhole tools and automation are increasingly crucial to contemporary oil well workover for the sake of enhanced efficiency and safety. Smart packers, logging tools, and real-time sensors enable operators to sense conditions in the wellbore and make decisions based on facts. Automated rigs and remote-operated machines reduce human interaction with high-risk tasks and enhance accuracy.

In mature fields, where pressures on wells are uncertain or casing is lightheaded, automation and high-accuracy downhole equipment can prevent accidents, optimize interventions, and reduce operation costs.

Key Takeaways:

- Automation integration increases safety and efficiency

- Data-driven monitoring allows for tailoring of interventions to the well conditions

- Enhance results when combined with traditional methods like mechanical or coiled tubing workover

Role of Well Workover Simulators in Training

Well workover simulators have now become an integral part of modern oil and gas workover operations, particularly for training personnel to handle complex situations in mature fields. Simulators provide a life-like, risk-free environment where engineers and technicians can practice interventions, troubleshoot probable maladies, and refine decision-making ability before exposure to the field.

In aged oil wells, the danger is greater: aged equipment, ambiguous reservoir behavior, and safety risks complicate practical training. Simulators replicate real well conditions, including mechanical failure, pressure fluctuations, and operating restrictions, so students can experience situations that are too unsafe or costly to train on actual wells.

Big Gains of Well Workover Simulators:

- Enhanced Safety – Operators have the opportunity to practice different workover techniques, i.e., mechanical workover or coiled tubing intervention, without endangering personnel and equipment.

- Better Operation Efficiency – Trainees learn how to plan and perform interventions efficiently, reducing downtime during actual well workover operations.

- Advanced Field Development Expertise – Simulators provide the capability of simulating the unique problems of a mature field, with personnel able to develop skills in resolving issues like tubing wear, damage to formation, or pressure drop.

- Standardization of Excellence – By utilizing the environment of controlled learning, simulators standardize team practices so that methodologies for mature fields’ oil well workover can be applied uniformly.

Moreover, adding simulation-based training to an operator’s curriculum enhances confidence and competence, and the outcomes translate into safer, more effective field operations on a direct basis. For those companies wanting to maximize production and maximize the lifespan of older wells, investing in well workover simulators is no longer an option—it is a strategic necessity.

Final Thought

The oil well workover techniques for mature fields are necessary in sustaining productivity, enhancing performance, ensuring the safety of the operations, and the well-being of the ecosystem. Each technique, including but not limited to mechanical and coiled tubing, well acidizing and stimulation, downhole automation, and others, attempts to solve the peculiar problems presented by the aged wells. Workover simulator software, in particular, augments the training of engineers and technicians to improve their performance in complex scenarios, minimizing the risks and the needed downtime. Combining technical experience and simulation training, oilfield operators can increase the efficiency and longevity of mature wells while maintaining the safety and proper handling of oil and gas wells’ workover operations.