Why Choose Well Control Simulators In The Oil And Gas Industry

Well control, which involves maintaining the pressure and fluids in the wellbore, is a vital part of drilling operations to avoid unintentional hydrocarbon release. Well control simulators have been developed as a key training tool for improving the expertise and preparedness of drilling workers.

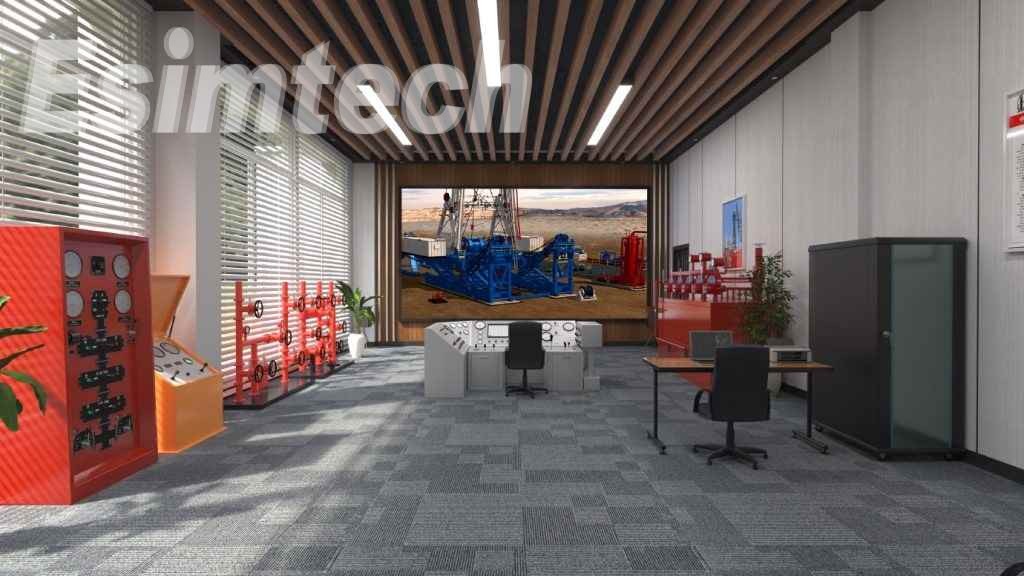

What Are Well Control Simulators

Well control simulators are sophisticated training tools that simulate the real-world well control environment in a controlled and safe environment. These simulators employ cutting-edge technology to create a virtual well control experience that allows trainees to practise well control procedures and techniques without risk of real-world repercussions. They provide a risk-free environment in which drilling workers can refine their well control skills, improve their decision-making ability, and acquire hands-on experience.

Advantages Of Well Control Simulators

The capacity to reproduce real-world well control scenarios is one of the primary benefits of well control simulators. These simulators may simulate a variety of well control circumstances, such as various sorts of kicks, blowouts, and other pressure-related occurrences. They can also provide a realistic training experience by simulating various types of wells, geology, and drilling equipment. Trainees can practise well control techniques in a controlled setting, such as shutting in the well, circulating out kicks and killing the well, giving them confidence and proficiency in dealing with well control issues in the field.

Portable well control simulators can allow trainees to become acquainted with the functioning of well control equipment and systems. They can practise operating several types of well control equipment, such as blowout preventers (BOPs), choke and kill manifolds, and pressure control systems, to improve competency. This hands-on training enables trainees to develop muscle memory and reflexes, both of which are essential in high-pressure well control scenarios.

It enables students to practise well control methods in a dynamic and realistic environment. These simulators are outfitted with sophisticated monitoring systems that continuously measure wellbore pressure, temperature, and other characteristics. Trainees can practise reacting to changing wellbore conditions, such as pressure and temperature variations, and making the appropriate modifications to maintain well control. This dynamic training environment aids trainees in developing quick thinking, decision-making, and problem-solving abilities, all of which are essential in well control operations.

The capacity to provide fast feedback and assessment is another key advantage of excellent control simulators. These simulators continuously monitor trainee performance and provide feedback on a variety of factors such as wellbore pressure, choke and kill line pressure, and mud characteristics. This feedback loop enables learners to analyse their performance and alter their well control measures as needed. Trainees can also analyse their strengths and weaknesses after the simulation session and work on improving their skills and knowledge.

Customized Well Control Simulators From Esimtech

Esimtech, a company that specialises in simulation systems for petroleum engineering and petroleum equipment, can create customised well control simulators to satisfy the specific training requirements of various drilling operations. They can be customised to mimic the features of various wells, formations, and drilling equipment, offering a realistic training experience. Simulators can also be configured to simulate different well control scenarios, such as shallow gas kicks, deep water well control, and high-pressure/high-temperature (HPHT) well control, allowing trainees to practice handling different well control situations they may encounter in the field.

Summary

Well control simulators provide immediate feedback and assessment, can be customised to meet specific training needs, and facilitate team training and collaboration, all of which play an important role in improving drilling personnel’s competency and preparedness, ultimately contributing to the safety and efficiency of drilling operations in the oil and gas industry.