Fixed Offshore Platforms vs. Mobile Offshore Rigs: A Definitive Guide

Offshore structures play a crucial role in the exploration and extraction of oil and gas from beneath the ocean floor. Two primary types of offshore installations, Fixed Offshore Platforms and Mobile Offshore Rigs, serve as essential components in the offshore energy industry. In this definitive guide, we will explore the characteristics, applications, and design considerations of both fixed platforms and mobile rigs, providing insights into their respective advantages and limitations.

Mobile Offshore Rigs

1. Types of Mobile Offshore Rigs

Mobile offshore rigs are designed for flexibility and adaptability, allowing them to explore and drill in various locations. The main types of mobile rigs include:

- Jack-up Rigs: These rigs have legs that can be lowered to the seabed, providing stability during drilling operations. Jack-up rigs are commonly used in shallow waters and can be raised to move to new locations.

- Semisubmersible Rigs: Floating on the water surface, semisubmersible rigs can be partially submerged to increase stability during drilling. This flexibility makes them suitable for exploration in different water depths.

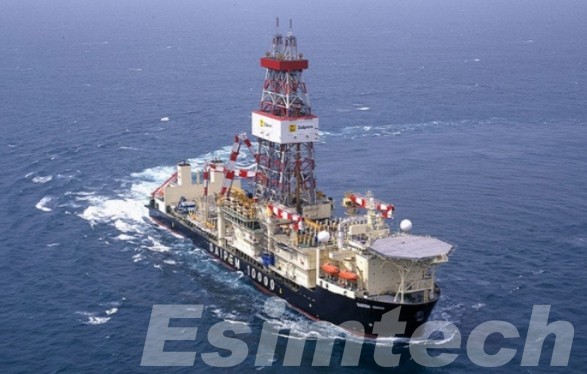

- Drillships: Self-propelled vessels equipped with drilling capabilities, drillships are highly mobile and can operate in deep waters. They offer flexibility in exploration and drilling activities.

2. Applications of Mobile Offshore Rigs

Mobile rigs are versatile and find applications in a variety of offshore activities, including:

- Exploratory Drilling: Mobile rigs are particularly useful in unexplored or remote regions where fixed platforms may not be feasible. Their mobility allows for quick deployment to explore new and potentially lucrative areas.

- Temporary Operations: Mobile rigs are well-suited for short-term projects or situations where frequent relocation is necessary. This adaptability makes them valuable for exploration campaigns with changing operational requirements.

3. Mobility and Flexibility of Mobile Offshore Rigs

One of the key advantages of mobile rigs is their ability to move from one location to another swiftly. This mobility is essential for adapting to changing exploration scenarios and reaching remote or challenging offshore sites.

The flexibility of mobile rigs allows operators to explore different geological formations and respond to evolving market conditions. This adaptability is particularly advantageous in the dynamic and ever-changing landscape of the offshore energy industry.

4. Technological Advancements of Mobile Offshore Rigs

Ongoing technological advancements in drilling and exploration equipment contribute to the efficiency and capabilities of mobile offshore rigs. These advancements include:

- Automation: The integration of automation technologies enhances the safety and productivity of drilling operations on mobile rigs. Automated systems can perform complex tasks with precision, reducing the risk of human error.

- Advanced Equipment: Continuous innovation in drilling equipment, sensors, and data analytics improves the overall performance and reliability of mobile rigs. Enhanced equipment contributes to more accurate drilling and exploration outcomes.

Fixed Offshore Platforms

1. Types of Offshore Platforms

Fixed offshore platforms are engineered to withstand the forces of the open sea while providing stable platforms for drilling and production activities. The main types include:

- Jacket Platforms: These structures, supported by vertical legs secured to the seabed, are commonly used in shallow waters. Their design offers stability for various offshore activities, including drilling and production.

- Compliant Towers: Engineered for deeper waters, compliant towers are flexible structures that can absorb wave and wind forces. This flexibility allows them to remain standing even in harsh environmental conditions, making them suitable for challenging offshore locations.

- Gravity-Based Structures: These platforms utilize their own weight to resist the forces of the sea. Positioned on the seabed, they are versatile and can be adapted for a range of water depths, providing a stable foundation for offshore operations.

2. Applications of Offshore Platforms

Fixed platforms serve diverse purposes, each tailored to specific offshore requirements. The key applications include:

- Drilling and Production Platforms: Equipped with drilling rigs and production facilities, these platforms are central to the extraction and processing of oil and gas. They provide a stable foundation for long-term operations.

- Living Quarters Platforms: Essential for offshore personnel, these platforms offer accommodation facilities, catering to the living and working needs of the workforce stationed in remote offshore locations.

- Wellhead Platforms: Focused on housing wellheads and initial processing equipment, these platforms play a critical role in the early stages of resource extraction.

3. Design and Construction of Offshore Platforms

The design and construction of fixed platforms involve intricate engineering and meticulous planning to ensure structural integrity and resilience against environmental forces. Key considerations include:

- Structural Integrity: Rigorous engineering standards are applied to ensure stability and durability in the face of waves, wind, and other environmental factors. These platforms are designed to withstand the challenging conditions of the open sea.

- Fabrication: Construction often takes place onshore, where the various components of the platform are fabricated. Once assembled, the platform is transported to the designated offshore location for installation.

Comparison of Fixed Offshore Platforms and Mobile Offshore Rigs

Fixed offshore platforms and mobile offshore rigs are the workhorses of the oil and gas industry, extracting resources from the depths of the ocean. But they differ significantly in their capabilities, limitations, and impact. Here provide a sheet to summarize the difference.

| Feature | Fixed Platforms | Mobile Offshore Rigs |

| Depth of Operation | Shallow & Medium (up to 300 meters) | Deep (300 meters – 3,000 meters) |

| Mobility | Permanently anchored | Relocatable to different sites |

| Applications | Long-term production, processing, storage | Exploratory drilling, well interventions |

| Cost | High upfront | Lower upfront, higher operational |

| Environmental Impact | Smaller footprint, complex decommissioning | Larger footprint, potential spills/noise |

| Design & Construction | Various types (jacket, gravity, TLP, semi-sub), steel/concrete/composites, onshore fabrication | Jack-up rigs, drill ships, semi-sub, steel, shipyard built |

| Weather Limitations | More resistant | Affected by high waves/currents |

| Maintenance & Repair | Challenging access | Easier access, quicker turnaround |

| Safety Measures | Stringent protocols | Stringent protocols |

Conclusion

In summary, the decision between fixed offshore platforms and mobile offshore rigs depends on the specific needs of each project. Fixed platforms prioritize stability and longevity, while mobile rigs emphasize flexibility and adaptability. Ongoing technological progress shapes the offshore energy sector, underscoring the importance of comprehending the strengths and limitations of each option for successful operations.

As the industry progresses, finding the right balance between fixed and mobile solutions becomes pivotal in optimizing exploration and extraction endeavors. Fixed platforms remain crucial for enduring operations in stable environments, whereas mobile rigs offer a dynamic solution for exploratory drilling and short-term projects. Successful offshore resource development requires a strategic and well-informed approach, considering the unique advantages of both fixed platforms and mobile rigs across various operational contexts.