How Does High-definition Well Logging Revolutionize Subsurface Exploration

High-definition well logging represents a significant advancement in the field of subsurface exploration and reservoir characterization. By leveraging cutting-edge technology, this method enhances the precision and detail of data collected from boreholes, providing geologists and engineers with a clearer and more accurate understanding of subsurface formations. This article delves into the essentials of high-definition well logging, its technological innovations, benefits, and its transformative impact on the oil and gas industry.

What is High-definition Well Logging

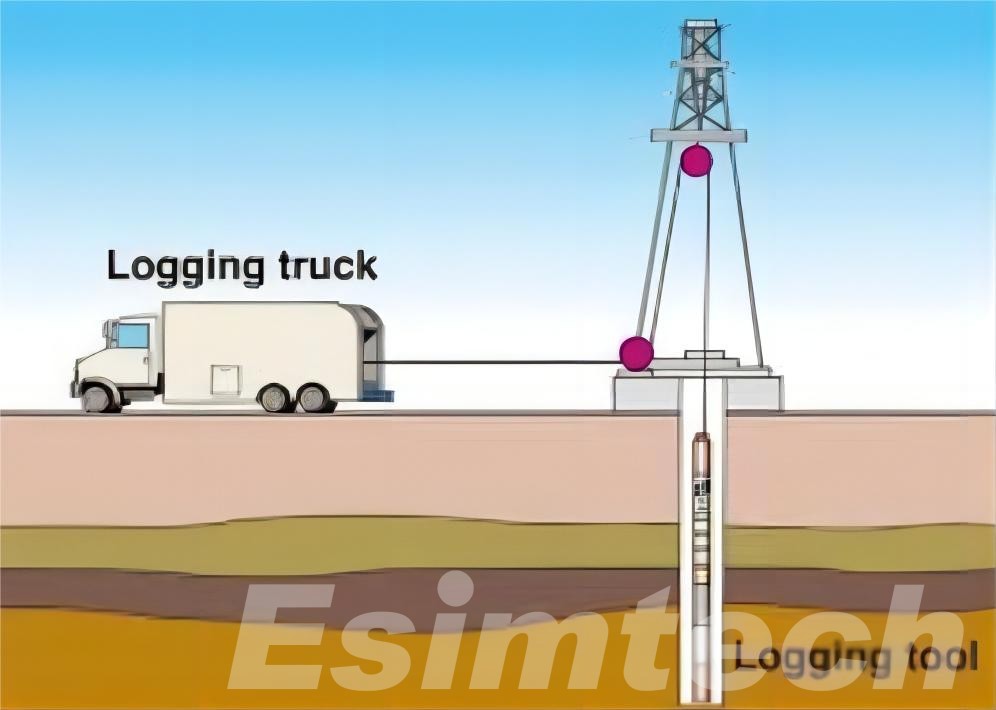

Well logging, also known as borehole logging, involves recording various geophysical properties of rocks and fluids encountered in boreholes. Traditionally, well logs have been essential for determining the lithology, porosity, permeability, and fluid content of geological formations. High-definition well logging takes this a step further by using advanced sensors and higher resolution data acquisition techniques to produce more detailed and accurate logs.

Technological Innovations Driving High-definition Well Logging

1. Advanced Sensor Technology

High-Resolution Sensors

Modern well logging tools are equipped with high-resolution sensors that can detect subtle variations in rock and fluid properties. These sensors capture data at a much finer scale than traditional tools, allowing for a more detailed and precise analysis of the subsurface.

Multifunctional Sensors

These sensors are often multifunctional, capable of measuring multiple parameters simultaneously. This capability reduces the need for multiple logging runs, saving time and reducing costs while providing a comprehensive data set.

2. Digital Signal Processing (DSP)

Enhanced Data Quality

Digital Signal Processing techniques have significantly enhanced the quality of data collected during well logging. DSP methods reduce noise and improve the signal-to-noise ratio, leading to clearer and more accurate readings.

Real-Time Analysis

Advanced DSP enables real-time data processing and analysis. This capability allows geologists and engineers to make immediate, informed decisions during drilling operations, enhancing efficiency and safety.

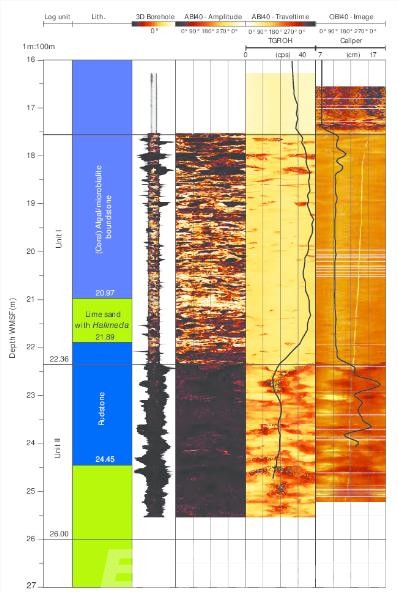

3. Borehole Imaging Tools

Microresistivity Imagers

Microresistivity imaging tools provide detailed visual representations of the borehole wall. These tools generate high-resolution images that reveal fine details such as fractures, bedding planes, and other geological features that were previously difficult to detect.

Ultrasonic Scanners

Ultrasonic borehole scanners use sound waves to create detailed images of the borehole’s interior. These tools are particularly effective in identifying small-scale features and anomalies, providing critical information for reservoir characterization.

4. Multicomponent Logging

Integration of Multiple Methods

Multicomponent logging integrates various logging techniques, such as acoustic, nuclear, and electromagnetic logging, into a single comprehensive logging run. This integration provides a more complete and multidimensional view of the subsurface, enhancing the accuracy and reliability of geological interpretations.

Cross-Disciplinary Data

By combining data from different logging methods, multicomponent logging provides cross-disciplinary insights that are crucial for understanding complex subsurface conditions.

5. Data Integration and Machine Learning

Advanced Data Integration

High-definition well logging benefits from sophisticated data integration techniques that combine data from multiple sources into a cohesive analysis. This integrated approach improves the accuracy and comprehensiveness of subsurface models.

Machine Learning Algorithms

Machine learning algorithms play a crucial role in interpreting the vast amounts of data generated by high-definition well logging. These algorithms can identify patterns and correlations that might be missed by traditional analysis methods, leading to more accurate predictions of reservoir properties and behavior.

6. Fiber Optic Technology

Distributed Sensing

Fiber optic technology enables distributed sensing along the length of the borehole. This innovation allows for continuous monitoring of temperature, pressure, and strain, providing a detailed picture of wellbore conditions in real time.

High-Resolution Data

Fiber optic sensors deliver high-resolution data that enhances the understanding of dynamic subsurface processes. This real-time monitoring capability is essential for optimizing drilling and production operations.

7. Nuclear Magnetic Resonance (NMR) Logging

Detailed Fluid Analysis

NMR logging provides detailed information about the types and quantities of fluids present in the pore spaces of rocks. This technique is particularly useful for distinguishing between oil, gas, and water, leading to more accurate reservoir characterization.

Improved Porosity and Permeability Estimates

NMR logging also enhances estimates of porosity and permeability, critical parameters for assessing reservoir quality and potential productivity.

Benefits of High-definition Well Logging

1. Enhanced Reservoir Characterization

Greater Detail and Accuracy

High-definition well logging provides a granular view of subsurface formations. By capturing high-resolution data, High-definition well logging allows for a more precise characterization of rock properties, fluid content, and geological structures. This detailed information is critical for accurate reservoir modeling and assessment.

Improved Identification of Geological Features

High-definition well logging tools, such as borehole imaging devices, can reveal fine details like fractures, bedding planes, and small-scale heterogeneities. This improved detection capability enhances the understanding of the geological environment, leading to better predictions of reservoir behavior.

2. Optimized Decision Making

Real-Time Data Analysis

Advanced digital signal processing and real-time data acquisition enable immediate analysis and interpretation of logging data. This allows geologists and engineers to make timely, informed decisions during drilling and production operations, reducing the likelihood of costly errors and non-productive time.

Enhanced Well Placement

With precise subsurface data, operators can optimize well placement to target the most productive zones. This leads to increased hydrocarbon recovery and improved well performance, maximizing the return on investment.

3. Increased Efficiency and Cost Savings

Reduced Need for Additional Wells

High-definition well logging provides comprehensive subsurface information from a single wellbore. This reduces the need for additional exploratory wells, significantly lowering drilling costs and minimizing environmental impact.

Streamlined Operations

By providing detailed and accurate data, High-definition well logging helps streamline drilling and completion processes. This reduces the time and resources required for these operations, leading to overall cost savings and increased operational efficiency.

4. Enhanced Production Strategies

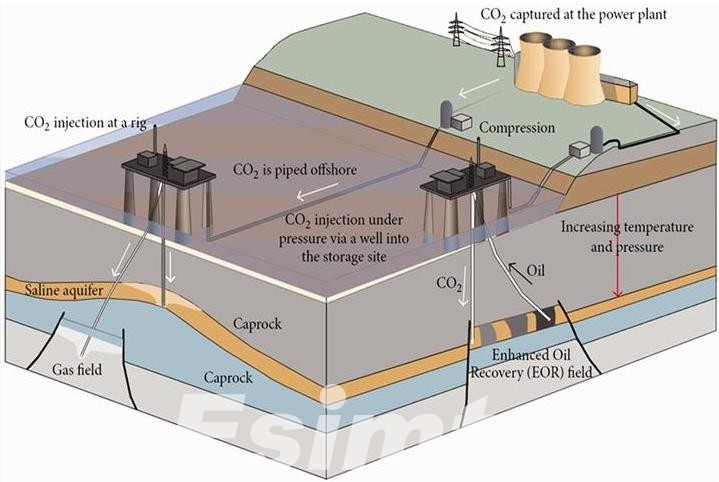

Improved Reservoir Management

Accurate data from High-definition well logging allows for better reservoir management and monitoring. Operators can implement more effective production strategies, such as enhanced oil recovery (EOR) techniques, to maximize hydrocarbon extraction.

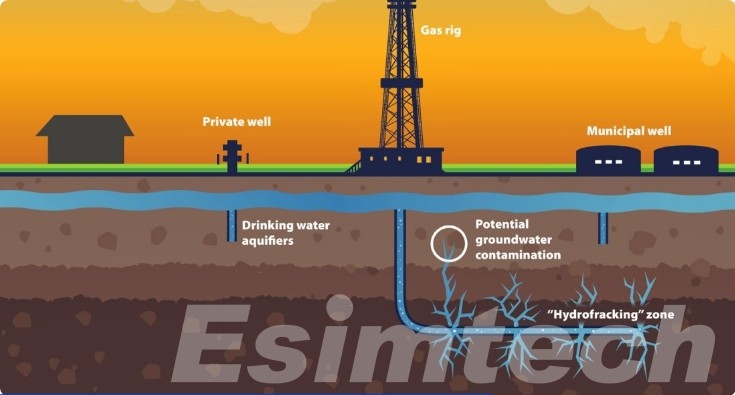

Optimization of Hydraulic Fracturing

In unconventional reservoirs, High-definition well logging is crucial for designing and optimizing hydraulic fracturing operations. Detailed logs help identify sweet spots and fracture networks, ensuring that fracturing efforts are precisely targeted for maximum efficiency and effectiveness.

5. Environmental and Safety Benefits

Hazard Identification

HDWL helps identify potential geological hazards, such as fault zones and unstable formations. This information is critical for planning safe drilling operations and mitigating risks, thereby protecting personnel and equipment.

Reduced Environmental Impact

By minimizing the need for additional wells and optimizing drilling and production strategies, HDWL contributes to a reduced environmental footprint. More efficient resource extraction translates to less surface disruption and lower emissions.

6. Advanced Data Integration and Interpretation

Comprehensive Subsurface Models

The integration of high-definition well logging data with other geophysical and geological information leads to more comprehensive and accurate subsurface models. These models are essential for understanding complex reservoirs and planning effective extraction strategies.

Leveraging Machine Learning

Machine learning algorithms can process and interpret the vast amounts of data generated by HDWL. These advanced analytical techniques can identify patterns and trends that might be missed by traditional methods, providing deeper insights into reservoir properties and behavior.

Applications of High-definition Well Logging in the Oil and Gas Industry

1. Unconventional Reservoirs

In unconventional reservoirs, such as shale gas and tight oil formations, high-definition well logging is essential for identifying sweet spots and optimizing hydraulic fracturing operations. Detailed logs help in understanding the complex geology and fracture networks of these reservoirs.

2. Enhanced Oil Recovery (EOR)

EOR techniques, such as water flooding and CO2 injection, rely on precise subsurface data to be effective. High-definition well logging provides the necessary information to design and monitor EOR projects, ensuring maximum hydrocarbon recovery.

3. Geothermal Energy

In geothermal energy projects, high-definition well logging aids in identifying heat-producing formations and evaluating the thermal properties of the subsurface. This information is critical for the efficient development of geothermal resources.

Key Simulation Technologies Used in High-definition Well Logging

1. Reservoir Simulation

Numerical Reservoir Modeling

Numerical reservoir modeling involves creating detailed computational models of the reservoir using data from high-definition well logging. These models simulate fluid flow, pressure distribution, and other dynamic processes within the reservoir, providing insights into its behavior and performance over time.

Finite Element Analysis (FEA)

FEA is used to simulate the mechanical behavior of the reservoir and wellbore structures under various conditions. It helps in understanding stress distribution, deformation, and potential failure points, ensuring the integrity and safety of drilling and production operations.

2. Seismic-Well Tie Simulation

Synthetic Seismic Generation

Synthetic seismic generation involves creating seismic responses from well log data to match with actual seismic surveys. This process helps in correlating well logs with seismic data, improving the accuracy of subsurface imaging and interpretation.

Seismic Inversion

Seismic inversion techniques use HDWL data to transform seismic reflection data into quantitative rock property models. This integration enhances the resolution and reliability of seismic interpretations, aiding in the identification of hydrocarbon-bearing formations.

3. Geomechanical Modeling

Stress-Strain Simulations

Geomechanical models simulate the stress and strain behavior of subsurface formations in response to drilling and production activities. These simulations help predict and manage issues such as wellbore instability, fracturing, and subsidence.

Pore Pressure Prediction

Pore pressure prediction models use high-definition well logging data to simulate the pressure conditions within the reservoir. Accurate pore pressure predictions are crucial for safe drilling operations, preventing blowouts and ensuring well control.

4. Petrophysical Modeling

Rock Physics Modeling

Rock physics models use high-definition well logging data to simulate the physical properties of reservoir rocks. The well logging simulation systems help in understanding the relationships between rock properties and well log measurements, improving the interpretation of log data.

Fluid Substitution Modeling

Fluid substitution models simulate the changes in well log responses due to different fluid types within the pore spaces. These simulations aid in distinguishing between oil, gas, and water zones, enhancing hydrocarbon identification and quantification.

5. Integrated Asset Modeling

Production Forecasting

Integrated asset models combine HDWL data with production data to simulate the performance of the entire reservoir over its lifecycle. These simulations provide production forecasts, optimize recovery strategies, and support decision-making for field development.

Field Development Planning

Field development planning models use high-definition well logging data to simulate various development scenarios, such as well placement, drilling sequences, and production strategies. These simulations help in identifying the most efficient and cost-effective approaches for developing the reservoir.

6. Flow Simulation

Multiphase Flow Simulation

Multiphase flow simulations model the simultaneous flow of oil, gas, and water within the reservoir and wellbore. These simulations provide insights into phase behavior, fluid interactions, and production challenges, optimizing well and reservoir performance.

Enhanced Oil Recovery (EOR) Simulation

EOR simulations use HDWL data to model the effectiveness of various EOR techniques, such as water flooding, gas injection, and thermal methods. These simulations help in designing and optimizing EOR projects for maximum hydrocarbon recovery.

7. Drilling and Completion Simulation

Wellbore Stability Analysis

Wellbore stability simulations use HDWL data to model the mechanical stability of the wellbore during drilling. These analyses help in selecting appropriate drilling fluids, casing designs, and drilling parameters to prevent wellbore collapse and other issues.

Hydraulic Fracturing Simulation

Hydraulic fracturing simulations model the propagation of fractures within the reservoir during fracturing operations. These simulations help in designing effective fracturing treatments, optimizing fracture networks, and enhancing hydrocarbon flow to the wellbore.

8. Real-Time Monitoring and Simulation

Real-Time Data Integration

Real-time monitoring systems integrate HDWL data with simulation models to provide continuous updates on well and reservoir conditions. These real-time oil and gas simulation systems enable real-time decision-making, improving the efficiency and safety of drilling and production operations.

Predictive Analytics

Predictive analytics models use HDWL data to forecast future well and reservoir behavior. These simulations help in identifying potential issues before they occur, allowing for proactive management and mitigation strategies.

Conclusion

High-definition well logging represents a transformative advancement in subsurface exploration. Through providing highly detailed and accurate data, it enhances reservoir characterization, optimizes decision-making, and improves the overall efficiency and safety of drilling and production operations.