How Oil Rig Simulators Revolutionize Offshore Oil and Gas Training

In the offshore oil and gas industry, operations are complex, demanding, and often hazardous. Oil rig simulators are used for preparing personnel for the high-risk environment of offshore drilling, enabling them to master operational procedures and enhance safety without exposure to the real-life dangers of an actual rig. These advanced simulators are becoming indispensable tools in training programs, offering a variety of benefits in terms of safety, efficiency and cost-effectiveness.

Understanding Oil Rig Simulators

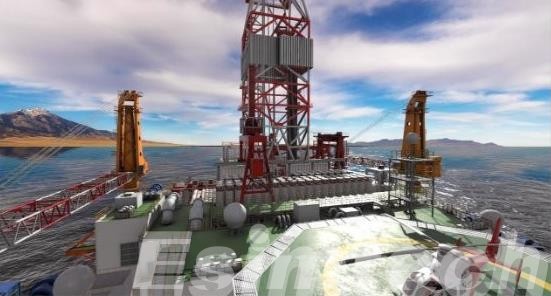

Oil rig simulators are highly sophisticated training systems designed to replicate the environment and operations of an actual offshore drilling rig. These simulators provide realistic virtual scenarios, allowing trainees to interact with the equipment, handle operational procedures, and make critical decisions, all in a controlled, risk-free setting. They often feature detailed graphics, real-time simulations, and real-world physics to create an authentic offshore environment.

The simulators typically consist of a combination of hardware and software that replicates key aspects of offshore operations, including drilling, safety protocols, emergency responses, and equipment handling. Trainers can customize scenarios to cover a wide range of conditions, from normal operation to extreme weather or crisis situations, to test the trainees’ decision-making and response capabilities.

How Oil Rig Simulators Work

Oil rig simulators are equipped with high-fidelity visuals, realistic control panels, and environmental effects such as weather conditions and sea states. They can replicate various types of rigs, including semi-submersible rigs, jack-up rigs, and drillships, allowing users to train for different offshore settings. Simulations are often customizable to reflect specific operational procedures, equipment configurations, and safety protocols.

This chart outlines the process of how oil rig simulators work, detailing the technological steps involved from setup to evaluation.

| Step | Description | Technological Process |

| 1. System Setup and Calibration | The simulator system is set up and calibrated to replicate real-world oil rig environments. | – Calibration of equipment and control systems to match real offshore rigs – Setting parameters for various rig systems |

| 2. Virtual Environment Creation | The virtual environment simulates an offshore oil rig, including its equipment and operational systems. | – 3D modeling and high-fidelity graphics create a lifelike rig environment – Accurate representation of equipment and control panels |

| 3. Scenario Configuration | Trainers configure scenarios (drilling operations, emergencies, maintenance) based on training objectives. | – Customizable scenarios to simulate different weather conditions, operational tasks, and emergency situations |

| 4. Trainee Interaction | Trainees interact with the simulator, controlling equipment, performing tasks, and responding to situations. | – User interfaces like touchscreens, joysticks, or VR/AR headsets allow trainees to operate equipment and control systems |

| 5. Real-Time Feedback and Data Collection | The simulator monitors trainee actions and decisions, providing immediate feedback and performance data. | – AI-based performance tracking – Real-time data analytics to assess trainee responses and decision-making |

| 6. Emergency and Risk Simulation | Simulates high-risk situations like blowouts, gas leaks, or equipment malfunctions for emergency response training. | – Crisis scenarios are triggered based on pre-configured conditions – Simulated environmental factors like stormy seas or equipment failure |

| 7. Multi-User Collaboration | Multiple trainees can interact within the same environment, each performing different roles on the rig. | – Multi-user support enables team-based training, with roles like driller, safety officer, or operator working together in the simulation |

| 8. Post-Training Evaluation | After training, detailed performance reports are generated, highlighting areas for improvement. | – Data-driven reports analyze decision-making, efficiency, and adherence to safety protocols – Trainers review the reports for feedback |

| 9. Scenario Replay and Optimization | Trainees can review their actions and replay scenarios to learn from mistakes and refine skills. | – Simulators offer replay functionality for reflective learning – AI suggests optimized actions and alternative responses |

| 10. Continuous Improvement and Updates | The simulator is updated regularly with new training scenarios, equipment models, and real-world data. | – Software updates integrate the latest rig technologies and operational procedures – Cloud-based updates allow for quick distribution of new training modules |

Key Types of Oil Rig Simulators

Oil rig simulators come in different types, each tailored to specific aspects of offshore drilling and operational training. These simulators allow trainees to practice various skills and procedures, from basic rig operations to complex emergency response protocols.

1. Drilling Simulator

Drilling simulators are designed to replicate the drilling process and provide a virtual environment where trainees can practice drilling operations. These simulators typically focus on:

- Drilling Operations: Training on the operation of drilling equipment, such as rotary tables, drawworks, and blowout preventers (BOPs).

- Well Control: Simulating scenarios for controlling a well, including blowout prevention and well control operations.

- Drill String Handling: Teaching how to manage the drill string, tripping operations, and making adjustments for various depths and pressures.

Drilling and well control simulators help operators develop essential skills in managing the equipment, preventing accidents, and responding effectively to unexpected situations.

2. Dynamic Positioning Simulator

Dynamic positioning simulators are used for training operators who manage the positioning of drilling rigs, ships, and floating platforms using thrusters, GPS, and other sensors. Key features include:

- Position Control: Simulating the control of a rig’s position in varying sea conditions, including wind, waves, and current.

- System Integration: Operators learn to manage the interaction between thrusters, sensors, and positioning systems to ensure the platform remains stationary during drilling or production.

- Navigation in Challenging Conditions: Simulating challenging environmental conditions such as storms, high waves, or changing currents, to test the crew’s ability to maintain control.

Dynamic positioning simulators are critical for training operators in maintaining the stability and safety of offshore drilling rigs and vessels.

3. Marine Safety and Emergency Response Simulator

Safety is paramount in offshore operations, and marine safety simulators focus on preparing personnel for emergency situations. These simulators are used for:

- Emergency Evacuation Drills: Simulating various emergency scenarios, such as fires, gas leaks, or severe weather, requiring quick decision-making for evacuation procedures.

- Fire and Gas Detection: Training personnel to respond to gas leaks, fires, or other hazardous situations on the rig, ensuring they can identify threats and initiate the appropriate safety protocols.

- Search and Rescue Operations: Simulating man-overboard scenarios and coordinating rescue efforts to save lives in dangerous offshore environments.

These emergency response training simulators help ensure that workers are prepared for the worst-case scenarios, improving safety and reducing the likelihood of fatalities or accidents.

4. Control Room Simulator

Control room simulators are used to train personnel responsible for monitoring and controlling the various systems on the rig. This type of simulator typically includes:

- Centralized Control Systems: Simulating the management of rig operations from the central control room, including equipment monitoring, well data analysis, and real-time decision-making.

- Integrated Systems: Training operators to handle complex control systems that integrate drilling, power, safety, and communication systems.

- Multi-Tasking and Crisis Management: Providing scenarios where operators must manage multiple systems and respond to emergency situations, testing their decision-making under pressure.

Control room simulators are essential for ensuring that operators can effectively manage the rig’s operations, troubleshoot issues, and respond to emergencies from the central command center.

5. Subsea Operations Simulator

Subsea simulators are designed to train personnel involved in underwater operations, including subsea drilling and construction. Key areas of focus include:

- Subsea Equipment Handling: Training on the operation of subsea systems, such as blowout preventers (BOPs), riser systems, and subsea robotics.

- Deepwater Drilling: Simulating drilling in deepwater and ultra-deepwater environments, including riser handling, well control, and fluid dynamics.

- Subsea Intervention: Providing training on performing maintenance, repair, and installation tasks on subsea equipment in challenging underwater environments.

Subsea simulators are vital for those involved in offshore projects where operations occur far below the surface, ensuring that personnel can handle high-pressure situations.

6. Oil and Gas Production Simulator

Oil and gas production simulators focus on the operational aspects of oil and gas extraction and processing. These simulators cover:

- Wellhead Control: Training on managing wellheads and the equipment used to control the flow of oil and gas from the reservoir.

- Production Optimization: Teaching how to optimize production rates, manage reservoir pressure, and troubleshoot production issues to maximize output.

- Surface Equipment Operation: Simulating the operation of surface equipment, such as pumps, separators, and compressors, to ensure efficient processing of oil and gas.

These simulators are ideal for training personnel involved in the production phase of offshore operations, helping them learn how to ensure the efficient, safe, and environmentally responsible extraction of resources.

7. Rig Maintenance and Equipment Simulator

Maintenance simulators focus on ensuring that rig personnel are equipped with the skills needed to keep all equipment in optimal working condition. These simulators include:

- Preventive Maintenance: Training on regular inspection, servicing, and upkeep of equipment to minimize downtime and prevent failures.

- Troubleshooting: Simulating equipment failures and teaching trainees to diagnose and repair issues efficiently.

- Equipment Familiarization: Providing virtual exposure to various types of equipment used on rigs, such as generators, pumps, and compressors, so that maintenance teams are familiar with their operation and potential issues.

Maintenance simulators help ensure that offshore rigs operate efficiently and minimize the risk of breakdowns, improving overall safety and operational performance.

8. Integrated Operations Simulator

Integrated operations simulators offer a comprehensive, all-encompassing training experience that integrates various aspects of offshore drilling and production. These simulators typically combine elements from drilling, dynamic positioning, control room operations, subsea work, and safety systems, allowing trainees to work through full-scale simulated operations. This type of simulator is useful for:

- Team Training: Providing a platform where multiple teams (e.g., drilling, production, and safety) can work together to simulate integrated offshore operations.

- Multi-Disciplinary Operations: Training individuals from various departments to collaborate effectively in a high-stakes, real-world offshore environment.

- Real-Time Decision Making: Offering scenarios that require trainees to make real-time decisions involving multiple facets of offshore operations.

Integrated operations simulators are especially useful for providing a holistic view of offshore oil and gas operations, fostering teamwork and improving overall operational coordination.

Key Benefits of Oil Rig Simulators

- Enhanced Safety and Risk Reduction

One of the most significant benefits of using oil rig simulators is the ability to train personnel in a risk-free environment. Simulators allow trainees to practice complex operations, such as handling dangerous equipment, managing well control, and responding to emergencies, without putting themselves, their colleagues, or the rig at risk. By simulating hazardous conditions such as blowouts, gas leaks, and fire emergencies, trainees can learn the proper safety protocols and decision-making skills necessary to mitigate real-life risks. This results in a workforce that is better prepared to handle emergencies safely, reducing the likelihood of accidents and costly mistakes on the job.

- Cost-Effective Training

Traditional oil rig training often involves sending personnel offshore, which can be expensive due to the costs associated with rig time, travel, and the use of equipment. Oil rig simulators eliminate many of these costs by allowing training to take place onshore in a controlled environment. This provides an affordable way to train large groups of personnel without disrupting ongoing operations. Additionally, simulators can be used repeatedly, which allows for more frequent training sessions and greater flexibility in scheduling, all while minimizing operational downtime and costs.

- Realistic, Hands-On Experience

Oil rig simulators provide an immersive and realistic environment that replicates actual offshore rigs. Trainees can interact with lifelike equipment and control systems, gaining hands-on experience with the tools they will use in real-world operations. This type of training ensures that personnel are not only familiar with theoretical concepts but also have the practical skills needed to perform their tasks efficiently. Whether it’s operating drilling equipment, managing a blowout preventer (BOP), or monitoring control systems, the simulation of real-world tasks allows trainees to develop the muscle memory and confidence needed for the job.

- Emergency Response Training

Oil rig simulators are crucial for teaching personnel how to respond effectively to emergencies. By simulating a wide range of crisis scenarios—such as fires, blowouts, man-overboard incidents, and gas leaks—these simulators provide a safe platform for trainees to practice emergency procedures without the danger of real-life consequences. The ability to rehearse emergency situations in a controlled setting builds muscle memory and improves decision-making under pressure. This type of training is critical for preparing workers to act quickly and confidently during actual offshore emergencies, reducing the chances of catastrophic outcomes.

- Scenario Customization for Targeted Training

Simulators allow trainers to customize training scenarios to fit the specific needs of the trainees. Whether focusing on routine operations, equipment troubleshooting, or high-risk emergency drills, simulators can adapt to target specific skills and challenges. Trainers can modify environmental conditions, equipment malfunctions, or operational complexities to create training scenarios that are relevant to the trainee’s role and level of experience. This customization ensures that each trainee receives the appropriate training tailored to their needs, helping them to develop a comprehensive skill set that addresses the demands of their specific job.

- Multi-User Capability for Team Training

Oil rig simulators often include multi-user functionality, allowing multiple trainees to interact within the same virtual environment. This feature is particularly valuable for team-based training, as it enables trainees to practice working together in real-world offshore scenarios. Crew members can take on different roles—such as rig operators, safety officers, and drillers—and collaborate to manage operations or respond to emergencies. This team-based training fosters improved communication, coordination, and decision-making among offshore personnel, ensuring that they are able to work seamlessly together in high-pressure situations.

- Real-Time Feedback and Performance Assessment

Oil rig simulators provide real-time feedback to trainees, allowing them to assess their performance and identify areas for improvement. By monitoring trainee actions and decisions during the simulation, the system generates detailed performance reports that highlight strengths and areas that need further development. This feedback helps trainers pinpoint specific skills that require attention, while also giving trainees an opportunity to refine their techniques and decision-making. The ability to track progress over time also allows for continuous improvement and ensures that trainees are developing the competencies needed to succeed in their roles.

- Adaptability to Various Training Needs

Oil rig simulators are versatile and can be used to train personnel across various disciplines within the offshore industry. Whether it’s drilling operations, well control, maintenance, or safety procedures, simulators can accommodate a wide range of training needs. The adaptability of these simulators ensures that they can be used for both entry-level training and advanced courses, catering to the needs of a diverse workforce. Additionally, simulators can be updated to include new technologies, equipment, and procedures, ensuring that the training program stays current with industry advancements.

- Environmental and Weather Condition Simulation

Simulators have the ability to mimic a wide variety of environmental and weather conditions that offshore rigs may face. These can include stormy seas, high winds, extreme temperatures, and other challenging conditions that affect offshore operations. By simulating these scenarios, trainees can learn how to manage operations in adverse conditions and develop the necessary skills to keep operations running smoothly regardless of external factors. This is particularly important for preparing personnel for extreme weather events, which can significantly impact the safety and efficiency of offshore operations.

- Increased Training Flexibility

Oil rig simulators offer flexibility in training schedules and locations. Training can be conducted at a dedicated training facility or even remotely, depending on the simulator’s capabilities. This flexibility makes it easier to accommodate shifts in workforce schedules and ensure that training sessions do not interfere with regular offshore operations. Additionally, simulators allow for training at any time, whether during off-peak hours or in preparation for a new shift, ensuring that personnel can receive training when it is most convenient and effective.

Technological Advancements in Oil Rig Simulators

This chart highlights the major technological advancements in oil rig simulators and their impact on improving the quality and realism of training for offshore personnel.

| Technological Advancement | Description | Impact on Training |

| Virtual Reality (VR) Integration | Incorporates immersive VR technology to create lifelike, interactive training environments. | – Enhances realism and immersion – Provides a fully interactive experience – Improves decision-making under pressure |

| Augmented Reality (AR) Features | Combines real-world views with simulated elements to provide real-time data overlays and guidance. | – Offers real-time scenario analysis – Enhances equipment interaction – Provides step-by-step guidance during training |

| Artificial Intelligence (AI) and Machine Learning | AI adapts training scenarios based on trainee performance, providing personalized learning experiences. | – Customizes difficulty levels – Tracks performance and suggests improvements – Simulates more realistic and dynamic scenarios |

| Advanced Data Analytics and Feedback Systems | Collects detailed performance data, offering real-time feedback on trainee actions and decisions. | – Provides in-depth performance evaluation – Identifies strengths and weaknesses – Enables targeted skill improvement |

| High-Fidelity 3D Simulation | Utilizes high-quality 3D modeling and graphics to replicate real offshore rigs and environments. | – Enhances visual realism – Offers detailed control systems and environment replication – Improves equipment familiarity |

| Multi-User Networked Simulators | Allows multiple trainees to interact in the same virtual environment, enabling team-based training. | – Fosters collaboration and teamwork – Enables role-specific training (e.g., rig operator, safety officer) – Encourages communication and coordination |

| Real-Time Environmental Simulation | Simulates dynamic environmental conditions like weather changes, sea states, and rig positioning. | – Prepares trainees for various operational conditions – Helps manage environmental risks – Ensures response accuracy in real-life scenarios |

| Cloud-Based Training Platforms | Facilitates remote access to simulator training from different locations, often in the cloud. | – Increases training flexibility – Enables training from any location – Reduces travel and logistical costs |

| Haptic Feedback and Motion Platforms | Integrates tactile feedback systems to simulate physical sensations when interacting with equipment. | – Enhances hands-on training experience – Provides realistic physical interaction with equipment – Improves motor skill development |

| Integration of IoT (Internet of Things) | Connects real-world equipment with the simulator to provide real-time data and monitoring. | – Simulates live rig data input – Enhances control system operation practice – Provides real-time scenario adjustments |

Summary

Oil rig simulators can help companies to improve safety, efficiency, and overall operational readiness. By providing realistic, cost-effective, and immersive training experiences, these simulators are revolutionizing the way personnel are prepared for the demanding and high-risk environment of offshore drilling. As technology continues to advance, oil rig simulators will become even more powerful, offering increasingly sophisticated and tailored training solutions for offshore drilling personnel.