How to Maintain Effective Well Control during Shale Gas Production

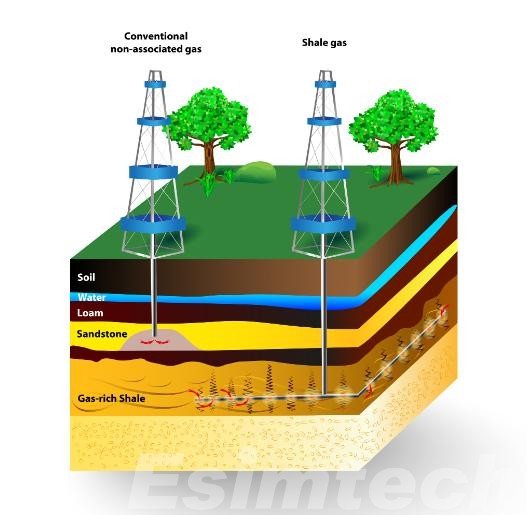

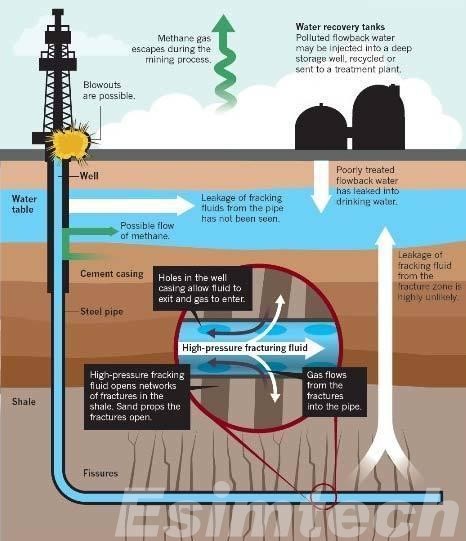

Shale gas production has unlocked previously inaccessible hydrocarbon reserves. However, the extraction of shale gas, primarily through hydraulic fracturing and horizontal drilling, presents unique challenges and maintaining effective well control is one of the main challenges. Ensuring well control is crucial to prevent blowouts, protect personnel and equipment, and safeguard the environment. This article explores the principles, challenges and best practices of well control during shale gas production.

Understanding Well Control in Shale Gas Operations

Well control refers to the techniques and equipment used to maintain pressure within a wellbore and prevent the uncontrolled flow of formation fluids to the surface. In shale gas operations, where horizontal wells and hydraulic fracturing are commonplace, the complexity of pressure regimes and fluid behavior makes well control particularly critical.

Shale formations are often characterized by:

- Low permeability

- High pore pressure gradients

- Unstable formations prone to collapse

These characteristics necessitate precise management of drilling mud weights, wellbore pressures, and casing programs to avoid influxes of gas or fluid.

Common Well Control Issues during Shale Gas Production

| Issue | Description | Contributing Factors |

| Kick (Formation Fluid Influx) | Uncontrolled entry of formation fluids into the wellbore | Underbalanced drilling, incorrect mud weight, poor pore pressure estimation |

| Wellbore Instability | Collapse or washout of the wellbore | Reactive shale, inappropriate drilling fluid, insufficient hole cleaning |

| Loss of Circulation | Drilling fluid lost into formation fractures or voids | Fractured zones, high mud weight, weak formations |

| Gas Migration | Movement of gas through cemented sections or casing | Poor cement bond, casing leaks, annular pressure |

| BOP Malfunction or Failure | Inability of blowout preventer to seal or control wellbore pressures | Poor maintenance, delayed testing, equipment wear |

| Poor Casing and Cementing Practices | Inadequate barriers between formations | Incomplete cement coverage, poor centralization, rushed operations |

| Human Error | Operator mistakes during drilling or completion | Inadequate training, poor communication, fatigue |

Key Technologies and Tools for Well Control During Shale Gas Production

Maintaining well control in shale gas production involves the integration of advanced technologies and precision tools. These systems are designed to monitor, regulate, and respond to complex pressure conditions that are characteristic of shale formations.

1. Blowout Preventer (BOP) Systems

Blowout Preventers are critical safety devices installed at the wellhead to seal the well in the event of a kick or blowout. In shale gas operations, BOPs must be designed to withstand high-pressure, high-temperature (HPHT) environments. They are equipped with multiple rams or annular preventers capable of closing off the wellbore quickly to prevent uncontrolled flow of gas to the surface. Regular pressure testing and maintenance of BOPs are mandatory to ensure reliability during drilling and completion.

2. Managed Pressure Drilling (MPD)

Managed Pressure Drilling is a closed-loop drilling method that allows operators to precisely control the annular pressure profile throughout the wellbore. In shale gas wells, where the pressure margin between pore and fracture gradients is narrow, MPD systems provide a dynamic way to adjust pressure in real time. This reduces the likelihood of kicks and minimizes the risk of formation breakdown or lost circulation.

3. Real-Time Monitoring and Control Systems

Modern shale operations rely heavily on digital technologies that provide continuous data on downhole conditions. Sensors placed along the drill string and wellbore measure variables such as pressure, temperature, flow rate, and gas composition. These data are analyzed in real time using advanced software platforms that can detect early signs of well control issues. Remote monitoring centers further enhance oversight by providing expert analysis and rapid decision-making support.

4. Advanced Drilling Fluids and Mud Systems

Drilling fluids used in shale gas wells are engineered to maintain wellbore stability, control pressure, and minimize formation damage. These fluids are designed with additives that enhance viscosity, reduce fluid loss, and provide wellbore strengthening. High-performance mud systems help maintain hydrostatic pressure and seal microfractures in shale formations, reducing the chance of kicks and differential sticking.

5. Casing and Cementing Technologies

Proper casing and cementing are foundational to long-term well control. In shale gas wells, cementing must provide a complete and durable seal across multiple pressure zones. Innovations such as expandable casing systems and self-healing cements are increasingly used to improve zonal isolation and reduce the risk of gas migration after completion.

6. Wellbore Strengthening Techniques

To prevent wellbore instability and minimize pressure-related risks, wellbore strengthening techniques are employed. These include the use of lost circulation materials (LCMs), stress cage techniques, and fracture sealing agents. These methods help increase the fracture gradient and enhance the structural integrity of the wellbore, especially in naturally fractured or pressure-sensitive shale formations.

7. Automated Kick Detection Systems

Automated kick detection systems are becoming a standard feature in shale gas drilling rigs. These systems integrate real-time data analytics and machine learning algorithms to identify abnormal flow patterns or pressure changes. Early detection is crucial for initiating timely shut-in procedures and deploying the BOP system effectively.

Operational Best Practices for Well Control during Shale Gas Production

Effective well control in shale gas production is not solely dependent on advanced technology and it also hinges on disciplined operational practices implemented consistently across the drilling, completion, and production phases. These best practices are grounded in industry experience, safety standards, and continuous improvement efforts aimed at reducing the risk of uncontrolled flow events.

1. Comprehensive Pre-Job Planning and Risk Assessment

Successful well control begins before the first drill bit touches the formation. Detailed pre-drill planning includes assessing formation pressures, designing a robust casing and cementing program, and choosing appropriate drilling fluids. In shale gas production, where formations can have unpredictable fracture networks and pressure regimes, anticipating risks through geological modeling and simulation is essential for safe operations.

2. Continuous Monitoring of Drilling Parameters

During drilling operations, real-time surveillance of key parameters—such as pit volume, pump pressure, flow rate, and mud returns—is critical. Any deviations from expected values may indicate a kick or loss event. Deploying automated monitoring systems and training personnel to interpret anomalies ensures that potential well control threats are identified and managed before escalation.

3. Maintenance of Drilling Fluid Properties

Drilling fluids serve as the primary barrier against influxes from the formation. Maintaining correct mud weight and rheological properties is particularly important in shale gas wells due to the narrow drilling margin between pore and fracture pressures. Frequent mud checks and adjustments ensure consistent hydrostatic pressure and reduce the risk of formation breakdown or influx.

4. Precision in Casing and Cementing Operations

Casing and cementing serve as key barriers to isolate high-pressure zones. Best practices include verifying centralizer placement, performing cement evaluation logs, and pressure testing the casing after setting. These steps ensure effective zonal isolation and long-term well integrity, which is crucial for preventing gas migration or annular pressure buildup post-completion.

5. Execution of Well Control Drills and Emergency Preparedness

Regular well control drills ensure that rig crews are proficient in recognizing kicks and executing shut-in procedures using blowout preventers. Emergency scenarios simulations help reinforce correct responses under pressure. Drills must reflect the complexities of shale gas operations, including horizontal sections and multi-well pad dynamics.

6. Pressure Management in Multi-Well Pads

Shale developments often involve simultaneous operations across multiple wells. Best practices include coordinating hydraulic fracturing and drilling schedules to avoid pressure interference. Monitoring nearby wells for signs of communication, such as pressure spikes or unexpected flow, helps preemptively manage inter-well interactions.

7. Post-Completion Surveillance and Integrity Testing

After a well is brought online, maintaining long-term control requires vigilant surveillance. Pressure sensors, gas detectors, and automated alarms support continuous monitoring. Periodic integrity tests of casing, tubing, and annular pressures confirm that containment systems are functioning properly and can detect slow leaks or compromised barriers.

8. Emphasis on Training and Safety Culture

A skilled workforce is the cornerstone of well control. Operators must invest in certified well control training, use of drilling and well control simulators, and sharing of operational lessons learned. A strong safety culture encourages proactive hazard identification, reporting of near-misses, and ongoing competency development across all operational levels.

Regulatory and Environmental Considerations for Well Control during Shale Gas Production

1. Regulatory Frameworks Governing Shale Gas Operations

Here is a chart summarizing regulatory frameworks governing shale gas production across key regions:

| Region/Country | Primary Regulatory Body | Key Regulations and Standards | Focus Areas |

| United States | - Environmental Protection Agency (EPA) - State Oil & Gas Commissions (e.g., Texas Railroad Commission) | - Clean Water Act (CWA) - Clean Air Act (CAA) - Safe Drinking Water Act (SDWA) - API Standards (e.g., API RP 53) | - Groundwater protection - BOP requirements - Methane emissions - Well integrity |

| Canada | - Canada Energy Regulator (CER) - Provincial regulators (e.g., Alberta Energy Regulator) | - Drilling and Production Regulations (SOR/2009-315) - Oil and Gas Conservation Rules (Alberta) | - Surface casing depth - Well control equipment - Environmental impact |

| European Union | - National regulators (e.g., UK’s North Sea Transition Authority) - EU Directives | - EU Water Framework Directive - EU Mining Waste Directive - National BOP and casing regulations | - Water and waste management - Public disclosure - Fracturing fluid control |

| China | - Ministry of Natural Resources - Ministry of Ecology and Environment | - Shale Gas Development Plan - Environmental Protection Law - National BOP standards | - Air and water pollution - Drilling permits - Seismic risk control |

| Australia | - State-based regulators (e.g., Queensland Department of Resources) | - Petroleum and Gas (Production and Safety) Act - Code of Practice for Hydraulic Fracturing | - Aquifer protection - Safety management plans - Chemical disclosure |

2. Environmental Protection and Risk Mitigation

Shale gas wells often intersect aquifers and environmentally sensitive zones. Well control failures in these areas can lead to contamination of groundwater resources, soil, and surface waters. As such, environmental protection is a central concern in well control planning. Regulatory agencies often mandate multiple casing strings with cemented sections to provide barriers between the wellbore and freshwater zones.

Operators must also ensure that any potential release of hydrocarbons, drilling fluids, or produced water is contained and managed through appropriate surface infrastructure. Secondary containment systems, spill response plans, and zero-discharge policies are commonly enforced in shale-rich regions to reduce environmental exposure.

3. Blowout Preventer Testing and Certification

Regulatory agencies require routine testing and certification of BOP systems to ensure their functionality under pressure. These tests must be documented and conducted in accordance with approved schedules, often before drilling out casing shoes and at defined intervals during the operation. In high-risk formations like shale, BOPs must meet stringent reliability standards and incorporate redundant control systems, including remote and automated shut-in capabilities.

4. Emissions and Air Quality Management

Well control events such as blowouts or flaring can result in significant emissions of volatile organic compounds and greenhouse gases. Regulatory bodies impose limits on emissions from well sites, with specific focus on methane leakage during both drilling and production. As a result, operators must implement leak detection and repair (LDAR) programs, use vapor recovery units, and adopt best practices to minimize emissions during well control activities.

5. Emergency Response and Reporting Protocols

In the event of a well control incident, regulations require prompt notification of local authorities and environmental agencies. Operators must have pre-approved emergency response plans that outline containment procedures, evacuation protocols, and environmental remediation strategies. Drills and tabletop exercises are often mandated to ensure personnel readiness and inter-agency coordination in the event of an actual emergency.

6. Public and Stakeholder Engagement

The environmental risks associated with well control in shale gas production often draw public attention. Transparency in operations, including community engagement and disclosure of well control practices, plays a vital role in building public trust. Many jurisdictions now require disclosure of hydraulic fracturing chemicals, baseline water testing results, and incident reporting to public databases.

Final Thoughts

Effective well control during shale gas production is a complex but essential aspect of safe and efficient operations. With the integration of advanced drilling technologies, real-time monitoring, and skilled personnel, operators can manage the unique risks associated with shale formations.