How to Optimize Top Drive Systems

Top drive systems are the foundation of modern rotary drilling, providing improved control, greater flexibility and more safety when compared with traditional rotary table systems. In the current oil and gas industry, which moves into more challenging environments, including high-temperature and high-pressure (HPHT) wells, offshore ultra-deepwater fields, etc, the ability to optimize the top drive system is crucial to maximize performance, reducing non-productive time and ensuring operational integrity.

The Role of Top Drive Systems in Drilling

Top drives are a mechanical device hung from the mast or derrick in a drilling machine capable of turning the drill string, allowing vertical movement. As opposed to rotary tables, which require manual pipe handling as well as the Kelly system, top drives speed up operations through continuous rotation and automated pipe connections, thus increasing the speed and security.

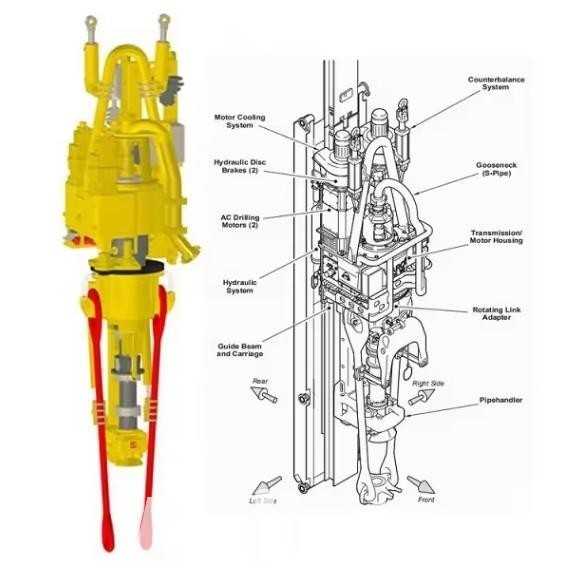

Key Components of a Top Drive System

| Component | Description |

| Electric/Hydraulic Motor | It provides the power rotation needed to rotate on the drilling string. |

| Gearbox | Reduces speed and boosts torque output of the motor. |

| Main Shaft | Transmits the rotation of the gearbox and motor to the drill string. |

| Swivel | Fluid circulation is allowed during the time that the drill string is turning. |

| Pipe Handler (Link Tilt & Spinner) | Helps with making and breaking connections to drill pipe effectively and safely. |

| Torque Arrestor | The top drive is prevented from spinning independently of the structure of the mast. |

| Guide Track System | The guideline guides the vertical movement from the top drive on the mast or derrick. |

| Control System | It includes hardware and software to control motors as well as safety functions and automation. |

| Cooling System | The motor is controlled by the thermostat and electronics to ensure that they are not overheat. |

| Backup Clamp/Elevator | The drill string is supported and offers additional handling capabilities. |

Key Strategies for Optimizing Top Drive Systems

1. Advanced Motor Technologies

A single of the most efficient ways to improve a high-performance drive system is through the utilization using high-efficiency technology for motors. Electric motors, especially when used in conjunction with Variable Frequency Drives (VFDs) provide precise control of speed and torque that allows an easier and more flexible operation in various downhole conditions. These systems not only decrease the energy use but also increase performance, particularly in complex operations like directional drilling or reaming.

Hydraulic motors are still being used, are slowly being replaced, or are integrated with electric systems because of their effectiveness and control. In switching to electric high-efficiency drives, operators can cut operating costs and reduce the environmental impact of their drilling activities.

2. Implementing Predictive Maintenance and Real-Time Monitoring

In order to reduce the amount of time spent on non-productive tasks and avoid unexpected failures, top drive systems should be equipped with automated maintenance instruments. Through the integration of sensors that track temperatures, vibrations, torque, as well as loads, the operators can monitor the health of components in real-time. The information gathered is then analyzed by using diagnostic software and machine-learning models that forecast wear patterns and the likelihood of faults.

This method allows maintenance to be carried out in a proactive manner instead of reacting, which means longer equipment lifespan, fewer breakdowns, and more stable drilling processes.

3. Improving Safety and Reducing Manual Intervention

Safety is a primary concern during drilling, and maximizing the top drive system could significantly improve worker safety. The integration of automated pipe handling systems--including remote-controlled spinners, link tilt tools, and torque control mechanisms--minimizes manual intervention during make-up and break-out operations.

Furthermore, anti-collision devices and built-in emergency stop functions offer additional layers of security in tripping-related activities. These safety measures not only ensure the safety of personnel, but also to avoid costly damage to equipment and downtime.

4. Streamlining Design

Top drive technology is constructed with modularity and compactness at the back of their minds. Making use of high-strength, lightweight materials like advanced carbon fiber composites can reduce the weight of the device, which is particularly advantageous for mobile and offshore drilling rigs.

Modular components allow you to install, transport, and manage the equipment, decreasing downtime and increasing flexibility to use it in various operational setups or rigs.

5. Integrating with Digital Drilling Platforms

Digital transformation is changing the drilling industry. The integration of an advanced drive platform onto an overall digital platform improves the visibility of operations and controls. With remote monitoring interfaces and central control panels, engineers can alter parameters like RPM as well as torque and pressure in real-time.

This integration allows closed-loop drilling automation, in which it is possible for the upper drive system to reacts automatically to data from the downhole by adjusting its performance in order to maximize the rate of penetration (ROP) to limit damage to the formation and ensure the integrity of the borehole.

6. Ensuring Compatibility with Advanced Drilling Techniques

When drilling techniques advanced, such as Managed Pressure Drilling (MPD) and Extended Reach Drilling (ERD), top drive systems need to be able to adapt. Optimizing the system to take advantage of these new techniques requires enhancing the torque capacity, extending the length of travel vertically and allowing the control of rotational and pressure.

In ensuring that the top technology drives work with these methods, operators are able to tackle more difficult wells and boost the effectiveness of each drilling operation.

How Simulation Technology is Used for Optimizing Top Drive Systems

Oil and gas simulation tools adopt the latest advanced software and digital models, and engineers can analyse the design, test, and refine the design and operation of the top drive system prior to implementing it in the field. This ability to predict and iterate is not just a way to reduce risk, but also improves performance, security, and reliability.

Virtual Prototyping and Design Optimization

Before a top drive is built or modified, the simulation process allows engineers to design a digital version of the whole assembly comprising gearboxes, motors, load paths, as well as control systems. By using FEA as well as multi-body dynamic simulation, engineers can determine weak points in the structure, optimizethe utilization of materials, and analyze the performance of the system under tension, stress ,and dynamic loading. This process enables cost-effective design adjustments that improve durability, torque transmission, and weight distribution--without the need for physical trial-and-error.

Control System Validation and Performance Tuning

Top drive systems depend extensively on algorithms for control to regulate motor speed and torque, braking, and also synchronization with other equipment. Simulation technology is able to replicate drill scenarios from the real world in an environment that is virtual environment, which allows engineers to evaluate the response of control systems to changes in load and conditions in the downhole, as well as unexpected events such as pipe sticking and sudden surges in pressure.

By re-creating these scenarios, engineers can tweak the timing of the response and feedback loops as well as the security procedures of control software. This is increasing the stability and precision of the top drive's performance before deployment.

Predictive Maintenance Modeling

Simulation is also a key component in the creation of strategies for predictive maintenance by analyzing wear and degradation pattern over the course of time. By combining historical data with the simulation of stress and load cycles digital twin models are able to determine when components like gearboxes, bearings, and drive shafts are more likely to fail. This information allows maintenance personnel to plan repairs or replacements prior to breakdowns, thus reducing non-productive times and increasing the efficiency of operations.

Training and Skill Development

Simulation technology is also extremely useful to train operators. Top drive simulators that are high-fidelity simulate the behaviour of the system in various scenarios, such as normal drilling, tripping, managing pipe connections or in emergency situations. This lets rig workers learn hands-on in a secure virtual setting, increasing their ability to perform and decreasing the chance of human error in actual operation.

Integration Testing using Rig Systems

Top drive systems work closely with other drilling elements such as draw works, mud pumps as well control systems. By using system-level simulations, engineers can determine the way that top drive systems integrate into the larger rig ecosystem. This is especially helpful to validate digital interlocks, making sure that systems are in safe communication and identifying possible conflicting processes before drilling starts.

Future Trends in Optimizing Top Drive Systems

Future of top drive system optimization lies in the intersection of mechanical innovation, digital transformation and sustainability.

- Electrification and Next-Generation Motor Technologies

One of the most important changes is the shift towards full electrification. The future leading drive technology is anticipated to use high-torque, efficient electric motors that will decrease the dependence on hydraulic systems. Electric drives, when paired with cutting-edge inverters and control techniques, will provide better efficiency in energy consumption, more efficient control of torque, and lower maintenance needs. Furthermore, the incorporation of regenerative energy systems - capable of collecting energy during tripping operations- will help to create more environmentally sustainable drilling methods.

- Digital Twin and AI-Powered Predictive Maintenance

Digital twins, virtual copies of top drive systems with physical components, are being developed as a useful instrument for monitoring in real-time, optimization, and diagnostics. When used in conjunction with Artificial Intelligence (AI), the systems are not just able to predict failures in equipment, but can also recommend optimal operating parameters, based on historical and real-time information. This will enable maintenance based on condition, which will reduce the time between breakdowns and prolong the life of the equipment.

- Enhanced Automation and Remote Operation

As the industry progresses toward fully automated drilling equipment, the future top drive systems will play an integral part in ensuring hands-free pipe handling and fast drilling. A better integration with the rig automation platforms will allow remote control of the top drive functions, which will reduce human involvement in risky zones. Innovative safety locks with self-learning algorithms as well as auto-calibration capabilities will further improve the system's autonomy and reliability.

- Modular and Lightweight Design for Rig Flexibility

Future designs will emphasize modularity and compactness in order to increase the efficiency of installation and make it compatible with different types of oil rigs, such as mobile rigs, offshore platforms, and drilling units that are unmanned. The use of lightweight high-strength composite materials will decrease the overall weight while ensuring durability. This will not only decrease costs for transportation and setting up rigs, but will also increase the stability of the rig and efficiency in energy use.

- Cybersecurity and System Resilience

As top drives become increasingly digital and connected, security will be an essential aspect of optimization. Future systems will be equipped with security-grade communications protocols, multi-layered defense strategies, and tools for detecting anomalies to guard against data breaches as well as malicious interference. The ability to ensure system resilience is essential to maintain the safety and continuity of operations for digitally connected rigs.

- Sustainability and Environmental Considerations

Top drive optimization will show the growing importance of the industry at environmental sustainability. Energy-efficient systems powered by electrified technology will lower the amount of fuel used and emissions. In addition, sustainable materials as well as noise reduction techniques and environmentally-friendly hydraulic fluids (where they are used) are expected to be standard in top drives of the future.

Summary

Optimizing top drive systems is a crucial aspect for modern drilling operations. Through enhancing power efficiency, safety, digital integration, and mechanical performance, operators can achieve higher efficiency, better wellbore quality, and safer working environments. The oil and gas sector continues to advance, the top drive systems will be the center of advancement and value creation throughout the drilling lifecycle.