Step-by-Step Guide: Training with an Oil and Gas Drilling Rig Simulator

Oil and gas industry operation needs hands-on experience, but real-world drilling is risky and costly. That is where the drilling rig simulator comes in: a safe, controlled virtual environment that replicates actual rig operations, which allows trainees to develop practical skills, respond to emergencies, and gain confidence before going to work on a real oil rig. This guide will walk you through the benefits and best practices for getting the most out of an oil drilling rig simulator.

What is a Drilling Rig Simulator and What’s the Role?

The drilling rig simulator is an advanced training system that simulates real-life conditions for oil and gas well drilling in a virtual environment. It provides realistic hands-on experience, different from instruction in a classroom atmosphere, where trainees can work with controls, instruments, and procedures as they would on an actual rig. In this safe and controlled environment, trainees practice to develop confidence and learn the operational basics without risks associated with live drilling.

The main roles and benefits of a drilling rig simulator include:

- Skill Development: Trainees can learn the management of drilling processes, complex machinery operation, and overall critical systems monitoring effectively.

- Safety Training: Simulators allow users to practice emergency scenarios, such as equipment failures or blowouts, in a zero-risk environment.

- Cost Efficiency: Training on a simulator reduces wear and tear on actual rigs and minimizes production downtime.

- Performance Assessment: Getting detailed feedback and analytics supports progress monitoring at individual levels.

In real life, a simulator for drilling rigs acts as the connecting link between theoretical knowledge and practice. It enables operators to practice complex tasks, enhance their decision-making in time-sensitive scenarios, and gather practical experience before being sent to work on an actual oil rig. For modern oil and gas companies, such simulators guarantee a safer and more competent workforce by enhancing general operational efficiency and reducing training costs.

Key Benefits of Using an Oil Rig Simulator for Training

Training on an oil rig simulator is so much more than just familiarizing oneself with controls; it completely changes the way operators learn and prepares them for real-world drilling challenges. In contrast to traditional techniques, simulator-based training provides immersive and fully interactive experiences that accelerate learning while maintaining safety and efficiency.

Some of the major advantages:

- Hands-on practice in a no-risk environment: The trainees can try to execute complicated drilling procedures and the operation of equipment without risking accidents or environmental hazards.

- Improved Operational Readiness: Repeated practice on an oil rig simulator builds confidence and prepares the operators for routine and unexpected situations that might arise on actual rigs.

- Customized Scenario Training: Simulators can simulate various conditions, such as offshore operation, high pressure well conditions, or emergency scenarios. This familiarizes operators with operational modes they may not experience often.

- Improved Team Coordination: Most simulators offer multi-user session capabilities, allowing crews to practice communication, decision-making, and collaborative problem-solving in controlled environments.

- Data-Driven Feedback: Through performance metrics from simulator sessions, instructors get objective insights into skill levels, enabling them to identify gaps and tailor programs accordingly.

In sum, the use of an oil rig simulator goes beyond basic training; it instills practical skills in operators, enhances safety awareness, and builds team efficiency. A drilling organization can reduce operational risk, enhance the competence of the workforce, and consequently ensure more reliable and productive drilling operations by introducing learning on the simulator.

Steps of Training with an Oil and Gas Drilling Rig Simulator

Training on an oil and gas drilling rig simulator has a step-by-step approach to building operator competence in an orderly manner. The approach aims at ensuring that the trainees not only acquire theoretical understanding but also hands-on experience with confidence levels before engaging in practical field operations. A simulator allows trainees to repeat tasks, make adjustments, and learn from mistakes without risk.

Key steps in the training process include:

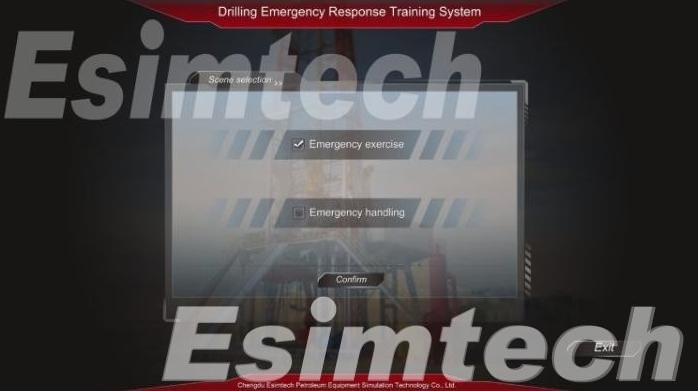

First Step: Orientation & Interface Familiarization

They start by familiarizing themselves with the interface of the simulator: learning the control panels, monitoring instruments, and safety alerts. The more familiar someone is with the system, the better their operation of it will be and the quicker they can act in any simulated scenario.

Step 2: Practicing Basic Drilling Operations

Following orientation, trainees begin with basic drilling operations: control of the drill bit, pressure, and torque, and fluid systems monitoring. In this way, the operator, using the drilling rig simulator, can practice repetitive tasks until consistent accuracy is achieved, which will then translate to improved skills in the field.

Step 3: Advanced Drilling Scenarios

When the basics have been mastered, trainees move on to more complex operations: multi-stage drilling, offshore challenges, or high-pressure wells. The simulator can simulate all sorts of different conditions, everything from equipment failure to environmental perils, and let the trainees try their hand at solving problems under pressure.

Step 4: Emergency and Safety Drills

A significant benefit of a drilling rig simulator is the safe rehearsal of emergency scenarios, such as blowouts, equipment failure, and evacuation procedures. These frequent practices ensure that operators will be quick to act with efficiency in real-life emergencies.

Step 5: Performance Monitoring and Feedback

Most of the simulators will also log performance based on accuracy, response time, and procedure adherence, among other metrics. Trainers will use this information to identify areas for improvement and create specific further sessions to ensure continuous training.

In this way, the trainees progress smoothly from an understanding of basic operations to the confident handling of difficult, high-consequence situations. Structured learning, repeated practice, and data-driven feedback are combined in one tool: the oil rig simulator is indispensable in training competent and safety-conscious operators in the oil and gas industry.

Tips for Maximizing Your Oil Rig Simulator Training

Maximizing the benefits of an oil rig simulator isn’t just about putting in hours; it’s about practiced engagement and strategic exercise of skills. The following guidelines will assist in making sure simulator training develops competence in practice.

- Develop a Consistent Training Schedule: Confidence comes with repetition and skills are developed and reinforced with practice. Regular use of the oil rig simulator ensures that operators commit critical procedures to memory and perform tasks under pressure with precision.

- Create Conditions Similar to Those in the Field: Create situations involving offshore drilling, high-pressure wells, or equipment failure. The more lifelike the training, the more equipped trainees will be to handle the rig’s unpredictable challenges.

- Train as a Team: Numerous drilling operations consist of several operators. Utilize multi-user simulations for practicing communication, coordination, and decision-making in high-pressure situations. This strengthens team efficacy in high-pressure environments.

- Utilize Performance Feedback: Evaluate response time, accuracy, and compliance with procedures. Feedback reports assist trainees in recognizing shortcomings, thereby helping them effectively target areas of improvement.

- Combine Theory with Practice: Pair simulator activities with classes on the mechanics of the equipment, drilling fundamentals, and safety procedures. This enhances the grasp of the concepts and ensures the skills will be used properly in actual operations.

By following these tips, trainees can fully harness the potential of an oil rig simulator, improving safety, operational efficiency, and overall competence. A structured, intentional approach ensures that simulator training is not just practice—but a stepping stone to real-world expertise.

Conclusion: Why Oil and Gas Companies Invest in Drilling Rig Simulators

Investing in drilling rig simulators is no longer optional for forward-thinking oil and gas companies—it’s a strategic necessity. These simulators enhance safety, improve skill acquisition, reduce operational costs, and provide measurable training outcomes. They empower new and experienced operators alike to handle complex drilling scenarios with confidence, ultimately contributing to higher efficiency, fewer accidents, and stronger operational performance.

For any organization looking to maintain a competitive edge in the oil and gas industry, adopting oil rig simulators for workforce training is an investment that delivers long-term benefits both on and off the rig.