Top Drive Systems in Modern Oilfields: Efficiency, Safety and Technology

gas industry, transforming the process of drilling via increased efficiency, safety, and technological performance. However, the top potential of a top drive drilling rig can only be achieved by employing a highly trained personnel. This is where the paramount role of top drive simulation becomes evident. Being an expert manufacturer of top drive simulator systems, our emphasis is to close the gap between cutting-edge hardware and human know-how so that the advantages of top drive drilling are experienced safely and efficiently on every well.

Top Drive Drilling and Its Role in Oilfields

With top drive drilling, the operator can control the torque and rotate the drill string while allowing for especially intricate well paths. Attaching top drive systems on top drive drilling rigs enables the operator to drill faster and deeper while completing complex well paths that cannot be achieved with the rotary table penetration methods.

These advanced systems cannot simply be mastered with theoretical knowledge, as operators need to possess the ability to control the rig and geo-pressures while managing other factors and being responsive under well pressures. This is when a top drive simulator is important. These simulators securely replicate actual drilling and allow operators to refine decision-making and gain the muscle memory required in operating a real rig.

Thus, the field teams can operate safely and efficiently, as top drive systems and top drive simulators have high customer satisfaction.

Efficiency Benefits of Using a Top Drive Drilling Rig

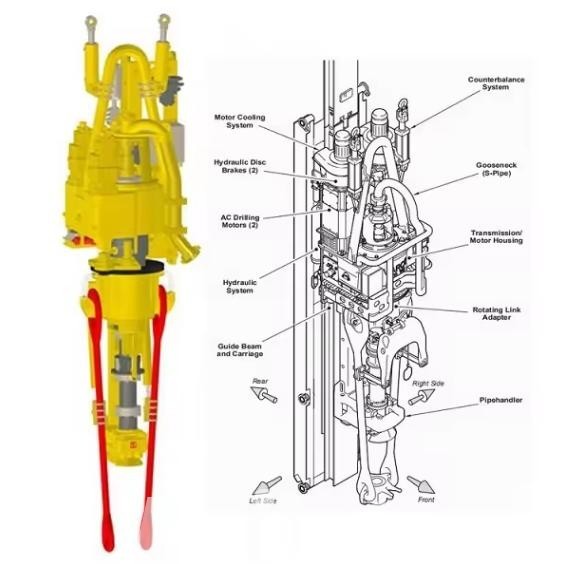

Adding a top drive system (TDS) to a modern drilling rig is one of the most pivotal improvements of modern drilling technology. This change makes the operation more efficient than using the rotary table systems with a top drive. These TDS systems can now perform drilling with both rotation and circulation simultaneously and thus change the drilling operation. The benefits can now be analysed across several dimensions of the operation.

- To begin with, a top drive system significantly improves connection time. Instead of single joints, TDS systems handle stands of drill pipes. This reduces the connections needed by 2/3rds. This system is much more efficient than the rest because there is a reduced risk for the drill to become stuck on the lower section.

- Moreover, top drive systems change the way that engineers think about precision, efficiency and flexibility. The TDS system is able to complete circulation while tripping, greatly increasing the rates of hole cleaning. Engineers can also ensure circulation, that is, active circulation from the bottom to the top of the system to the well and down for wellbore cleaning to avoid cuttings that stick to the wellbore. Engagement of the system at optimal drilling speeds and rock changes ensures that there is maximum penetration and a low risk of equipment breakdown.

- Third, we know that top drive systems now readily ‘talk’ to automated drilling controllers. That connection allows adjusting drilling parameters on the fly, automation of pressure control, and constant data stream evaluation. Automated response to downhole measurements ensures optimal operational efficiency, minimizing mechanical specific energy (MSE) and elevating drilling performance.

These ‘Plus’ efficiencies normally translate as time savings of the order of 15-25% on drilling, lower total drill time and cost, and better integrated wellbore for subsequent completion operations, which translates to FRE (Faster, Reliable, and more economical wells). Top drive systems make the economic case for drilling as a vital component of any 21st-century cost-controlled top drive systems.

Enhancing Safety with Top Drive Technology

Using top drives for drilling operations still increases safety standards due to the fact that these systems automate processes that are deemed high-risk mechanized. While exposures to uncertain hazards are lessened, overall remote controlling of the drill systems is still enhanced.

- Safety incorporated advancements are far more beneficial than other systems. Having the red zone manually connected, for example, rotating systems at one time needed roughnecks, who worked near the tables, that spun chains and other devices. Top-drive systems completely remove the risk of perilous areas and provide mechanisation of breakout and pipe drill stands. Decreased risk of strikes and hand injuries are top benefits too.

- With the use of top-drive systems, the ability for any well control safety is achieved. Wellbore shakers become much easier to use and are much more stable. The ability to circulate and trip at the same time is of great importance to all operators. There are highly integrated safety systems, i.e. blowout control using auto darts and remote control, on the well on top of all other systems.

- Protection against loss of well control is possible due to the systems still breaking down eases on the wellbore. The system handles itself and all decided upon equipment. There is real-time tracking of the other equipment that gets remotely monitored. The system overall works towards preventing all other situations that can spin out of control.

The top drive is made to be efficient with its integrated safety features, but also designed to be as safe as possible for the personnel, equipment, and the drill site, which all need protection during the drilling processes.

Training and Skill Development with a Top Drive Simulator

Top drive simulators allow users to practise almost real-world drilling functions in a prepared environment. Users can learn how to control various operations such as torque, control pipes, and manage well trajectories. Repeated practice in a simulated environment hones muscle movements and the necessary skills before attempting to operate a real top drive drill.

- Risk-free Evolution of Real-life Situation

Simulators provide operators the opportunity to practise in time pressure situations, pipe obstacles, unstructured well behaviour, and other scenarios without any risk of injury or damage to the equipment. This practice builds confidence and teaches operators how to promptly and properly react to real-life drilling conditions.

- Collaborative Strategies and Awareness

In addition to technical skills, top drive simulators reinforce collaboration and critical thinking skills. Operators learn to work together during a drill, improving timeliness, communication, and awareness of the other operators. This enhances the safety and efficiency of drilling operations.

- Cost and Time Effectiveness

The time spent during practice on the drill simulator instead of on the rig helps avoid long installations and adjustment periods for the drill, thereby reducing operational expenses and saving time. At the same time, they can go through the same learning modules as the newcomers.

The incorporation of high-fidelity simulation tools in training modules equips them with skills of technical competence along with the confidence and coordination needed for the success of actual drilling operations in oil fields.

In a Word

In the latest oilfield operations, skilled operators combined with advanced top drive systems ensure operational safety and efficiency. Advanced oil and gas top drive simulators work easily with operators’ modern 3D training systems. One of the key aims of the simulator is to replicate field experience in the oil and gas sector. With simulator training, firms operate within the defined safety parameters, improve operator skills, and reduce risks associated with top drive drill rigs. As a top drive simulator manufacturer, we enable companies to overcome the safety challenges associated with top drive drilling systems. You can contact us for any of your oil field drive simulation training systems.