Well Control During Workover and Well Intervention

Operations involving workover and well intervention help aid the oil and gas industry by helping sustain, fix, and improve wells. Optimizing well productivity, preventing damage, and maintaining the safety of people and tools involved requires the use of a hierarchy of approaches and technologies. A major element in both workover and intervention activities is well control, which is the governing of the pressure and flow in the well to avert blowouts and other dangerous situations. These well control procedures help to keep the personnel safe, the environment protected, and the well intact. This article discusses the most efficient methods, tools, and actions for well control during workover and well intervention.

Understanding Well Control in Workover and Well Intervention

Preventing the well from experiencing an uncontrolled release of formation fluids is termed well control in the oil and gas sector. Workover and intervention control is a function of multiple variables, controls and parameters including, but not limited to, the complexity of the well, the fluids in the well and the pressure of the reservoir.

Both Workover and well intervention have the following processes:

- Well Preparation: Understanding well conditions and ensuring all safety protocols have been satisfied.

- Pressure Management: Understanding pressure ranges to prevent kick or outflux.

- Monitoring and Control: Acts of the well and operational safety are managed in real-time, and reactions to changes in pressure are immediate.

Key Procedures in Well Control During Workover and Well Intervention

Key procedures involved in well control during workover and well intervention focus on pressure management, well monitoring, and emergency response strategies.

1. Well Preparation and Pressure Containment

The first element in the assurance of well control during workover and intervention is satisfactory well preparation. Operators must have definite knowledge of the well condition, such as the formation pressure, and the type of fluids that are present, prior to any work activities. Preparing the well includes confirming that all well control tools are present and operational, which include the Blowout Preventer (BOP), kill lines, choke manifolds, and pressure monitoring devices.

To stop the formation fluids from moving freely to the surface, the first step of the operation should always incorporate pressure containment. The first line of defense is the BOP. A BOP is specialized equipment that can close the borehole and separate the well from the surface equipment during a pressure increase. There is also a secondary system made up of choke manifolds and kill lines, which interface with the well fluids to assist with managing the pressure control in the well.

If the well is sufficiently prepared, and all pressure containment systems are in place, operators can almost completely mitigate the risk of an uncontrolled formation fluid release.

2. Kick Detection and Monitoring

A critical element of ongoing well control during a workover or an intervention is the ability to identify and mitigate kicks. A kick is the sudden ingress of formation fluids into the wellbore, usually as a result of a pressure differential. If this is not controlled, kicks can lead to a blowout that can irreparably damage the well and the equipment, and can even result in the loss of life.

The beginning of the escalation of pressure issues can start as early as the start of the problem, with the very first indications of pressure issues. In order to address the issues, users depend on systems and sensors that allow them to keep track of the pressure in real time. In order to recognize unusual pressure changes, we use pressure sensors at the head of the well along with the data from the mud logging and flow rate monitors.

Circulating out the formation fluid is a part of well control procedures that initiated to remove a kick from the well. It is imperative that users learn the signs of a kick in order to avoid further difficulties with the intervention at a later time.

3. Well Killing Techniques

The detection of a kick activates one of the most essential procedures for controlling a well: the conducting of well killing operations. The killing of the well is defined as the neutralization of the inflow of formation fluids, as well as the return of the wellbore to a stablized condition.

The killing of a well can be carried out using one of the two main approaches, that being dynamic kill and static kill. In a dynamic kill, the well is in circulation using a heavy drilling fluid while circulation is being maintained in the wellbore. The formation fluids in the well are replaced with a heavier fluid to balance the pressure in the well, which is a primary objective. This destabilization of the pressure is an overall positive thing and the method is a standard one for wells where the circulation of the well is possible.

In a static kill, the well gets sealed and a heavy fluid gets pumped into the wellbore and then is not circulated. This is done when there is no circulation, or when it is circulating then it gets stopped. The working static pressure within the heavy column then gets the job done and influx of formation fluids gets stopped aka well gets killed.

Safety of the operation relies on accurate calculations of fluid densities, flow rates, and well pressure in both methods. The key to a successful well kill is maintaining a pressure balance on the well that keeps the well under control and prevents any further influx.

4. Well Control Equipment Testing and Maintenance

Completing proper maintenance and testing of well control equipment is crucial for every well control operation. For every workover or intervention, operators have to make sure that no critical well control systems like the BOP, kill lines, and choke manifolds are out of service.

In order to ensure the capability of the well control gear, Pressure tesing must be carried out. This means testing the BOP along with the other pressure containment systems to make certain they are able to endure the operational pressures. Performing regular maintenance on these systems is equally as critical as the others since the potential for catastrophic equipment failures exists if control of the well is lost.

Well control equipment requires routine inspections along with ongoing preventative maintenance to include seal replacements, recalibriations, and other routine well control equipment maintenance.

5. Emergency Response Procedures

Even with the preparation and planning, unexpected events can and will happen when conducting workover and well intervention operations. An all inclusive and well constructed set of emergency response plans is the key to mitigating any well control problems that may come up.

These emergency response plans need to include detailed actions steps for kick events, blowouts, and other emergency situations that require the rapid engagement of well control equipment such as the BOP and rapid personnel evacuation steps. Supervisors on the well site along with well control specialists must be trained, knowledgeable, and competent to perform the emergency procedures as necessary.

For Emergency Response Training, such as those offered by the International Well Control Forum (IWCF), provide all personnel training for emergency situations. Conducting emergency training exercises and simulations ensures all individuals on site determine how best to respond to any emergency.

6. Post-Operation Monitoring and Evaluation

After the conclusion of the workover or well intervention, it is necessary to complete a comprehensive post-operation review. This includes an examination of the well control for the procedure and a determination of the actions taken and their success. Operators need to look at control of any well issues that may have occurred, such as kicks or pressure differentials, and how control of those issues will be managed in the next procedure.

For post-operation control, it is necessary to determine that the well is stable after the intervention. This includes confirmation that all well control apparatus remains operational, and no new pressure differentials have occurred. Active closed monitoring control systems should be maintained to provide oversight of the well after the operation and ensure that any new control issues will be managed without delay.

Key Safety Measures for Well Control during Workover and Well Intervention Operations

Comprehensive Training and Certification

Probably the most important safety measure for workover and well intervention operations is the training and certification of personnel. Well control is of the greatest risk, and operators, engineers, and field personnel need to be fully knowledgeable of the control of well associated risks and the processes involved for working with and control of that risk.

Training programs like the ones developed for the International Well Control Forum (IWCF) and International Association of Drilling Contractors (IADC) will assist personnel to identify control well problems and understand the necessary steps to accomplish control coordination. Certification is a key component that personnel is expected to understand control of a well, the theory of control, and the procedural issues of well control relating to well control pressure management and prevention of blowout(s).

Subscribe to the presiding control of a well organization and members need to be involved in a working and well control organization in the rights of control of the well, to maintain training is sustained on a regular basis. Well control training should include simulated high-pressure environments in which well control training can assist to manage the organization.

Pre-Operation Risk Assessment

A complete risk assessment should be done before starting any well intervention operation. This should assist in determining the risks presented by the well’s pressure, fluids, and depth. This helps prepare the intervention team so as to be able to mitigate risks.

Also, there should be some mud monitoring as well as some calculations of fluid weight to ascertain whether the mud system is able to accommodate influxes of formation fluids. If mud weight adjustments are necessary, they should be done before operating to ensure adequate pressure control.

Continuous Monitoring and Real-Time Data Collection

During the operation, well conditions should be continuously monitored to identify any early signs of pressure imbalances or other well control issues. Real-time data collection systems should be able to keep track of pressure, flow rate, and weight of the mud so as to assist operators in monitoring the well conditions.

Thanks to real-time monitoring technology, the team can spot kick signals, when formation fluids are beginning to enter the wellbore, a scenario that could potentially lead to a blowout if left unchecked—early. Automated systems have the ability to let the operators know ahead of time that a potentially dangerous situation is developing, giving them time to intervene and correct the problem before it gets worse.

In addition to monitoring pressure, well control also should measure temperature and changes in volume in the wellbore. Knowing these parameters will allow the team to quickly gauge the state of the well and to keep the pressure control in the state of fluid equilibrium.

Technological Innovations in Well Control during Workover and Well Intervention

In recent years, several innovative technologies have been developed to enhance the ability to detect, prevent, and manage well control problems that arise during workover and intervention operations.

- Automated Well Control Systems

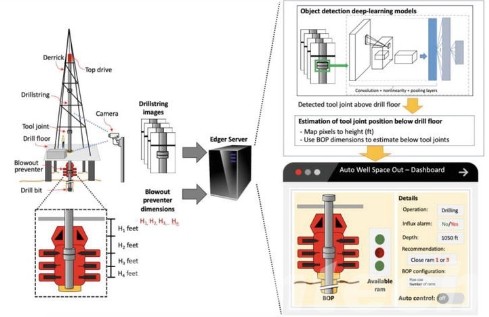

Another major creative advancement in technology is in the automated control of wells systems, which utilize artificial intelligence (AI) and machine learning (ML) to track and control the well’s pressure. These systems utilize sophisticated algorithms that affect real-time data from the well to make automatic changes to the control of pressure equipment which includes blowout preventers (BOPs), choke manifolds, and kill lines.

Automated well control systems have the ability to respond to pressure changes more quickly and more accurately than human operators, reducing the potential for error and increasing operational safety. Automated well control systems can even respond to kicks for some time without the need for human intervention, thus gaining control over the well more quickly.

- Advanced Blowout Preventer (BOP) Technology

Blowout preventers are important pieces of safety equipment that ever the wellbore and stop the unrestricted flow of fluid and other formation components when there is drilling, workover, or intervention. The most recent innovations in BOP technology have improved reliability and performance of BOPs.

New advanced sealing mechanisms, such as annular BOPs and shear rams that can cut the drill pipe when the pipe is stuck, are some of the new features in BOPs. These BOPs are also able to provide safety at even higher pressures at deeper wells. BOP monitoring also allows for more frequent assessment of critical indicators, such as seal integrity, ram position, and fluid flow, enabling operators to anticipate problems.

- Advanced Well Control Fluids

The advanced well control fluids developed help with workover and intervention operations. Today’s drilling fluids, specifically synthetic-based muds (SBMs) and high-density brines, serve to control formation pressure, control fluid loss, and control wellbore instability.

These fluids have an advanced rheological property which means they flow better and can hold a more stable pressure profile in the well. Moreover, microcontrolled and polymerized fluids further improve flow and sealing mechanisms while decreasing formation damage risk in well control.

Smart fluids—fluids with sensors or additives that adjust to certain well conditions—are the most promising. These fluids control downhole conditions, or temperatures and pressures, achieving even more control over the well.

- Kick Detection and Early Warning Systems

Perhaps the most important part of controlling the well is the kick detection, due to the possibility of formation fluid inflow. Traditionally, kick detection is performed through human sight and hands-on data interpretation, which is quite slow. But, due to the evolution of technology, monitoring systems, and algorithms, kick detection has streamlined quite significantly.

Automated kick detection systems now with the help of data from pressure, flow, and temperature sensors, and monitor the wellbore in real-time for the early signs of a kick. Immediate notifications of well control. Identifying the changes in the well conditions activates the control systems. Further, in detection systems, machine learning incorporated systems recognize patterns within the data to filter normal well conditions from a kick and well fluctuations.

- Wireless and Remote Well Control Operations

Another important specialized technology is the wireless control wells. Control technologies enable operators to reduce the number of people on the rig or well site, which is important for the safe and efficient management of people and equipment.Remote control systems allow the operation of blowout preventers and choke systems and the monitoring of pressure control from a control room. Deploying wireless downhole and surface sensors enables real-time access to data, allowing operators to make timely decisions while removing themselves from danger. This remote capability enhances safety by allowing operators to control the well from a distance while exposing them less to danger.

- 3D Wellbore Simulation Technologies

Incorporating 3D wellbore simulation technologies has become a key tool in well control, particularly for complex and/or deepwater wells. These technologies take advantage of real-time data, and, while using advanced technologies, create a dynamic, three-dimensional simulation of the with the wellbore and enclosing formation.

This chart illustrates the range of 3Dsimulation techniques are used to ensure well control during workover and well intervention, highlighting their role in improving safety, reducing risks and optimizing the effectiveness of interventions.

| Simulation Application | Description | Benefits |

| Well Control Simulation | Simulations model the wellbore and formation pressures, fluid dynamics, and the impact of kicks or influxes. | Allows for predictive analysis of well control issues, helps in planning safe interventions and operations. |

| Kick Detection Simulation | Simulates various kick scenarios to test response times and effectiveness of control equipment (e.g., BOPs). | Improves kick detection strategies and enhances the preparedness for real-world kick events. |

| Blowout Preventer (BOP) Simulation | Virtual testing of BOP functionality, including pressure testing, sealing, and activation. | Assesses BOP performance under different well conditions and ensures reliability in case of a blowout. |

| Mud Flow and Pressure Simulation | Models mud circulation rates, pressure profiles, and fluid dynamics to optimize well control during operations. | Ensures correct mud weights and flow rates are used, reducing risks associated with pressure imbalances. |

| Real-time Well Control Simulation | Simulates the real-time well environment, using live data inputs (pressure, flow rate, etc.) to predict future events. | Enables better decision-making by allowing operators to anticipate pressure changes and well behavior. |

| Wellbore Stability Analysis | Simulates wellbore conditions to assess stability during workover or intervention, including formation damage risks. | Helps identify potential wellbore integrity issues before they occur, reducing the risk of well failure. |

| Emergency Response Simulation | Simulates emergency scenarios, including blowout or kick events, to evaluate emergency response protocols. | Improves safety preparedness by allowing teams to practice and refine response strategies in simulated environments. |

| Integrated Drilling and Intervention Simulation | Combines drilling simulation and well intervention simulation in virtual environments to optimize operations of drilling and well control. | Enhances efficiency by simulating combined drilling and intervention operations for optimized performance. |

- Hybrid Drilling and Intervention Systems

Another area of innovation is the development of hybrid drilling and intervention systems. These systems integrate both drilling and intervention functions in a single operation, allowing for more efficient well intervention procedures such as sidetracking or wellbore cleanout, while maintaining complete control of the wellbore.

Hybrid systems use automatic drilling rigs paired with real-time systems that monitor and manage well pressures, allowing for the performance of advanced drilling interventions. These systems streamline the well control operations, decrease the time spent on the well and improve safety from workflow overhaul between drilling and interventions control.

Summary

Well control during workover and well interventions is an essential part of the oil and gas industry and entails significant attention to detail, the right equipment, and trained personnel. If all well control steps are correctly executed, it can decrease the risk, improve safety and maintain well integrity. These continued iterations, paired with advanced technologies and best practices from the industry, will provide the operators with safer well operations.