Casing and Cementing in Drilling for Ensuring Well Integrity

During the drilling of oil and gas wells, casing and cementing are two vital operations that maintain the integrity and safety of the well throughout its productive life. The two processes work together to mitigate the risks of fluid migration, wellbore collapse, and groundwater contamination. The article analyzes the importance, techniques, challenges and technical innovations associated with casing and cementing in drilling.

What is Casing in Drilling

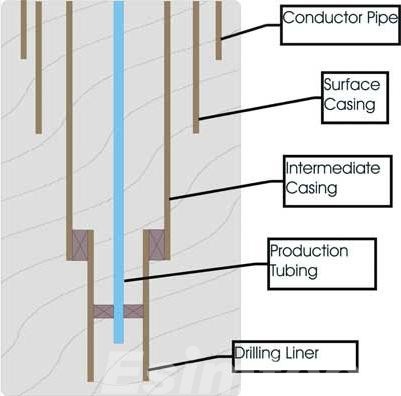

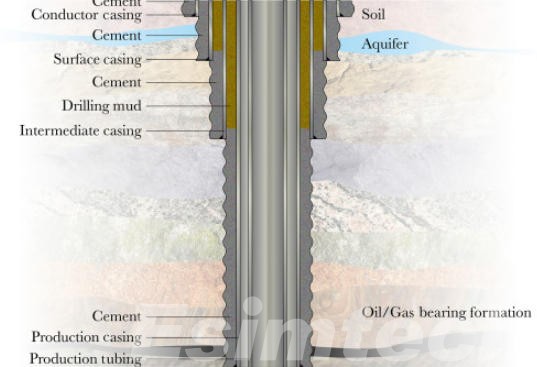

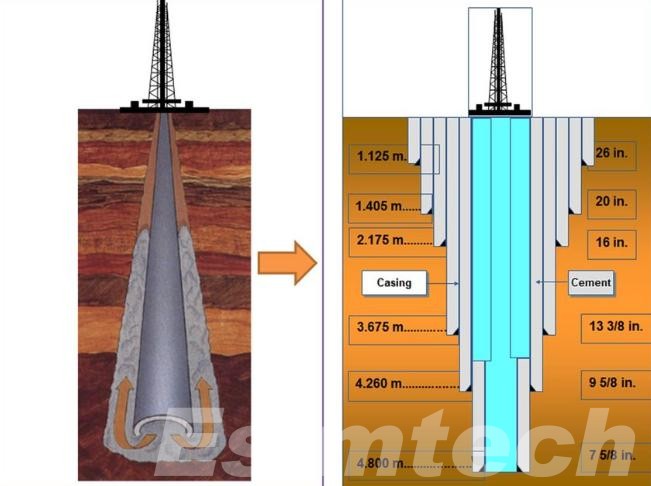

In drilling, casing refers to the installation of a sequence of steel pipes, known as casing strings, to the drilled wellbore. The primary purpose of the installation of the casing is to provide necessary structural support to the wellbore and prevent collapse of the wellbore during the drilling operation, while also segregating and stabilizing the sections of the rock to control unwanted fluid migration.

In addition, casing prevents well contamination by sealing water zones, hydrocarbons, and gas pockets, thereby protecting groundwater. Casing installation involves multiple stages, and a string of casing will be used for the deeper parts of the well.

This chart outlines the common casing strings and their purpose at each stage, providing an overview of how the well is structured to ensure stability and isolation throughout the drilling process.

| Casing String | Purpose | Depth Range | Installed After |

| Surface Casing | Protects shallow formations, prevents contamination of groundwater, and supports the wellhead. | Shallow depth, usually the first 300-500 meters | First casing string after initial drilling |

| Intermediate Casing | Isolates deeper formations and provides additional wellbore stability. Protects against pressure from deeper formations. | Deeper sections of the well, often several thousand meters | Installed after surface casing is set |

| Production Casing | Isolates the production zone from surrounding formations, allowing hydrocarbons to flow from the reservoir to the surface. | Final depth before reaching the target production zone | Installed after drilling the intermediate section |

| Liner Casing (if applicable) | Used to line a specific section of the well to isolate problematic zones or to increase wellbore stability. | Typically placed in deeper, lower sections of the well | Can be installed in place of or in addition to production casing |

What is Cementing in Drilling

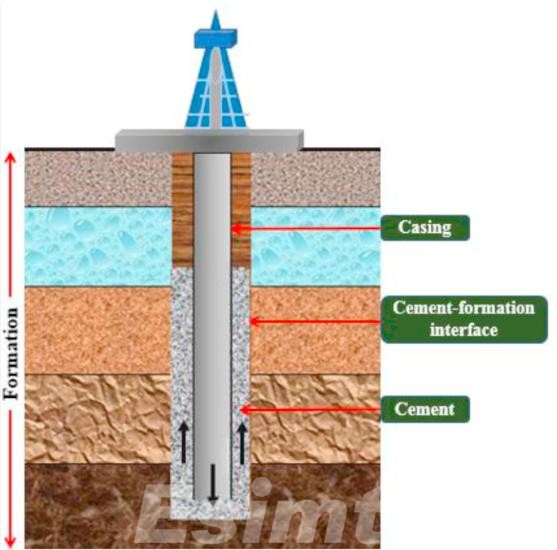

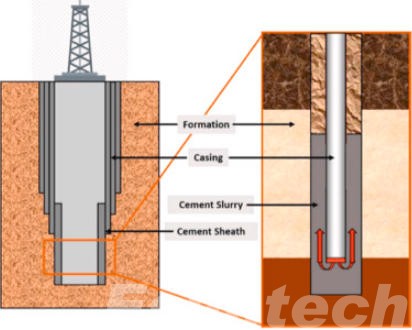

Cementing is the process of pumping cement slurry into the annular space between the casing and the wellbore. The primary purpose of cementing is to provide hydraulic isolation between the wellbore and the surrounding geological formations. Cement bonds the casing to the formation, preventing fluid migration and maintaining wellbore integrity.

Cementing also acts as a barrier against the escape of gas or water into the wellbore, allowing fluids to flow only from the targeted production zones. Properly executed cementing guarantees a protective seal and saves the operator from expensive complications that include blowouts and the contamination of water-bearing formations.

The Process of Casing and Cementing in Drilling Operations

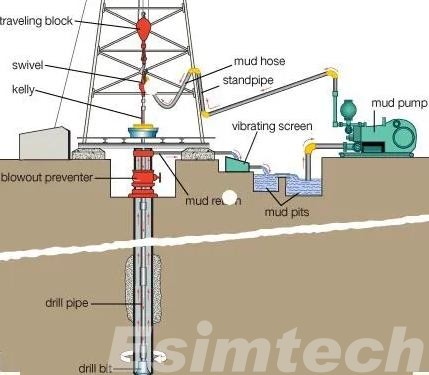

1. Drilling the Wellbore

The sequence of activities in an operation commences with the drilling of the wellbore using a rotating drill bit that slices through the sub-surface rock formations. Drilling fluids or muds serve multiple purposes: they cool the drill bit, transport the rock cuttings to the surface, and assist in pressure control within the wellbore. The drilling phase is concluded once the wellbore has reached the anticipated depth for the installation of casing.

2. Preparing and Running the Casing

Once the desired depth for the drilling of the wellbore has been achieved, the next stage is the preparation for the installation of the casing string. The casing, which is usually made of steel, is designed and fabricated in sections for ease of installation, which are then linked together as they are lowered into the wellbore. The number of casing strings depends on the well depth and the characteristics of the rock formations that surround it.

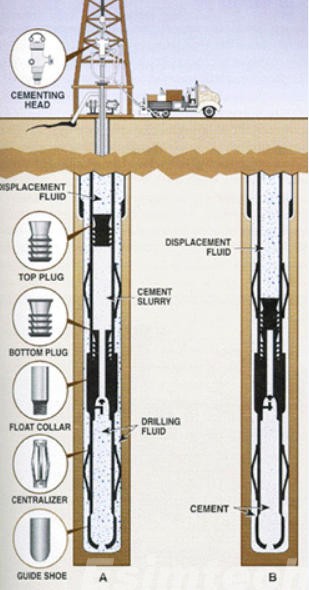

Lowering a casing string down a wellbore is performed usually with a drilling rig. The casing is equipped with centralizers, which will keep the casing centered in the wellbore and maintain an even spacing of the cement. The casing string is now ready to be cemented.

3. Cementing the Casing

Cementing is performed after the casing has been placed within the wellbore and is in the desired position. A cementing slurry with appropriate design characteristics is prepared, and sometimes includes other materials to adjust setting time, set strength, or gas flow mitigation. The slurry will be pumped down the casing and into the annular space between the casing and the wellbore.

While the cementing slurry is filling the annular space, it will displace the drilling mud and other wellbore fluids. This will allow the cement to solidify and form a barrier. After the cement has reached the surface of the wellbore, the cement will set and form a rigid bond to the wellbore.

4. Allowing the Cement to Set

Once the cement has been pumped in place, the cement will essentially be allowed to set and cure. As for how long the cement takes to harden, this depends on the depth of the well and specific cement mix, and can be anywhere from hours to days. During this period, the cement becomes bonded to the casing and the surrounding rock formations, which will achieve hydraulic isolation, and support wellbore.

5. Pressure Testing the Well

As the last step in the pressure testing sequence, once the cement has set, the well is subjected to high-pressure conditions to ensure the seal is intact. If the pressure test is successful, the casing is deemed securely cemented and the well can be drilled or produced.

6. Further Cementing if Necessary

When gas migration or poor cement bonding is detected, or the well is put into production, pressure testing and remedial cementing operations may be required. This may involve re-cementing sections of the well to ensure the wellbore is sealed and that the formation zones are isolated in the proper sequence.

Challenges in Casing and Cementing Operations

This chart provides the common challenges faced in casing and cementing, emphasizing the potential consequences of each issue and their impact on the overall integrity and success of drilling operations.

| Challenge | Description | Impact |

| Lost Circulation | Cement slurry is lost to porous formations during placement, preventing proper cement coverage. | Reduces the effectiveness of the cement seal, leading to potential fluid migration and wellbore instability. |

| Wellbore Deviations | Irregularities in wellbore geometry make it difficult to center the casing and ensure uniform cement placement. | Can cause uneven cement distribution, leading to incomplete sealing and poor zonal isolation. |

| High Pressure and Temperature | Extreme pressure and temperature conditions affect the cement's ability to set and bond effectively. | May lead to poor bonding between the casing and formation, increasing the risk of gas migration or well failure. |

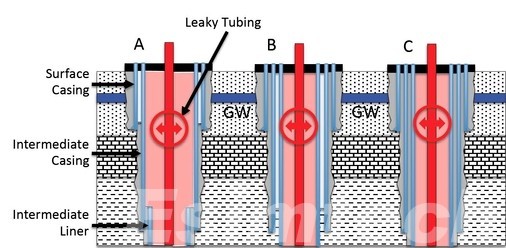

| Gas Migration | Gas may migrate through the cement before it fully sets, causing channels and reducing the integrity of the seal. | Results in incomplete isolation of formation zones, potentially causing well control issues like blowouts. |

| Cement Bonding Issues | In some cases, the cement fails to bond properly to the casing or formation due to issues with the cement slurry or curing. | Leads to poor well integrity, potential fluid leaks, and reduced wellbore stability. |

| Inadequate Mud Removal | Failure to properly displace drilling mud from the wellbore before cementing can affect the cement's ability to bond. | Reduces the bond quality between the casing and formation, leading to potential migration of fluids and instability. |

| Formation Damage | Certain formations may be reactive to cement slurry, causing physical or chemical damage. | Can compromise the integrity of the well and create additional challenges in achieving a secure seal. |

Technological Advancements in Casing and Cementing Practices in Drilling

Over the years, advancements in technology have vastly improved the effectiveness of casing and cementing practices to a point where wellbore stability, zonal isolation, and overall integrity of the well are something to be confidently relied upon.

1. Advanced Cementing Materials

One of the most important advancements in casing and cementing technology is the use of advanced cementing materials. Although traditional cement mixtures work under normal situations, they are inadequate in the extreme conditions of depth or high pressure in wells. Consequently, a variety of specialty cement materials has emerged to cater to the advanced needs of modern drilling.

This chart summarizes the various types of advanced cementing materials that enhance the performance, stability, and longevity of cement jobs in oil and gas drilling operations. Each material is tailored to meet specific well conditions, ensuring wellbore integrity and efficient cement placement.

| Advanced Cementing Material | Purpose | Key Features | Applications |

| High-Temperature Cement | To withstand extreme temperatures found in deep or geothermal wells. | Can endure temperatures up to 500°F (260°C) or higher, ensuring long-term well integrity. | Used in ultra-deep wells, geothermal reservoirs, and high-temperature environments. |

| Gas-Blocking Cement | Prevents gas migration through the cement during the setting process. | Contains additives that block gas channels, ensuring a solid bond between casing and formation. | Applied in wells with gas zones or when gas migration is a concern. |

| Lightweight Cement | To reduce the weight of the cement slurry while maintaining adequate strength. | Reduces the overall weight of the cement, minimizing risks to weak formations and lowering lost circulation risks. | Used in deep wells or those with weak or porous formations. |

| Polymer-Enhanced Cement | To improve the bonding strength and flexibility of the cement. | Contains polymers that enhance strength, prevent cracking, and provide better sealing. | Used in challenging environments where cement needs additional durability. |

| Micro-Enhanced Cement | For better flow and placement in narrow annular spaces. | Contains fine particles that improve the cement’s ability to flow into tight spaces and provide better zonal isolation. | Applied in horizontal wells or narrow annular spaces. |

| Resin-Modified Cement | To increase the resistance of cement to chemical attack and cracking. | Provides enhanced durability in aggressive formations with high levels of H2S or CO2. | Used in corrosive environments or where higher chemical resistance is needed. |

| Self-Healing Cement | Allows the cement to repair itself if cracks develop. | Contains microcapsules that release a healing agent to fill any cracks or voids in the cement. | Used in wells that require long-term performance and additional protection against wellbore integrity issues. |

| Delayed-Set Cement | To extend the time before the cement sets, allowing for better placement. | Provides flexibility in wellbore operations and ensures more time for accurate cement placement. | Applied in deepwater drilling or complex wells where additional time is needed for cement placement. |

| Expanded Cement | To increase the volume of the cement slurry for better isolation. | Expands after setting, filling gaps and providing a more uniform bond. | Used in high-pressure formations where better zonal isolation is required. |

2. Casing Centralizers

Casing centralizers are more recent technological innovations. Their contribution to the quality of the casing and cementing operation has been invaluable. These attach to the casing and ensure that the casing is properly centered in the wellbore. This is important because proper casing centralization allows for even cement coverage of the casing which is necessary for zonal isolation and the integrity of the well.

Initially, centralizers consisted of purely mechanical components, employing spring-loaded arms or bow springs to exert pressure on the casing, forcing it to the bore of the well. Though these traditional centralizers were functional, they encountered challenges on highly deviated irregular wellbores. Therefore, the complications created the need for advanced hydraulic centralizers, employing hydraulic pressure to centralize the casing to the bore of the well. Compared to traditional mechanically powered centralizers, hydraulic centralizers allowed for more effective manipulation of casing placement where even inconsistent cementing is addressed, particularly for complex wellbores.

In the modern drilling, centralizers, whether mechanical or hydraulic, have become an inevitable addition, for they provide the ability to position the casing and cementing quality, which impacts well integrity and failure, positively.

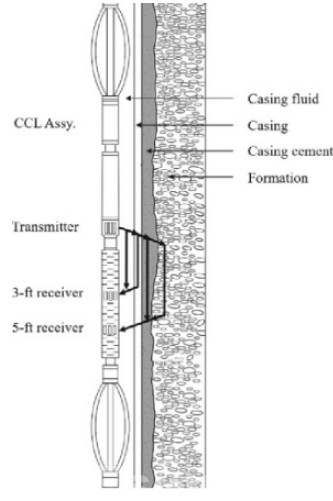

3. Cement Bond Logging (CBL)

With the growth of reliable and efficient cementing operations, the ability to assess the quality of a cement job improved due to the technology surrounding Cement Bond Logging. CBL is a diagnostic tool that positions and assesses the bond of cement with casing and the bond integrity along the wellbore utilizing ultrasonic waves.

Prior to the deployment of CBL, the evaluation of the quality of the cement bonds was primarily attributed to visual appraisal or pressure tests, which, in most instances, provided insufficient insight on the performance of the cement. By employing Cement Bond Logging, operators are able to pinpoint weak spots, gaps, or poorly bonded areas of cement that may go undetected by other means. This technology can diagnose gas migration, channeling, and poorly sealed cement, which enables operators to carry out remedial cementing activities before problems escalate into hazardous fluid loss or blowouts.

Cement bond logging provides the most value in complicated wells, particularly those with lengthy horizontal segments, multiple casing strings, or those being drilled through difficult formations. CBL augments the decision-making process for remedial cementing, which enhances the overall safety and reliability of the well, by continuously providing information on the quality of the cement job performed.

4. Advanced Cementing Equipment

Optimizing casing and cementing operations relies on advances in not only materials and diagnostic technology but also cementing equipment. With the introduction of automated cementing units, control over all phases of the cementing operation has become more streamlined and the procedure more cementing process within defined and monitored parameters. These systems oversee the crucial phases of cement mixing and pumping, and cement delivery, all in real-time, while monitoring the pressure closely to ensure it matches the required specification.

The introduction of automation has improved operational efficiency through the real-time control of automated systems, which are designed to monitor well conditions, such as pressure and temperature, in order to make adjustments to the cement slurry. Cementing, bonding, and setting conditions are optimally configured with the precise control of automated systems. New generation cementing units display a growing concern for the environment through energy efficiency, in an era of diminishing environmental resources.

5. Real-Time Monitoring and Data Analytics

The use of real-time monitoring and data analytics in casing and cementing operations is transforming the industry. With the use of advanced sensors and data collection systems, operators can actively track variables such as cementing pressure, temperature, and flow rates. Data is analyzed to optimize the cementing procedure, anticipate concerns, and enhance the efficacy of decisions.

The ability to monitor data in real-time is useful when operators need to troubleshoot problems during the cementing stage. For example, unexpected fluctuations in pressure may signal lost circulation or gas migration. This real-time analysis allows operators to take prompt corrective actions, minimizes complications, and increases the operational success rates.

6. Simulation Technologies

This chart outlines how oil and gas simulation technologies help optimize casing and cementing operations by modeling various processes, predicting potential issues, and improving decision-making.

| Simulation Technology | Purpose | Benefits | Applications |

| Cementing Simulation Software | Models the cement slurry behavior, placement, and setting process. | Optimizes cement slurry design, predicts flow behavior, and ensures uniform placement. | Used for simulating cementing operations in deep, high-pressure wells. |

| Wellbore Simulation | Simulates wellbore stability, casing placement, and cement bonding. | Predicts wellbore issues like lost circulation, gas migration, and poor cement bonding. | Used in planning casing and cementing operations for complex wells. |

| Hydraulic Simulation | Models the pressure and flow of cement slurry during placement. | Ensures optimal cement slurry displacement and helps avoid issues like overpressure or improper cement distribution. | Applied in optimizing pumping rates and pressure control during cementing. |

| Gas Migration Simulation | Simulates gas behavior in the wellbore during cement setting. | Helps prevent gas migration during cementing and ensures solid bonding. | Used in wells with known gas pockets or shallow zones prone to gas migration. |

| Cement Bonding Models | Simulates the cement bond formation between casing and formation. | Assesses the quality of the cement job and predicts long-term wellbore integrity. | Used to evaluate cement bond quality and identify potential weak spots. |

| Temperature and Pressure Modeling | Simulates the effects of temperature and pressure on cement properties. | Optimizes cement formulations for high-pressure, high-temperature environments. | Essential for deep wells and geothermal projects where extreme conditions exist. |

| Remedial Cementing Simulation | Models remedial cementing operations when initial cementing fails. | Predicts the effectiveness of remedial cementing and helps refine the process. | Used when gas migration or poor cement bonding is detected after initial cementing. |

| Well Integrity Modeling | Simulates the long-term performance of the casing and cement under different operational conditions. | Enhances wellbore stability and reduces the risk of future failures due to casing or cement issues. | Applied throughout the lifecycle of the well, from drilling to production. |

Wrap Up

The cementing and casing processes are critical for ensuring safety, reliability and operational efficiency of oil and gas wells. Each operation, when performed properly, serves to prevent contamination, stabilize the wellbore and isolate reservoir fluids to enhance production. Though challenges do occur, the oil and gas industry is increasingly relying on improvements in cementing and casing to reduce operational costs.