Common Reasons for Performing Workover Operations

Workover operations sit at the heart of every oil and gas well’s life. They give crews a chance to fix trouble spots and keep output flowing. Tubing swaps, cleanouts, gear upgrades- you name it, fast follow-up on these tasks stretches a well’s career and guards people on location.

Basics of Workover Operations?

Workover operations are the suite of interventions carried out on a producing oil or gas well to restore, upkeep, or lift output. Whereas the first drilling program opens the wellbore, a workover targets a completed well that has already yielded hydrocarbons. Such work may involve straightforward chores-e.g., swapping out damaged tubing or more elaborate tasks like acidizing the reservoir or upgrading surface gear.

Field crews mobilize a compact, self-contained rig far smaller than a drilling platform; it is outfitted to hoist, latch, and run tools safely into the hole. The aim is to remedy the problem without the delay or expense of spudding an entirely new well. By carrying out regular workovers, operators keep the well productive, mitigate safety hazards, and meet environmental rules. Over the long haul, these visits prolong reservoir output and protect the money invested in drilling and infrastructure.

Common Reasons for Performing Workover Operations

Workover operations are vital maintenance trips mounted on oil and gas wells after initial drilling and completion, aimed at restoring or boosting output. During the time a well is in service, a variety of mechanical or chemical problems can arise that curtail production. The reasons set out below capture a few of the more frequent triggers that prompt a workover crew to mobilize.

Tubing Failures and Replacements

Production tubing acts as the main pipeline carrying reservoir fluids up to surface facilities. With months or years of exposure to corrosive gas, abrasive sand, scaling, and pressure cycling, the pipe ultimately fatigues or holes. If uncorrected, those weak spots cause leaks, drop wellhead pressure, or entirely cut off flow. A workover permits the crew to fish out the damaged lengths and slide in fresh tubing, thus sealing the well and restoring normal rates.

Wellbore Cleaning and Sand Removal

Many soft formations yield significant quantities of loose sand, scale, or wax that pack inside the hole and block flow. The resulting plugs rob production, wreck pumps, grind valves, and push the entire system toward unplanned shutdowns. During a workover, operators run bailers, jetting gadgets, or coiled-tubing sweeps to scrub the bore and float the grit to surface. Clearing those impediments revives smoother delivery and spares the operator from expensive rig stand-bys.

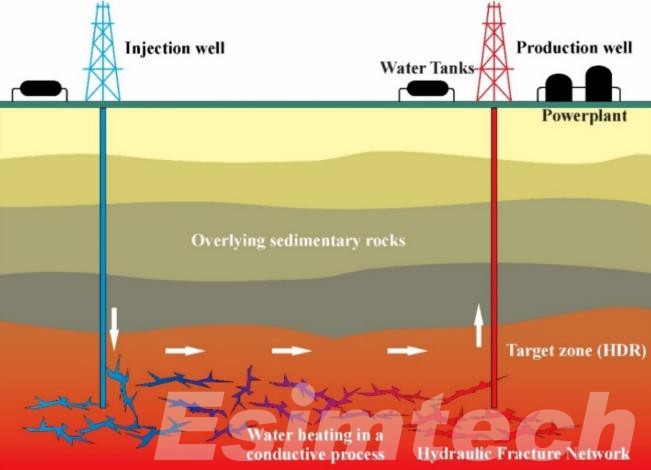

Reservoir Management and Stimulation

Over time the pressure inside a mature reservoir drops, and production naturally slows. Brief workover trips let crews revive output by treating the reservoir. Acid washes, hydraulic fractures, and targeted water-shutdown jobs reopen pathways between the wellbore and formation. These repairs are crucial for lifting total recovery and pushing the wells profitable lifespan.

Equipment Upgrades or Repairs

Every well carries downhole gear and surface devices-pumps, packers, safety valves, and more. Wear and tear, corrosion, or simply newer designs soon make many parts obsolete. Routine workovers thus provide a chance to inspect, fix, or swap them out. Sometimes operators seize that window to install smart controls or other upgrades that match shifting production goals. Keeping hardware modern through planned workovers safeguards safety, output, and compliance with regulators.

By treating these challenges promptly, producers protect rates, dodge expensive failures, and secure the long-term health of their wells.

Benefits of Timely Workover Operations

Scheduling workover jobs at the earliest prudent moment boosts the output, safety, and cost-effectiveness of oil and gas wells. When operators put off these needed visits, production can plunge, machines can break, and the well itself can turn dangerous. The major gains that come with acting on time include:

- Enhanced Production Rates: As months pass, sand, scale, or lower reservoir pressure steadily choke a wells flow. A quick workover clears the bore, mends the tubing, or re-energizes the rock so output returns to peak levels. Taking this step early curbs long shutdowns and captures more hydrocarbons over the life of the well.

- Extended Well Life: Routine workovers also protect the wells structure from corrosion, wear, and damage. Fixing problems before they worsen delays the day of expensive abandonment and stretches the assets usefulness for years.

- Improved Safety & Reduced Risks: Neglecting timely repairs can lead to serious incidents, including leaks or blowouts. Regular checks and swift fixes keep casings sound, limit environmental threats, and safeguard crews on location.

- Cost Savings in the Long Run: Though each workover demands cash upfront, that spend is tiny next to the tab for a sudden blowout or a dead well. Early fixes trim outages, preserve production income, and in the end hand operators a far better return.

When operators place a premium on prompt workover jobs, they boost efficiency, improve safety, and secure higher profits from each well.

How Can Workers Practice Workover Operations?

Practicing workover operations safely and effectively requires a combination of theoretical knowledge, hands-on training, and the use of advanced simulation technologies. Because workover tasks often involve high-pressure equipment and complex well conditions, workers must be well-prepared before stepping onto the rig.

Hands-On Training and Field Experience

One of the most effective ways to train workers is through direct field experience under the supervision of seasoned professionals. Trainees learn how to:

Run work-over rigs and their supporting gear Maneuver tubing, packers, and well-control hardware Execute routine jobs such as pulling and running tubing, fishing, and zonal isolation Observe safety rules and practice emergency steps

Such firsthand exposure deepens confidence and sharpens the quick judgment needed on the rig. Still, in unusual or high-hazard circumstances, practical field training should be supplemented by controlled simulations or classroom drills to ensure readiness without undue risk.

Workover Simulators: Safe, Realistic Training

To complement hands-on learning, many training programs now incorporate Workover simulators—advanced digital platforms that replicate real-life well conditions in a controlled environment. These simulators allow workers to practice key tasks such as:

Well control during unexpected pressure events

Equipment troubleshooting and diagnostics

Procedural drills like tripping in and out of the hole or conducting stimulation operations

Using real-time data, 3D visuals, and interactive controls, workover simulators can replicate both routine operations and complex emergency scenarios. This helps trainees build critical thinking and problem-solving skills without the risks associated with live operations.

Classroom and Online Learning

A solid grasp of theory still matters as much as hands-on practice. Workers can either sit in a classroom or log in from anywhere to cover: the science behind workover jobs and how reservoirs react; specs for key tools plus upkeep calendars; and the safety and environmental rules every crew must follow.

That groundwork lets staff know not only the steps to take but also why each one protects wells and boosts production. When it pairs with on-site drills, simulator runs, and regular refreshers, the blend builds the skill needed to work safely, quickly, and with self-assurance. Upgrading people through modern tools-like workover rigs mounted on a trainer-then pays off in smoother jobs and fewer expensive errors on the pad.

Grasping why operators routinely carry out workover jobs enables oil and gas firms to boost output, steward reservoirs more wisely, and trim future expenses. Whether the task involves changing tubing, sweeping the wellbore, or installing new gear, every intervention protects a well’s longevity and efficiency. When companies commit qualified crews and act without delay, they keep their assets productive and secure for many years.