Effective Methods for Well Intervention in the Deepwater Environments

In the deepwater environments, well intervention is important for sustaining the production and the performance of offshore oil and gas wells. Operators deal with perplexing well integrity challenges as exploration moves into deep waters over 1500 meters. Maintaining production and managing mature fields is also an important component. Deepwater well intervention requires specialized tools, vessels, and operational plans to perform maintenance, repairs and diagnostic protocols under extreme subsea conditions.

Understanding Deepwater Well Intervention

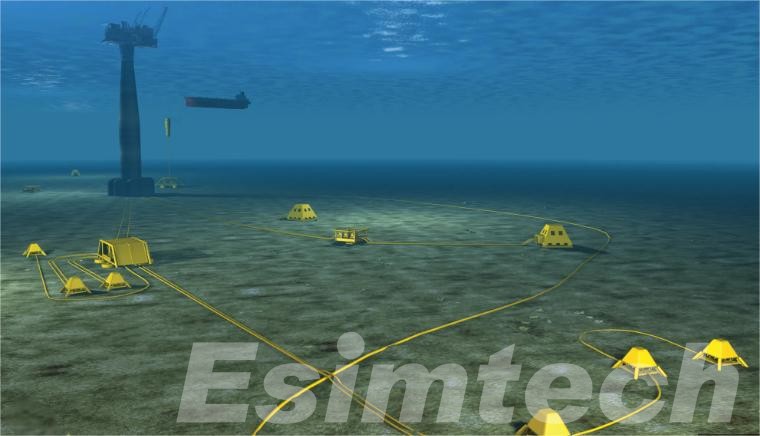

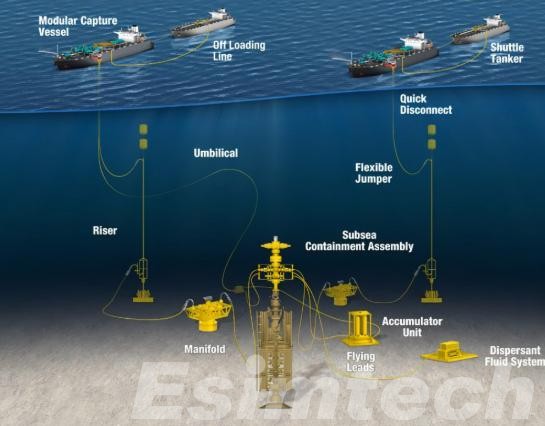

Deepwater well intervention focuses on the maintenance and performance improvement of subsea wells by using advanced technologies and special equipment to substitute for problematic full drilling operations. The interventions typically occur at depths greater than 1500 meters where subsea wellheads sit on the seabed and are linked to surface facilities via complex systems of risers, umbilicals, and control lines.

Deepwater well interventions aim to restore production and deal with problematic water or gas breakthroughs, remove blockages, repair incomplete equipment and conduct diagnostic tests.

Types of Deepwater Well Intervention

This chart outlines the major types of deepwater well intervention, along with their key operational methods, equipment, and applications.

| Type of Intervention | Description | Equipment Used | Typical Applications |

| Riserless Light Well Intervention (RLWI) | Conducted without a riser connection between the vessel and the subsea wellhead, using dynamically positioned vessels for light maintenance tasks. | Light intervention vessels, wireline or coiled tubing units, subsea lubricator systems, ROVs. | Scale removal, well logging, valve operation, chemical stimulation, and plug setting. |

| Riser-Based Intervention | Involves connecting a marine riser from the surface vessel to the subsea wellhead, enabling full wellbore access for complex operations. | Intervention riser systems (IRS), workover control systems, heavy intervention vessels, BOP stacks. | Tubing replacement, fishing operations, major mechanical repairs, and recompletion. |

| Coiled Tubing Intervention | Uses a continuous steel tubing string inserted into the well for pumping fluids or performing mechanical work. Suitable for both riser-based and riserless setups. | Coiled tubing reels, injectors, control heads, and subsea pressure control equipment. | Acidizing, scale removal, nitrogen lifting, debris cleanout, and perforation washing. |

| Wireline Intervention | Employs electric or slickline cables to deploy tools into the well for diagnostic or maintenance purposes. | Electric line or slickline winches, pressure control equipment, subsea lubricators. | Logging, plug setting or retrieval, valve actuation, and downhole data acquisition. |

Technical Challenges of Well Intervention in the Deepwater Environments

Conducting well interventions in deepwater environments presents unique challenges

- Extreme Pressure and Temperature Conditions

Working in deepwater environments, one of the primary technical challenges is the exposure to high pressure and also low temperature. At 1500 meters the pressure gets to over 10,000 psi and the temperature gets to near 0 degrees. These conditions impact the performance of the intervention gear, the hydraulics, and the electronics. All of the materials and instruments in use need to be over designed in strength, corrosion resistant, and able to compensate for losing pressure to be trusted.

- Limited Accessibility and Remote Operations

Deepwater wells pose unique challenges since they are on the seabed, and there is no human access to them. All of the advanced equipment, ROVs, and subsurface intervention systems must operate automated in an advanced manner of offshore oil and gas systems. The technology disconnect poses challenges for what should be standard practice, like opening valves and retrieving tools. The people to perform the task are there, but they must rely on telemetry and video systems, keeping everything tightly controlled and automated.

- Complex Well Architecture

Deepwater wells are equipped with complex completion systems which can have multiple production zones, intelligent well elements, and control lines. The advanced systems enable optimized production while presenting real challenges when it comes to intervention. The well’s internal systems are complex and therefore, require specialized tools and control that are high precision to avoid damage to the valves, sensors, packers, and other critical internal components critical to the well.

- Equipment Reliability and Durability

Deepwater intervention tools and other equipment are subjected to constant mechanical stress and corrosive elements. At these great depths, equipment failures can lead to high costs, dangerous situations, and production loses. Achieving reliability is accomplished by thorough pre-deployment testing, clever designs with built-in redundancy, and high-grade materials that can endure the brutal subsea environment for long usage periods.

- Real-Time Data and Communication Limitations

Well intervention requires real-time data for precise and accurate decision making. However, data sent from subsea tools to control units on the surface can have challenges due to bandwidth, time delays, and signal interferences. Inaccurate data communications impact monitoring and response times. Operational control can be greatly enhanced by pioneering telemetry systems along with subsea data processing.

- Vessel Stability and Weather Constraints

Deepwater interventions are conducted from dynamically positioned vessels. These vessels are required to maintain specific stability with respect to the wind, waves, and current, which is a challenge during interventions. These conditions also cause interruptions to the operation, and delays during the equipment deployment, or even cause equipment damage. Hence, predictive weather modelling, technology to compensate vessel movements, and the flexible scheduling are instrumental to ensure interventions are performed safely and without weather related

- Well Control and Safety Risks

Well control during deepwater operation is one of the most complicated and critical safety tasks. The high wellbore pressure combined with gas and fluid kicks makes subsea operations during deepwater interventions very difficult to control. Other than pressure and gas kicks, the most difficult to control situations are surges due to the remoteness of the operations. Multiple safety barriers, emergency disconnect systems, and blowout preventers (BOPs) are used to control these situations but reliability due to regular testing, monitoring, and systems integration is also a system safety component.

- Environmental Protection Requirements

Deepwater operations are performed in impactable areas of the global marine environment. Consequently, interventions, chemicals, and firefighting fluids are subject to even more scrutiny than the general discharge systems and associated environment standards. The complexities of deepwater containment and leak cleanup mandate even more comprehensive emergency response and environmental management systems to mitigate the probable extreme consequences.

Key Technologies Used in Deepwater Well Intervention

1. Remotely Operated Vehicles (ROVs)

Remotely Operated Vehicles (ROVs) play a vital role in deepwater well intervention. These unmanned, tethered robots are used for visual inspections, valve operations, and subsea equipment manipulations at depths where divers cannot go. ROVs are equipped with cameras and sensors, and perform precision tasks like wellhead inspections and real-time subsea monitoring. They are critical for mission safety and performance in deepwater situations, staying under high-pressure, low-visibility, and high risk-atmospheres.

2. Riserless Light Well Intervention (RLWI) Systems

Riserless Light Well Intervention (RLWI) systems are low-cost technologies that provide maintenance and diagnostic operations without a marine riser. Instead, it utilizes a subsea lubricator and control system that connects directly to the wellhead. This enables operators to perform wireline logging, scale removal, valve manipulation, and chemical injection operations from dynamically positioned vessels. Relatively, RLWI works in deep seawater while operational flexibility is preserved and the costs, setup time, and impacts to the environment are minimized.

3. Intervention Riser Systems

Intervention riser systems are needed for more complicated or heavy-duty interventions. This system creates a direct link between the surface vessel and the subsea wellhead, providing fully unrestricted access to the well. The riser captures and transports the fluids and mechanical tools needed for tubing replacements, fishing, and recompletions. The IRS also comes with safety equipment like blowout preventers (BOPs) and emergency disconnect systems, which protect well control and safeguard people and gear during sudden unforeseen circumstances.

4. Coiled Tubing and Wireline Tools

Deepwater interventions require technologies like coiled tubing and wireline tools for downhole operations. A coiled tubing system comes with a uniform steel tube that can be fed into the well to provide a fluid stream, remove obstruction, or perform mechanical tasks including milling and cleanouts. Wireline tools have a cable, either electrical or slickline, to transport tools for taking measurements, setting plugs, or controlling valves. These tools and systems enable the performance of many kinds of work and diagnoses without the need for a full well workover.

5. Subsea Control and Lubricator Systems

Subsea control systems and lubricators interface intervention tools with the subsea wellhead. They also allow the safe insertion and retrieval of tools in and out of the well under high pressure. In addition, they control the hydraulic functions, regulate the tools, and monitor pressure for safe and efficient operation. More advanced control systems offer real-time feedback and have redundancy, which makes the subsea tools safe and reliable under difficult deepwater conditions.

6. Real-Time Data Monitoring and Telemetry Systems

During deepwater well interventions, the absence of accurate real-time data can lead to grave consequences. Modern telemetry and remote monitoring systems stream data collected from downhole tools to surface operators in real-time, including pressure and temperature stamps, flow rates, and tool positioning, which is vital for effective communication with operators. Acoustic telemetry systems utilize fiber-optic cables to enable rapid communication over long subsea distances. Real-time data systems offer better control and enable the early detection of anomalies which can be vital in optimizing intervention procedures.

7. Dynamic Positioning (DP) Systems

Dynamic Positioning (DP) systems help deepwater intervention vessels keep the right amount of stability and position over the subsea wellhead. They utilize thrusters, sensors, and satellite navigation systems to maintain position and help overcome ocean currents, winds, and waves. This requires precision to keep the riser or cable from straining, and, most importantly, to protect the people and equipment nearby. Dew and DP systems permit more extensive and deeper water operations without the need to drop anchor.

8. Advanced Safety and Well Control Technologies

Deepwater intervention comes with enormous safety challenges. Subsea blowout preventers , Emergency Disconnect Packages (EDPs), and Shear-Seal Valves are just a few of the advanced well control systems that keep deepwater interventions safe. These systems can function independently or respond to remote-control signals to execute potentially dangerous pressure, flow, and emergency conditions. Well pressure and flow control systems grant automated response and rapid containment to crisis scenarios.

9. Simulation and Digital Twin Technologies

This chart provides how oil and gas simulation technologies are deeply integrated into planning, training, and execution phases of deepwater well intervention, enhancing both safety and operational performance.

| Aspect | Description | Benefits |

| 1. Operational Planning Simulation | Simulates various well intervention scenarios under deepwater conditions (pressure, temperature, currents) before actual field operations. | Helps identify potential risks, optimize procedures, and reduce non-productive time (NPT). |

| 2. Equipment Performance Modeling | Uses digital twins for coiled tubing simulation and evaluates the behavior of subsea tools, riser systems, and intervention vessels under load and motion. | Ensures tool compatibility and reliability, preventing equipment failure during deployment. |

| 3. Well Control Simulation | Simulates blowout prevention, fluid dynamics, and pressure control in real-time training environments. | Enhances operator competence, ensures well integrity, and strengthens emergency preparedness. |

| 4. Subsea Environment Simulation | Models ocean currents, seabed topography, and thermal gradients to anticipate environmental effects on intervention systems. | Improves accuracy of intervention planning and tool placement in complex deepwater terrains. |

| 5. Dynamic Positioning and Vessel Motion Simulation | Predicts how intervention vessels will behave under varying sea conditions during operations. | Supports stable intervention, reduces downtime caused by vessel drift, and improves safety. |

| 6. Remote Operated Vehicle (ROV) Simulation | Provides virtual training and operational practice for ROV pilots in complex subsea operations. | Increases efficiency and accuracy of ROV maneuvers, minimizing risks to subsea assets. |

| 7. Real-Time Data Integration Simulation | Combines sensor data, digital twins, and predictive analytics for live well monitoring and decision support. | Enables proactive adjustments during interventions, enhancing efficiency and reducing operational risks. |

| 8. Post-Intervention Analysis Simulation | Recreates completed operations digitally to analyze performance, equipment wear, and procedural efficiency. | Facilitates continuous improvement and knowledge transfer for future deepwater projects. |

Advantages of Deepwater Well Intervention

| Aspect | Advantages |

| Production Optimization | Helps restore or enhance well productivity by cleaning, stimulating, or re-perforating the wellbore. |

| Extended Well Life | Allows operators to repair damaged components and maintain integrity, thereby prolonging the productive lifespan of deepwater wells. |

| Cost Efficiency | Reduces the need for full-scale workovers or new drilling, significantly lowering operational costs compared to drilling new wells. |

| Improved Reservoir Management | Enables continuous monitoring, logging, and evaluation of reservoir conditions to optimize recovery strategies. |

| Enhanced Safety and Control | Modern intervention technologies maintain high safety standards and well control even in challenging subsea conditions. |

| Reduced Downtime | Quick interventions minimize production interruptions, maintaining consistent output and operational continuity. |

| Environmental Benefits | Targeted interventions reduce the environmental footprint compared to drilling new wells or abandoning existing ones. |

| Access to Complex Wells | Advanced intervention systems enable maintenance and repair of wells located in ultra-deepwater and harsh environments. |

| Flexibility of Operations | Technologies such as Riserless Light Well Intervention (RLWI) allow various tasks to be performed without heavy rigs. |

| Data Acquisition and Diagnostics | Real-time data from intervention tools improve understanding of well conditions and guide informed decision-making. |

Future Trends and Innovations of Well Intervention in the Deepwater Environment

Future trends of well intervention in the deepwater environment focus more on digitalization,automation, and being more environmentally sustainable.

- Integration of Digitalization and Artificial Intelligence (AI)

The role of digital technology in AI and deepwater well intervention is unprecedented. Advanced predictive AI begins to identify potential problems such as equipment failure, wellbore instability, and fluid anomalies by studying real-time downhole and surface data. Engineers can operate with digital twins, virtual models of wells and intervention systems, to simulate interventions, reducing risks and improving planning precision. These technologies optimize complex campaigns by improving decision-making, minimizing non-productive time, and maximizing the effective distribution of resources.

- Autonomous and Semi-Autonomous Intervention Systems

Deepwater well intervention is twice as safe with self-operating underwater systems. New models of Remotely Operated Vehicles (ROVs) and Autonomous Underwater Vehicles (AUVs) continue to evolve and operate with little human oversight while performing tasks geared toward deepwater well intervention, such as inspections, repairs, and monitoring. Not only are the tasks executed without human support, but the systems also adjust to real-time changes in autonomous modes and eliminate the need for support surface vessels. Self-operating intervention systems enhance safety and operational productivity while decreasing costs.

- Advanced Riserless Light Well Intervention Techniques

As the industry continues to develop, riserless light well interventions are still one of the most flexible and cost-effective options for deepwater operations. Riserless light well interventions will most likely develop deeper and more versatile operations with new control systems, higher-pressure ranges, subsea interfaces, and adaptable depth offerings. The ability to use hybrid systems that blend coiled tubing or wireline tools with riserless light well intervention systems will enhance the complexity of patient interventions, eliminating the need for cumbersome riser heavy operations. This innovation cuts vessel time, which, in turn, offsets carbon emissions and supports environmental responsibility.

- Real-Time Monitoring and Predictive Maintenance

The positive, transformative change that deepwater well intervention systems experience with new tech developments continues to grow with the ability to collect and analyze data in real time. Advanced downhole sensors, expected to provide continuous feedback to operations on temperature, pressure, flow, and vibration, will refine predictive maintenance algorithms. These features will transform the approach predictive maintenance takes towards unrecoverable failures, allowing proactive interventions. Enhanced real-time monitoring will improve operational and environmental safety, and substantially cut equipment costs and downtimes.

- Use of Robotics and Remote Operation Centers

The use of robotics in deepwater well intervention operations is changing the management of these operations. Robotic manipulators and subsea drones are able to carry out extremely accurate and sophisticated tasks such as operating valves, connecting pipelines, and inspecting them. At the same time, remote operation centers on the ground enable specialists to monitor and command offshore intervention activities remotely while being thousands of kilometers away. This method minimizes the amount of manpower needed on the rig, improves safety and improves team coordination.

- Sustainable and Low-Carbon Intervention Practices

The pressures to environmentally sustain operation of the oil and gas industry, particularly in the area of deepwater well intervention, is undeniable. Innovative designs introducing hybrid or fully electric propulsion to the vessels for offshore operations has helped sustain emission in these operations. Emission of environmentally unfriendly fluids is also now coupled with improved waste management. Sustainable practice is now a global standard as the energy transition begins to accelerate. Future interventions will concentrate on and perform environmental stewardship.

Summary

Well interventions in the deepwater environment are among the most complex engineering challenges built on a blend of control systems and deep operational know-how. While the offshore reservoirs are aging and production challenges are steadily increasing, well interventions at an integrated level will continue to be a growing demand. In the overtime deepwater settings, the oil and gas sector will be able to fully capitalize on the production of energy from deepwater resources while managing environmental risks, executing technologically advanced and value-driven well interventions.