How does Casing While Drilling Work for Wellbore Construction

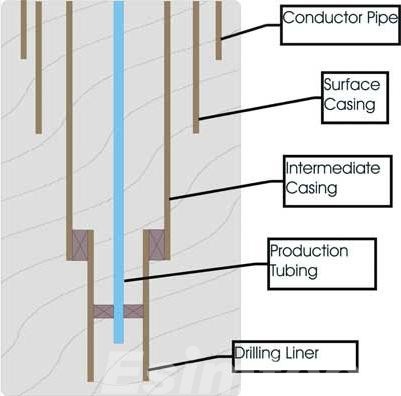

Casing while drilling (CWD) combines drilling and casing installation in one operation, drilling while simultaneously installing casing, a technique used in the oil and gas sector, and has a huge potential impact on wellbore construction, especially in difficult drilling and formation environments.

What is Casing While Drilling

Casing while drilling combines the operations of drilling and casing which traditionally involved an extra trip downhole and significantly lifted operational time and costs. Use of specialized equipment and techniques for casing while drilling provides enduring time and cost efficiencies on operational drilling as casing being attached to the well is integrated while the drill bit is engaged.

Key Components Involved in Casing While Drilling

This chart summarizes the key components and their roles in the Casing While Drilling process.

| Key Component | Description |

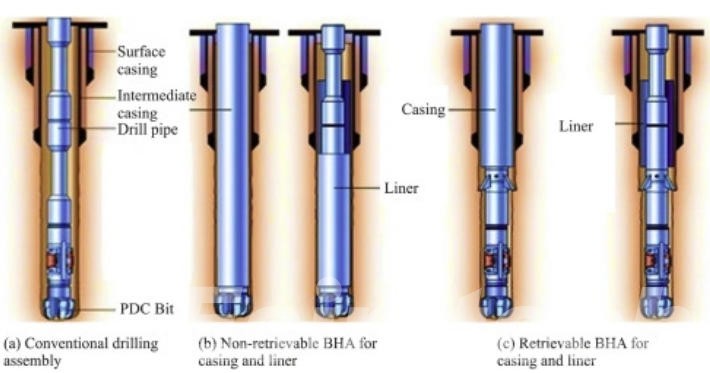

| Drill Bit and Drill String | The drill bit cuts through rock formations while the drill string is integrated with a casing running tool, allowing for the casing to be lowered simultaneously. |

| Casing Running Tool | A tool attached to the drill string that controls the insertion of casing into the wellbore as drilling progresses. Ensures accurate placement and smooth operation. |

| Casing String | Steel pipes inserted into the wellbore to stabilize the well. The casing is gradually run in as drilling continues, providing immediate wellbore support. |

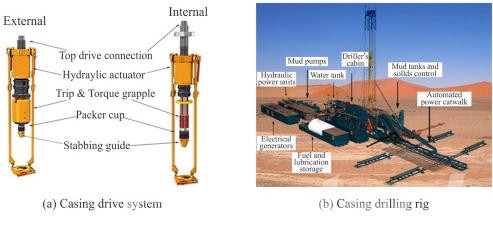

| Top Drive System | Rotates the drill string and provides torque for both drilling and casing running. It also ensures proper tension on the casing string for secure installation. |

The Step-by-Step Process of Casing While Drilling

Casing while drilling fundamentally merges two tasks that are usually performed in a sequential order: drilling and casing. In typical drilling practice, the entire drilling operation is carried out first, after which the casing is placed to secure the wellbore and sustain its integrity. Although these two operations are performed simultaneously while casing, the casing is still being run down the wellbore while drilling continues. For this to occur, specialized tools are required and teamwork of the drilling personnel and the casing running tool operator is needed.

Step 1. Initiation of Drilling

The entire process is initiated once the drilling rig is constructed, and operational activities are initiated in the wellbore. The drill bit is fitted to the drill string, and the operator begins the formation drilling process. The casing running tool is mounted on the drill string. This configuration makes it possible to run the casing into the wellbore while drilling is still in operation, further distinguishing casing while drilling from traditional drilling, as the casing is inserted after a section of drilling.

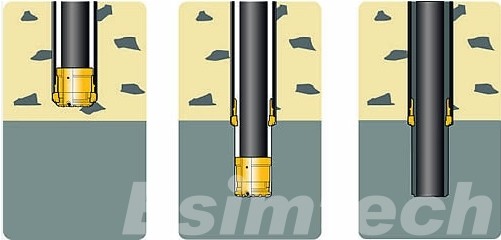

Step 2. Casing Insertion

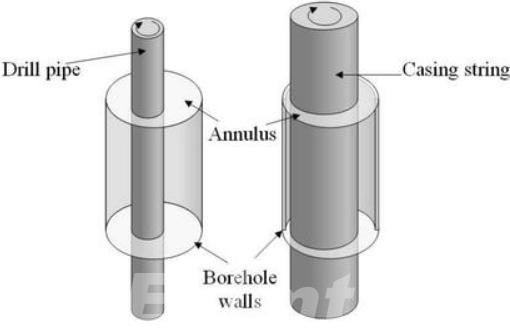

As the drilling operation progresses, the casing string, comprising multiple sections, is continuously lowered into the wellbore, coinciding with the depth attained by the drill bit. This technique of simultaneous drilling and running casing provides immediate wellbore stabilisation and integrity preservation, as it mitigates the risk of wellbore collapse. The casing running tools regulate the depth and casing position with precision to ascertain proper insertion.

Step 3. Continuous Drilling

While the casing insertion is underway, drilling activities persist. Here, the drill bit moves deeper into the designated rock formations while the casing is concurrently lowered. With the drill string and casing running tools integrated, one may achieve the desired outcome of drilling and casing in one continuous motion. In this way, the string of casing is advanced into the well, thus preventing wellbore collapse.

Step 4. Cementing the Casing

At this point, the casing reaches the specified depth, and the sequence for casing cementing begins. Cementing the casing is an essential step to make sure the casing is held in the wellbore securely and to permanently isolate the casing from fluids and pressures within the surrounding formation. This cementing procedure locks the casing in the cement sheath, providing well support, and also acts as a barrier to prevent leakage and fluid ingress from the surrounding formation. Once the casing is cemented, the wellbore also gets protection and is safe for the next phases of drilling, which facilitates safe drilling ahead.

Step 5. Continuous Casing for Deeper Sections

In these instances, there is a need to repeat the process of casing while drilling as the well is drilled. Along the line, for each wellbore section casing is added to maintain the structural integrity of the drilled section and to prevent formation collapse. This procedure can be performed sequentially with different casing sizes or classes, which vary according to the conditions of the formation and the well’s prescribed needs. Every time a new casing section is added, it is cemented to secure wellbore stability, safeguarding it in all depths.

Step 6. Drilling Continues with Stabilized Wellbore

In this phase of the operation, wellbore stability is maintained by the installed casing, and drilling continues until the cement setting process is concluded. This is possible because the wellbore stability is maintained by the casing and the risk of collapse is reduced. The quality of the wellbore is improved. This continuous operation of drilling and casing significantly streamlines the construction of the well, as multiple trips downhole to install casing are avoided, which minimizes downtime in the operation.

Key Advantages of Using Casing While Drilling

In challenging situations, particularly complex drilling environments, casing while drilling responds better than conventional drilling methods.

- Time and Cost Savings

The first category, which encompasses all lower operational costs, includes significantly reduced drilling time, which is a primary operational advantage Casing While Drilling offers. Cost savings are most pronounced in deep offshore environments and other high-risk, high-cost drilling settings; Casing While Drilling offers pronounced operational cost savings. In situations where the addition of casing would be operationally difficult, the time saving would be most pronounced in multiple casing scenarios. Casing While Drilling eliminates the need for additional trips downhole.

- Improved Wellbore Stability

In drilling operations, the risk of a wellbore collapsing or becoming damaged due to unsupported sections is a significant concern. While drilling, unstable formations, particularly shale, may cause a wellbore to remain unsupported, which may lead to collapse or damage. Casing while drilling mitigates these issues since casings are put in place as the well is being drilled. This allows the wellbore to receive support the entire time, which keeps the wellbore stable and prevents problems related to collapsing wellbores or stuck pipe. Issues are common in poorly consolidated formations and unstable conditions.

- Enhanced Safety

Safety is a primary concern in drilling operations, and Casing While Drilling (casing while drilling) directly addresses this concern by offering immediate wellbore protection. Well control is improved as casings are in place and can seal off formations, which prevents pressure and fluids from flowing into the wellbore. This reduces the risk of possible blowouts.

Also, casing while drilling reduces the number of downhole trips and the risk of related accidents. Real-time monitoring and automation in casing while drilling provide precise control in casing placement and reduce the possibility of error, which ultimately enhances safety.

- Reduced Rig Time and Equipment Wear

Because it eliminates extra casing runs, Casing While Drilling can shorten overall rig time. Multiple operations and equipment setups raise costs and increase wear and tear on drilling rigs and other equipment. Casing While Drilling streamlines the process, which reduces the time rigs are in use and the equipment changeovers needed. This reduces costs and increases equipment durability, lifespan, and efficacy.

- Flexibility in Challenging Drilling Environments

Casing While Drilling is highly beneficial in difficult drilling situations like deepwater drilling or drilling of High-Pressure High-Temperature (HPHT) wells, or in other forms of terrain that are metastable. Here, the need to case is immediate, and casing provides the support needed to overcome difficult-to-drill challenges. In these sinking wells, time is critically expensive, and casing While Drilling minimises both to position.

- Prevention of Formation Damage

When fluid ingress or pressure problems occur in the formation, damage to the wellbore and subsequent contamination issues can be avoided by casing While Drilling. Because casings are inserted during drilling, they provide an effective barrier between the well and the adjacent formations. This is important in high-pressure reservoirs where fluid influx occurs within the wellbore and can lead to instability, formation blowouts, and other dangerous situations. By casing While Drilling, protection of the wellbore is maintained so damage to the formation is minimised.

- Improved Drilling Efficiency

Having drilling and casing operations correlated leads to improved drilling efficiency in the construction of a well. Since casing While Drilling removes the need to perform a casing run, a significant amount of time and operational steps become streamlined. This increase in efficiency provides significant time savings in the drilling of a well. This time saving is important to operational efficiency in remote or offshore drilling locations where time on site is pivotal to cost savings.

- Better Reservoir Management

With casing while drilling, well integrity is maintained from the very beginning of the drilling process. This early casing installation helps minimise the risk of fluid migration, avoids the contamination of reservoir fluids, and helps control reservoir pressure, which is essential in optimising hydrocarbon extraction. Casing while drilling further stabilises the wellbore providing the opportunity for improved management of the reservoir, and thus, potentially, the overall production rates.

Applications of Casing While Drilling

This chart highlights how casing while drilling is applied in different drilling scenarios, optimizing efficiency and safety in each case.

| Application | Description |

| Deepwater and Offshore Drilling | casing while drilling is highly effective in offshore and deepwater drilling, where operational costs and time are critical. The process reduces downtime and the need for additional casing runs. |

| High-Pressure/High-Temperature (HPHT) Wells | In HPHT environments, casing while drilling ensures wellbore stability and protects against fluid influx, which is crucial for managing extreme pressure and temperature conditions. |

| Geothermal Drilling | casing while drilling is used in geothermal wells to manage high-temperature environments and ensure rapid construction with wellbore stability. |

| Shale and Unstable Formations | In shale and other unstable geological formations, casing while drilling prevents wellbore collapse by providing immediate casing support during drilling. |

| Offshore or Remote Locations | casing while drilling is particularly beneficial for remote or offshore drilling, where minimizing operational time and reducing logistical challenges are key. |

| Reservoir Protection | casing while drilling helps to prevent contamination of the reservoir by running casing immediately, ensuring better reservoir management and protection against fluid migration. |

Challenges and Considerations in Casing While Drilling

This chart highlights the primary challenges and factors to consider when implementing casing while drilling, emphasizing the importance of careful planning, equipment, and expertise.

| Challenge/Consideration | Description |

| Specialized Equipment Requirements | Casing While Drilling requires specialized tools like casing running tools, which may not be available on all rigs. The cost of this equipment can be high, and not all drilling operations are equipped for casing while drilling. |

| Complexity of Coordination | The coordination between drilling and casing operations is crucial. Both processes must be synchronized to ensure smooth casing installation, and any misalignment can cause problems like stuck casing or wellbore instability. |

| Torque and Drag Issues | Excessive torque and drag can occur when casing is inserted into the wellbore, especially in deep or deviated wells. Managing these forces requires careful control of drilling parameters and equipment. |

| Formation Compatibility | Some geological formations may be too unstable or challenging for casing while drilling. Soft or highly porous formations may collapse or damage the casing if not properly managed. |

| Wellbore Integrity and Pressure Management | Maintaining wellbore integrity is critical in casing while drilling operations. Pressure variations during drilling must be carefully controlled to prevent issues such as lost circulation or formation damage. |

| Cementing Challenges | Proper cementing of the casing is crucial. In casing while drilling, cementing must occur quickly after casing is installed, and any issues with cementing can lead to wellbore integrity problems. |

| Training and Expertise | casing while drilling requires skilled operators who are familiar with both drilling and casing operations. Lack of expertise can lead to operational mistakes and increased risk of failure. |

| Monitoring and Real-Time Adjustments | Real-time monitoring and adjustments are required to maintain optimal drilling conditions. Any deviations in casing installation or drilling performance must be addressed immediately to prevent complications. |

| High Initial Investment | The initial investment in casing while drilling technology and training can be substantial. This can be a barrier for some companies, especially if casing while drilling is not used frequently in their operations. |

Future Outlook of Casing While Drilling

The demand for greater efficiency, safety, and cost management in the oil and gas industry makes the future of casing while drilling very encouraging. Optimized drilling practices and the experience and technology advances make it likely that casing while drilling will become even more important to the future of drilling.

- Advancements in Automation and Digitalization

The integration of more automation and digital technology in casing while drilling is one of the more exciting trends in the industry. As automation technology improves, the casing while drilling process will benefit and be optimised by automation of real-time data collection and analysis. The combination of automated casing running tools and real-time monitoring systems will enable precise control of casing placement and significantly reduce the need for manual help, thereby limiting operational errors.

Moreover, more advanced AI and machine learning tools will be incorporated in the casing while drilling process to anticipate problems and make real-time suggestions. These tools will result in better operational efficiency, safety, and decision-making.

- Enhanced Wellbore Integrity with Smart Sensors

The future of casing while drilling will see the incorporation of more smart sensors embedded within the casing and drilling equipment. These sensors will provide continuous monitoring of pressure, temperature, and casing conditions in real time, enabling operators to adjust drilling parameters dynamically and address potential risks immediately.

With the growing importance of wellbore integrity, the integration of sensor-based feedback loops into casing while drilling operations will allow for more robust monitoring and optimization. This real-time feedback will further improve the prevention of issues like casing sticking, formation damage, and blowouts, enhancing both the safety and productivity of drilling operations.

- Integration with Other Advanced Drilling Technologies

The future of casing while drilling technology undoubtedly is the integration with Managed Pressure Drilling (MPD), Automated Drilling Systems and HTHP Drilling.

Casing while drilling coupled with MPD systems can control the pressure within the drilled column. This right control can help prevent formation pressure collapse and inflow control and collapsing drilled columns. Furthermore, automated drilling systems and casing systems can increase the operational efficiency of the drilled casing systems while decreasing the need for human control and manipulation. Systems can control the systems to a predetermined gyration and advanced manipulation for operational peak.

The combination of casing while drilling and other new technologies will likely decrease drilling time, improve wellbore stability and overall efficiency, thus making drilling activities quicker, safer, and more dependable.

- Broader Adoption in Challenging Environments

Due to the increasing demand for oil and gas, drilling activities are entering more complicated and difficult areas like deepwater, HPHT formations, and unconventional reservoirs such as shale plays. These areas need new and advanced methods, and casing while drilling is perfectly designed for such scenarios.

The coming years will see more developments in casing while drilling to help improve the features required to tackle tough formations. These formations will see improved wellbore stability, improved bottom hole pressure control, and faster drilling cycles. Most particularly, offshore and remote sites will see more benefits due to casing while drilling and its ability to improve operational efficiency, decrease the number of trips to run casing, and better well construction timing.

- Environmental Benefits and Sustainability

The adoption of casing while drilling innovations in the oil and gas industry is driven by an industry focus on decreasing environmental and sustainability impacts. casing while drilling reduces the number of trips the rig has to make downhole, resulting in a decrease in fuel consumed and a reduction in the emissions produced during drilling activities. With the reduction in the number of casing runs, the drilling operation also experiences a reduction in the waste generated during well construction.

Casing while drilling technologies will likely make use of low carbon energy adapted to the rigs, sustainable casing while drilling drilling fluids, and casing materials. These environmental casing while drilling innovations will enhance operational sustainability in oil and gas drilling in addition to having positive environmental impacts.

- Increased Focus on Data-Driven Decision Making

Digital transformation in the oil and gas sector focuses on casing technologies making use of AI and advanced analytics. Data generated from sensors, drilling devices, and numerous monitoring systems provide the basis to optimize workflows and streamline decision-making processes.

Advanced simulation technology has become an essential component of process optimization within casing while drilling. Simulations create virtual representations of drilling conditions that enable engineers to estimate performance, evaluate risks, and make adjustments to operational parameters, all prior to operational implementation in the field.

The different types of oil and gas simulations that improve the optimization process in casing while drilling, enhancing operational efficiency, safety, and the overall integrity of the wellbore, are represented in the following chart:

| Simulation Application | Description |

| Design Optimization | Simulations help optimize casing designs by modeling casing string behavior under various conditions (pressure, torque, and formation characteristics) to select the most suitable casing sizes and materials. |

| Wellbore Stability and Pressure Control | Simulations predict wellbore behavior under changing drilling conditions, ensuring wellbore stability and pressure management throughout the drilling and casing process. |

| Torque, Drag, and Friction Analysis | Simulations calculate torque and drag forces during casing installation, helping to minimize friction, optimize casing descent, and prevent stuck pipe incidents. |

| Operational Parameter Optimization | Advanced drilling simulators are used to determine the best drilling parameters (e.g., weight on bit, rotational speed, casing insertion rate) to enhance efficiency and reduce risks like formation damage or stuck casing. |

| Cementing Process Modeling | Virtual models simulate cementing operations to ensure proper casing cementing and bonding, predicting flow rates and pressure profiles to avoid issues like poor cement bonds or fluid migration. |

| Real-time Monitoring Integration | Simulations are integrated with real-time data, creating a digital twin of the operation, allowing for dynamic adjustments based on actual conditions and improving overall performance. |

| Risk Prediction and Mitigation | Simulations identify potential problems like casing deformation, lost circulation, or formation influx, enabling proactive solutions before actual drilling starts, reducing non-productive time. |

| Training and Scenario Analysis | Drilling training simulation systems are used to train drilling crews by replicating real-world drilling scenarios, allowing operators to practice responses to emergencies and unexpected situations in a virtual environment. |

- Cost Reductions and Economic Viability

Casing while drilling is likely to become less expensive as the required equipment becomes more readily available and affordable, particularly for deepwater offshore and unconventional drilling operations.

Over the next several years, more operators, even those in marginal fields or developing countries, are likely to gain access to more efficient automation technologies, leading to greater economies of scale with casing while drilling.

Final Thoughts

Casing while drilling employs advanced methods to merge drilling and casing operations, resulting in the construction of wellbores with unprecedented efficiency, safety, and cost advantages. The ability to minimize operational time, enhance the stability of the wellbore, and simplify overall processes makes casing while drilling an industry milestone. Although some implementation challenges still exist, many innovative drilling operations find it highly desirable considering its numerous advantages. The continuous advancement of technology indicates that casing while drilling will become more essential to the future oil and gas drilling operations.