How the Future New Techniques Revolutionize Oil Production

It is under increasing pressure to improve production efficiency and reduce environmental impacts in the oil and gas industry. To meet this challenge, the industry is adopting a new generation of recovery and extraction technologies that are expected to change the way oil is produced. The future new techniques for oil production are characterized by a blend of digital technology, eco-friendly sustainable processes, and greater exploration of reservoirs with complex structures.

Current Techniques Used for Oil Production

| Technique | Description | Common Applications | Limitations |

| Primary Recovery | Natural reservoir pressure is used to move oil towards the surface. | Early-stage oil fields | Only 5 to 15 percent of the original oil was in the first place |

| Secondary Recovery (Water Flooding) | Injects water to keep reservoir pressure and to displace oil. | Mature fields | Requires a water source, carries the risk of water leakage |

| Gas Injection (Secondary) | Utilizes gases (e.g., natural gas, CO2) to transport oil towards the wellbore. | Offshore and onshore fields | The complex infrastructure and gas supply worries |

| Thermal Recovery | Steam injection is used to decrease the viscosity of oil to facilitate flow. | Heavy reservoirs of oil (e.g., the tar sands) | Energy consumption is high, and environmental worries are |

| Chemical EOR (Tertiary) | Utilizes polymers, surfactants, or alkaline chemical to enhance flow. | Special reservoirs that have complex fluid properties | Expensive, sensitive to reservoir chemistry |

| CO2 Enhanced Oil Recovery (CO2-EOR) | Injects CO2 to mix oil to decrease the viscosity of the oil. | Fields that are mature in the U.S., and Middle East | It requires CO2 sourcing and storage infrastructure |

| Hydraulic Fracturing (Fracking) | Injects high-pressure liquid to break rock and let out trapped oil. | Shale formations and tight oils | Environmental impact, induced seismicity |

| Horizontal Drilling | Horizontal drilling through reservoirs improves contact with the oil-bearing rock. | Formations that are tight and have low permeability | More complicated and costly than vertical drilling |

| Multilateral Drilling | Drills several wellbores from a single borehole. | Complex reservoirs and offshore lakes | More technical and demanding, which means more risky drilling |

Key Innovative Techniques in Oil Production

1. Digital Oilfields and Real-Time Monitoring

A major and revolutionary development in the production of oil is the growth in digital oilfield technology. Through the use of sensors as well as data analytics, as well as artificial intelligence (AI), operators are able to keep track of wells in real-time and anticipate failures. They can also improve production. The systems employ algorithms that learn from machine learning to analyze huge data sets, which allows for more precise control of flow rates, pressures, and the status of equipment. As technology improves, it will allow autonomous field operations and reduce human errors.

2. Advanced Enhanced Oil Recovery (EOR)

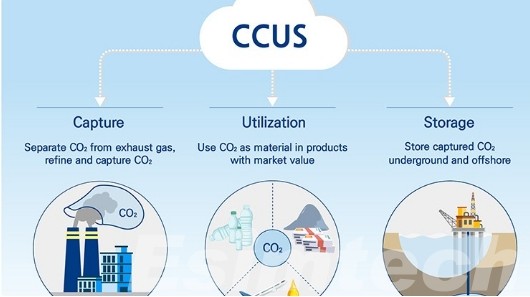

Enhanced oil recovery techniques are entering an entirely new phase. While the traditional methods like CO2 flooding and steam injection remain effective, the future strategies include technology, nanotechnology, and biotechnology. These advanced fluids are designed to alter the wettability of rocks and lower oil viscosity effectively, opening up reserves that were previously considered not economically viable.

Another promising development is the integration of EOR with carbon capture, utilization, and storage (CCUS). Injecting CO2 captured in reservoirs, the operators are able to improve oil recovery while cutting greenhouse gas emissions, thereby aligning with the global sustainability goals.

3. Intelligent Drilling Technologies

Drilling is always at the base of the production of oil, and it is getting smarter and more precise.

Here is a chart that outlines the latest innovative drilling techniques employed in the modern production of oil.

| Drilling Technique | Description | Applications | Advantages | Limitations |

| Extended Reach Drilling (ERD) | Drill wells extend out from the drilling location both laterally and vertically. | Remote and offshore fields | Accesses difficult-to-access reserves that have fewer surface locations | It requires advanced planning and equipment |

| Managed Pressure Drilling (MPD) | It precisely regulates annular pressure to stop injury to the formation and kicks. | Formations of high-pressure, narrow-margin | Increases safety, allows drilling in difficult conditions | It requires specialized equipment and instruction |

| Rotary Steerable Systems (RSS) | Utilizes downhole tools to direct the drill bit and not stop the drill bit’s rotation. | Horizontal and directional drilling | Real-time control, better wellbore placement | Costs for equipment and maintenance are high. |

| Underbalanced Drilling (UBD) | Keeps pressure in the wellbore less than the formation pressure. | Formations depleted or fragile | Reduces damage to the formation, increases the efficiency of penetration | Needs precision in pressure control and special fluids |

| Coiled Tubing Drilling | Continuous tubing is used instead of drill pipe for drilling or re-entry into wells. | Re-entry, slimhole, or unbalanced drilling | More efficient mobilization, less footprint | Limits on depth and direction control |

| Laser-Assisted Drilling | Make use of high-powered lasers to break up rock ahead of the bit. | Experimental/deep hard-formings | Potential for speedier drilling and less mechanical wear | Still in the process of development, but huge energy demand |

4. Subsea and Deepwater Innovation

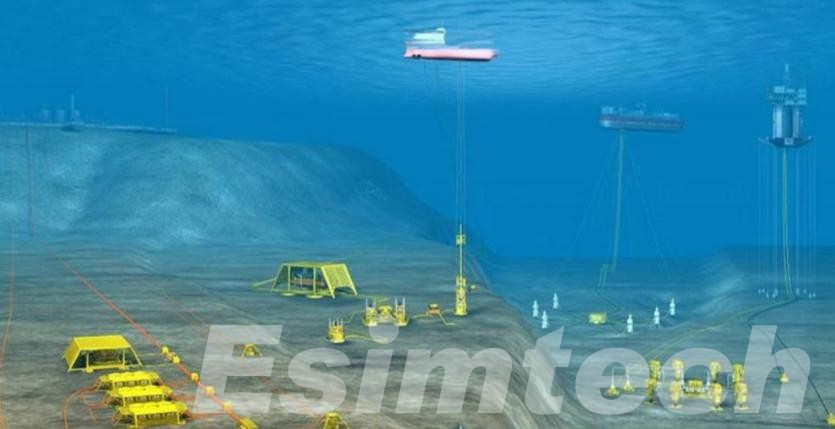

As conventional and shallow fields shrink, offshore and deepwater oil production is becoming more crucial. The subsea production systems are changing how oil is processed beneath the ocean. Pumps, compressors, as well as separators are becoming more prevalent on the ocean floor, closer to the reservoir. This increases efficiency and decreases energy consumption.

Future offshore platforms will likely become smaller and more efficient, and remote-operated. Unmanned production systems, as well as floating storage options, will be able to play an essential role in reducing the cost of production in harsh marine environments.

5. Environmentally-Conscious Techniques

Oil production in the future has to tackle environmental issues in a direct manner. Innovative technologies like zero-flaring systems and recycled water production, and drilling fluids with low emissions are becoming more prevalent. Renewable-powered field operations–utilizing solar or wind to run equipment–are also being explored to reduce carbon intensity.

Blockchain technology is currently being used to enhance the transparency of emissions monitoring as well as environmental compliance, helping businesses meet more stringent ESG (Environmental, Social, and Governance) standards.

6. Integration with Renewable Energy and AI

Oil production techniques will more often be integrated with renewable energy methods. Hybrid fields that combine solar, geothermal, or wind energy with conventional infrastructure for oil are in the process of being developed. While robotics and AI will continue to automate work-intensive tasks ranging from downhole inspections to pipeline maintenance, decreasing operational risks and costs.

These synergies do not just improve the effectiveness of oil production but can also help to create more durable and diversified energy systems.

How Simulation Technologies are Used for the Future of Oil Production

Simulation technology is playing an increasing role in determining how oil producers will operate in the coming years. Digital tools are changing the way that the industry of oil and gas industry plans and manages processes from exploration to extraction. By developing precise simulation models for physical systems, simulation allows for more accurate design, less risk, and enhanced efficiency.

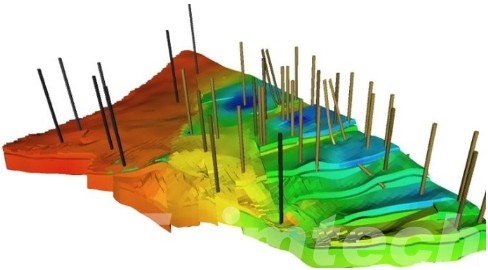

- Reservoir Simulation for Optimal Recovery

One of the oldest applications of simulation in the oil industry involves reservoir simulation. The simulations utilize geophysical, petrophysical, and fluid data to construct three-dimensional models for subsurface reservoirs. Through the use of scenarios that are run under different production techniques, engineers can predict the fluid’s behavior in terms of pressure variations, as well as the flow of gas, oil, and water in time.

Reservoir simulators aid operators in determining the most effective extraction techniques and estimating reserves with accuracy, and prolong the life of fields that are oil-based. This is especially important for deepwater and unconventional sources, in which drilling expenses are very high and errors cost a lot of money.

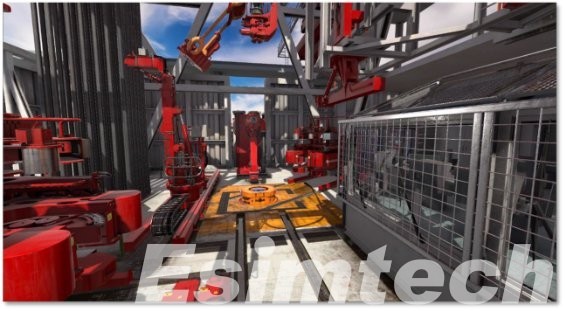

- Drilling Simulators for Safer and Smarter Operations

Drilling simulation software lets engineers and crews on rigs simulate and practice complicated drilling procedures. These software tools simulate geological formations, drilling equipment, and wellbore behavior, which allows crews to anticipate problems such as the wellbore’s instability or pressure anomalies, or damage to the formation.

Through the use of drilling simulators, companies can decrease the amount of time they waste and avoid costly accidents, and provide training to employees in a safe and secure environment. The combination of real-time data and drilling simulations can also support predictive analytics, which allows for more adaptive and flexible drilling strategies.

- Production System Modeling and Flow Simulation

Simulation is also extensively used for optimization of oil production systems. Software that simulates multiphase flow in risers, pipelines, and processing facilities can simulate temperature gradients, pressure drops, gradients, and separation of fluid effectiveness.

Through simulation of the oil and gas production systems, they are able to simulate, engineers are able to discover bottlenecks, develop designs that are more effective, as well as test how the systems react to changes, such as a decrease in flow or pressure. This will allow for more proactive maintenance planning and smoother operation of subsea and surface infrastructure.

- Enhanced Oil Recovery (EOR) Simulations

As the oil fields age, Enhanced Oil Recovery (EOR) becomes crucial. Simulation tools show how injection agents (such as CO2, steam, or other chemicals) work with reservoirs to enhance the mobility of oil. These models assist in determining the most effective EOR method for specific geochemical conditions and also determine its long-term performance.

New simulation techniques incorporate nano-EOR and smart fluids, permitting operators to play with new materials prior to applying them in the field.

- Digital Twins for Real-Time Optimization

Digital twin technology produces real-time virtual copies of oilfield assets that are physically present, including reservoirs, pipelines, and platforms. The twins are constantly refreshed with information from sensors and controls, which allows operators to track the performance, simulate scenarios, and dynamically adjust their operations.

Digital twins can help you anticipate equipment failures, improve energy usage, and maintain environmental compliance. The predictive abilities of digital twins are essential in reducing downtime as well as operational risk.

- Training and Operational Readiness

Simulation is also a crucial part of the training of personnel. Oil and gas simulators give you an immersive experience that simulates real-world conditions in the rigs, control rooms, and subsea activities. The training programs increase capabilities, increase the speed of response in emergencies, and ensure that teams are prepared to operate complex systems in a safe and effective.

- Integration with AI and Machine Learning

Future simulation technology is increasingly connected to AI as well as machine learning. These systems automatically learn from past information and enhance simulations in real-time. For instance, AI-enhanced simulations can aid in predicting wear on equipment and forecast production rates or even automate the process of making decisions for digital oilfields.

The integration of artificial intelligence is crucial in achieving autonomous field operations — an important step towards the digital revolution in the oil industry.

Summary

The future of oil production lies in the development of efficient, intelligent, and sustainable methods. Through the use of advances in digital technology, improved recovery, precise drilling, as well as environmental management, the oil and gas industry is well-positioned to face new challenges head-on. These advancements will enable oil producers to tap into more difficult-to-access resources while still ensuring compliance with ever-more stringent environmental laws. Simulation technologies are essential for the development of oil production. They help reduce uncertainty, lower costs, and increase security by allowing virtual testing and optimization across every stage of the oilfield lifecycle.