Key Strategies for Offshore Drilling in Harsh Environments

Offshore drilling has become an essential part of world energy production, and is an activity that has its challenges operating in the open sea. Difficulties in the open sea, dominated by extreme weather, the menace of ice and the hostile and corrosive nature of seawater, call for the use of engineering marvels, technological hardware and operational frameworks which are specifically designed to uphold the safety and efficiency of the undertaking, the geared operations, and the environmentally sustainable practices of the company.

Understanding Harsh Environments

Harsh offshore environments incorporate the Arctic, North Atlantic, and ultra-deepwater basins which are abundant with extreme temperatures, ice, hurricane prairies, and vicious currents. These conditions pose risk to the sea rig, the undersea cables, the manpower, and the nature that surrounds the undertaking.

Key Environmental Challenges in Offshore Drilling

| Environmental Challenge | Impact on Offshore Drilling Operations | Mitigation Considerations |

| Extreme Temperatures | Can freeze equipment, thicken drilling fluids, and affect personnel safety | Use cold-resistant equipment, specialized drilling fluids, and heated work areas |

| Ice and Icebergs | Risk of damage to platforms, risers, and subsea infrastructure | Ice management, reinforced hulls, and ice radar tracking |

| High Wind and Waves | Causes instability, operational delays, and increased safety risks | Semi-submersible or dynamically positioned rigs, real-time weather monitoring |

| Corrosive Seawater | Accelerates corrosion of metal structures, pipelines, and equipment | Use of corrosion-resistant materials, protective coatings, and regular maintenance |

| Remote Locations | Challenges in logistics, emergency response, and supply chain management | Pre-positioning of supplies, remote support systems, and contingency planning |

| Extreme Pressure and Depth | Increases stress on wellbore, blowout preventers, and subsea equipment | Advanced BOPs, pressure-managed drilling techniques, and real-time monitoring |

| Environmental Sensitivity | Potential for oil spills or ecological damage in fragile ecosystems | Strict adherence to regulations, spill prevention systems, and continuous environmental monitoring |

Operational Strategies for Offshore Drilling in Harsh Conditions

1. Rig Mobility and Flexible Platform Deployment

Moored mobile rigs and semi-submersible sh vessels can operators maintain rough-weather stability and reposition when ice or weather extremes interrupt an operation. This mobile capability affords reduced operational damage and downtime while maintaining access to remote drilling sites.

2. Risk Assessment and Contingency Planning

Robust assessment of risk is pertinent when drilling offshore in extreme environments. Some of the region’s icebergs, potential storms, and instability of the wellbore are all well-known hazards that operators prepare for with detail. Contingency planning carries protocols for the emergencies such as spills, blowouts, and equipment failures, as well as the dramatic weather conditions that can occur. These plans diffuse the risk that is associated with the personnel, the equipment, and the area of the operations.

3. Enhanced Safety Measures for Personnel

Ensuring the safety of personnel and the workers in such hostile conditions is of supreme importance. Gear for low environments, paired with emergency evacuation protocols, provide personnel with operational plans that are needed for remote, extreme weather locations, facilitating enhanced safety. Other operational plans carry well-prepared medical personnel with them.

4. Optimized Supply Chain and Logistics

Remote offshore sites are complex and require detailed planning on logistics and supply chains. The uninterrupted operation of remote sites and offshore drilling depends on advance positioning of critical materials as well as on-board fuel and spares during interruptions such as extreme weather and ice closure. In such cases, support vessels, helicopters, and satellites are coordinated along routes defined by communications.

5. Environmental Management Practices

Operational activities in areas of high ecological sensitivity require proactive environmental engineering. Preparedness with structures such as spill control and eco drilling fluids, fast and continuous environmental monitoring ensures compliance and protection of marine life. Environment Operators to stages of planning and execution toward negative ecological impacts.

6. Integration of Technology and Automation

Offshore drilling under extreme conditions has increased with automation. ROVs save divers from high-risk subsea inspections and interventions. Automated drilling systems are self-contained, monitor wellbore pressures, and variable fluid flows with systems that control events optimizing field and operation safety.

Technological Innovations in Offshore Drilling for Harsh Environments

Advanced Platform and Vessel Designs

Wind, waves, and ice movement creates instability for offshore platforms along with ice, loud and harsh weather, and water. These modern, semi-submersible rigs and dynamically positioned vessels are built to remain inbalance during harsh conditions. Stuctures on these platforms are built to last against ice and drifting ice, as well as icebergs, and keep full operations while maintaining the safety of personnel and equipment.

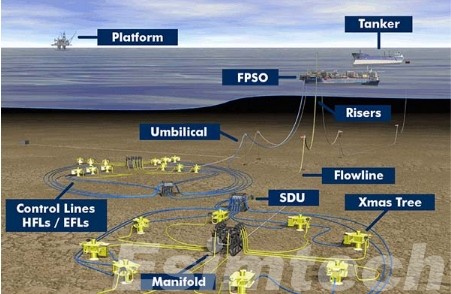

Subsea Equipment Enhancements

Systems that are better adapted to operate under low temperatures, high pressure, and underwater corrosive seawater include subsea equipment and blowout preventers. Remote monitoring and intervention provide support for wellbore control. These technologies ensure the operator will never lose control of the wellbore, even if the situation is dangerous or the area is unreachable.

Smart Drilling Fluids

Certain drilling fluids, commonly called “mud,” or “drilling mud,” are important for the stability of wellbores and the control of pressure within that wellbore. Scientific technologies mud that can form in the freezing point and can preserve the wellbore while collapsing. Drilling is also safer and much more efficient due to the new advances in the formulas used along with the more modern reserved margins.

Real-Time Monitoring and Digital Twins

Engineers rely on multiple instruments for constant monitoring in real time for their offshore drilling and digital twins allow to keep records on and monitor equipment performance, as well as well and environmental variables during the drilling to graph real time monitoring on a drilling diagram, and enable predictive maintenance for the equipment needed for the attempt. Then, a twinned system aids in complete well drilling, as well as the weather systems. Communication systems to the operators permit near real time decision making to negatives from closures during erosion, driftingstorms closed, and equipment energizing.

Ice and Weather Management Systems

Operators can very closely anticipate the onset of harsh environmental conditions, which blast drifting, and enclosed ice shifts, and get active tasks out of the sideways before the monitoring starts and the weather dips. More than predicted, this decreases. Dangerous work zones, operational silences, and the improvement of unwelcome surface vessels above a block of flowing air and ice above.

How Simulations are Used for Optimizing Offshore Drilling in Harsh Conditions

| Simulation Type | Purpose / Application | Benefits for Offshore Drilling |

| Drilling Operations and Equipment Simulation | Simulates the well platform and drilling system | Predicts equipment failures, optimizes operations and allows scenario testing without risk |

| Weather and Ice Modeling | Simulates extreme weather, ice movement, and storm conditions | Helps plan drilling schedules, vessel positioning, and ice management strategies |

| Wellbore and Pressure Modeling | Models subsurface conditions and wellbore behavior under different pressures and temperatures | Enables safe drilling in high-pressure zones, reduces kick risk, and improves well control |

| Equipment Stress and Structural Simulation | Tests rigs, risers, and subsea equipment under harsh environmental loads | Identifies weak points, improves design, and prevents structural failures |

| Drilling Fluid Dynamics Simulation | Analyzes fluid behavior under low temperatures and high pressures | Optimizes fluid properties, prevents freezing or wellbore instability |

| Emergency Response Scenario Simulation | Simulates blowouts, spills, or equipment failures | Improves contingency planning, training, and rapid decision-making |

| Supply Chain and Logistics Simulation | Models material flow, equipment transport, and resource allocation | Ensures operational continuity in remote or disrupted environments |

Environmental and Regulatory Considerations for Offshore Drilling in Harsh Environments

Generally accepted as standards, almost anywhere in the world, today. Where poles shift and land up in direct line with the oil and gas where it is deep and sensitive being sensitive, a focus on pollution inspection is greatly emphasized, as well as the action and consequence of ice and air with gentle, breathing, floating, myriad of wildlife and from above everyone. The plans shift also before big global compass points, his in the extremist positions. The operators situate around and then the governments where a block in the world.

Future Trends in Harsh Offshore Drilling

Sustainable and Environmentally Friendly Practices

There will be continued advancement in the technologies of the environment and operational within the environment. Environmentally responsible and safe drilling fluids, zero discharge drilling, and optimized spill containment systems, will be incorporated within the company. Predictive modeling technologies will be complemented with real-time ecosystem monitoring in order to anticipate changes, mitigate damage, and reinforce compliance with protective legislation on offshore drilling.

Enhanced Remote Operations and Supply Chain Integration

Harsh offshore areas are located a great distance from operational centers, which complicates the logistics of construction the center. Future operational centers will incorporate integrated supply chains and construct new operational centers to link personnel, logistics, equipment, and materials. Innovative models and advanced communications technologies and real-time, integrated predictive models of logistics will be used to ensure optimal operation in extreme isolation.

Predictive Maintenance and AI-Driven Decision Making

Artificial Intelligence (AI) systems will be increasingly used to forecast equipment failures and schedule world order systems predictive maintenance. Machine learning will optimize drilling systems to minimize operational pausing to enhance safety and absolute relibility, and offshore systems. Both reliability and cost will be marginal in harsh offshore areas.

Focus on Extreme-Environment Exploration

Drilling operations will expand into new extreme environments due to diminishing easy-to-access resources. The field of offshore drilling will expand in operational safety and protection as well as extreme control on deep-water drilling, well ice management and high pressure well control.

Summary

The operations of offshore drilling in harsh conditions is incredibly risky and is considered difficult, which means it requires the best and most innovative tools and technology to meticulously plan out and strategize the operation of the offshore drilling. Through strong infrastructure, advanced underwater technology and machinery, and observing the environment in real time, and taking care of the environment, the industry continues to explore energy resources in the most difficult locations around the globe in the safest and most efficient ways.