Multilateral Well Intervention Strategies & Workover Optimization

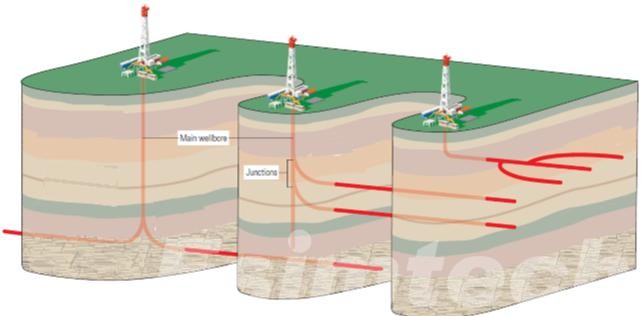

Multilateral wells are able to tap into the whole reservoir, as well as the surface area they occupy, which is very beneficial. However, the upside of the multilateral system translates into a downside quickly: well intervention and workover operations are, in terms of difficulty and risk, much more complex than in the case of common or single-lateral wells. It is likely that a badly planned intervention will lead to a very long time without the well, damage to the connections, or loss of the fruitful laterals.

The article is centered on the ways of planning and optimizing multilateral well intervention and workover operations by making use of well intervention simulators that will ultimately result in less uncertainty, cost, and production loss.

Why Multilateral Well Intervention Requires a Different Workover Strategy

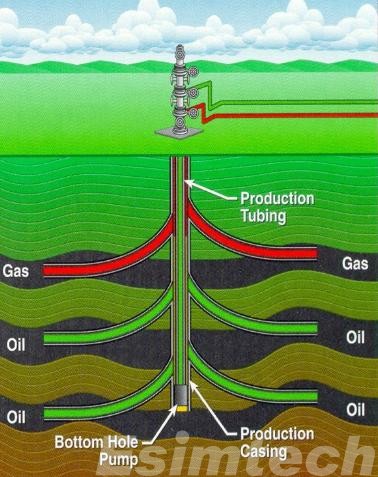

The intervention of wells using multilateral technology is totally different from the traditional workover in that the wellbore is not treated as a single flow path anymore. Rather, it is regarded as a network of laterals where each lateral is connected by a junction.

This table shows the reasons why the logic applied in standard workover is not easily applicable to multilateral wells.

| Aspect | Conventional Well | Multilateral Well |

| Flow paths | Single | Multiple, interconnected |

| Intervention impact | Local | System-wide |

| Tool access | Direct | Geometry-dependent |

| Isolation requirement | Simple | Often complex |

| Failure consequence | Limited | Can affect all laterals |

In the case of multilateral wells, an intervention designated for one of the laterals may unintentionally affect the pressure or the flow in other laterals. The integrity of junctions becomes a restriction, more so in higher TAML completions, where mechanical junctions are to withstand the loads of repeated interventions.

Therefore, workover plans have to be crafted per the specific architecture of multilateral wells rather than adapted from the experience with single-lateral wells.

Key Challenges in Multilateral Well Workover: Access, Isolation, and Production Risk

Defining a dedicated multilateral workover strategy is the first important step, but its execution is still limited by the three challenges of access, isolation, and production risk, which are closely interconnected.

- The access issue is seldom simple. To get back into a particular lateral, one has to go through the junction geometry without causing any damage to it or accidentally going into another branch. The length of the tools that can be used depends on the direction of the lateral, the completion hardware, and the method of conveyance. Even if access is possible in theory, trying to get in repeatedly raises the chance of mechanical damage and non-productive time.

- Isolation operates eminently when the intervention starts. The junction through which pressure communication is done makes it hard to isolate one lateral without affecting others. Poor isolation may cause crossflow, produce a shift in pressure in producing branches, or interfere with well control during intervention. Risks increase in wells that have different depletion and where water and gas have already broken through.

- The production risk stems from the difficulties with access and isolation cumulatively. Shutting down one lateral often changes the flow in a very unpredictable way; as a result, the total output from the well may not be increased, but rather the opposite. In some instances, freeing up a branch with an intervention intended for other branches will result in permanent loss of productivity.

The above-mentioned difficulties provide reasons why multi-lateral workovers often yield results lower than expectations when planning does not take into account the system-level behavior.

Optimizing Multilateral Well Workover Planning to Reduce Cost and Production Loss

The process of effective multilateral well workover optimization involves asking one question at the very beginning:

Is the gain in production worth the risk associated with the operation and the system?

To respond to this question, it is necessary to have information beyond just the historical performance data. Operators must also consider:

- The lateral that gives the most additional value

- If it is possible to partially intervene without the need for the entire well to be shut down

- The production disruption period and its recovery

Poor planning is the principal cause and has often led to over-intervention. In several cases, the whole well was shut down to solve the problem of an underperforming lateral, only to result in a net production decline after restart.

Optimized planning stresses the importance of:

- Current and predicted contribution as the basis of prioritization for laterals

- Intervention windows are planned in a way that minimizes damage to the reservoir is minimized

- Risk of downside quantified, not only the gain of upside

Now, planning choices change from operational judgment to economic and probabilistic assessment. That is when simulation turns out to be very important.

How Well Intervention Simulators Improve Multilateral Workover Decision-Making

Multilateral well workover decisions are often made in uncertain situations. Engineers have to choose between the tools, sequencing, and extent of intervention while being unaware of the well system’s response at all. In multilateral wells, this uncertainty is further aggravated by the behavior of the junction as well as the interaction between laterals.

The use of a well-intervention simulator significantly reduces this uncertainty as it allows engineers to assess the intervention scenarios before their actual execution. Rather than considering that the target lateral is accessible or isolated, the simulation determines the tool reachability by taking actual geometries and completion limitations into account. It also portrays the pressure communication and flow redistribution between laterals during the operations of shut-in, isolation, or re-opening.

This ability is fundamental in determining the feasibility of a partial intervention and in estimating the production impact on branches that are not the focus of the intervention. The results from the simulation aid the engineers in various ways, such as comparing different options, spotting high-risk sequences, and ruling out those with a low chance of success.

The use of trial-and-error planning is not necessary anymore as the intervention simulation makes use of predictive analysis which in return gives rise to decisions that are more defensible, reduces non-productive time, and increases the overall success of workover in multilateral wells.

Best Practices for Integrating Intervention Simulation into Multilateral Field Operations

Intervention simulation needs to be embedded in the standard planning workflow for multilateral wells to be effective, rather than being applied after operational problems have taken place. The purpose of this action is to facilitate impartial decision-making before the usage of wellbore tools.

The key best practices are as follows:

- Utilize simulation at the outset during the intervention screening process to weigh up the different scopes and sequences

- Represent lateral accessibility accurately using comprehensive completion and junction geometry

- Consider pressure communication and flow redistribution for all laterals, not only for the targeted branch

- Run several intervention scenarios to determine the risks of failure and the options with the most impact

- Incorporate post-intervention data into models to make predictions for the future more accurate

By employing these practices, a well-intervention simulator transforms into a decision-support platform rather than merely a visualization tool. It allows engineers to save on trial-and-error, lessen non-productive time, and increase the trust in the results of multilateral workover.

In case you want to build up multilateral intervention planning, our well intervention simulator is meant to facilitate these workflows and can be tested with your actual field scenarios.

Please feel free to contact us!