Real-time Downhole Data Acquisition in Oil Drilling

In the highly-stakes and complex environments of oil drilling, having timely and accurate information from deep underground is crucial to ensure safety, efficiency, and decision-making. Real-time downhole data acquisition has emerged as a transformative technology that allows operators to keep track of the drilling conditions, improving control and optimizing oil drilling performance.

What is Real-time Downhole Data Acquisition

Real-time downhole data acquisition refers to the method of capturing and transmitting data through sensors that are located within the wellbore while drilling. The sensors can measure crucial parameters like temperature and pressure, as well as vibration, drilling speed, formation characteristics, as well as fluid properties. The information is relayed to the surface control systems nearly immediately, which allows engineers to analyse the conditions and alter drilling parameters as they go.

Why Real-time Downhole Data is Important in Oil Drilling

Enhancing Drilling Efficiency

Real-time downhole data gives immediate feedback on the most important parameters like the weight of the bit, rotation speed, and the flow of mud in oil drilling operations. This allows drilling teams to modify their operations dynamically to maximize the rate of penetration and also reduce inefficient time. Instead of waiting for hours or even days for lab analysis or reports the surface engineers can make quick choices that ensure that drilling is on the right schedule, increasing efficiency overall and reducing expenses.

Improving Operational Safety

Drilling is inherently dangerous and can result in unstable wellbores, unexpected pressure surges, or even dangerous gas surges. Real-time data acquisition permits the early detection of these dangers by checking downhole pressures and vibrations, as well as formation changes. This alertness is timely and helps avoid incidents like blowouts or blocked pipe incidents, significantly improving the safety of employees and equipment.

Facilitating Better Reservoir Understanding

Access to information on petrophysical and geological processes while drilling permits operators to assess the characteristics of the formation in the course of drilling. The real-time information helps identify the reservoir zones, types of fluid and formation boundaries and enables more precise decision-making regarding well placement and casing. This information is instantly available and allows more efficient extraction methods, which results in greater hydrocarbon recovery and increased asset value.

Reducing Costs and Non-Productive Time

The ability to track conditions in the downhole continuously reduces the necessity of frequent trips to the pipe to retrieve information, thereby saving time and cash. Real-time data can also help avoid costly drilling issues by enabling quick corrective actions. A quick detection of a problem minimizes wear on equipment, stops damage to the wellbore, and cut the time between repairs and costs, resulting in substantial cost savings during the drilling process.

Supporting Advanced Analytics and Automation

Real-time data streams are the basis for the application of artificial intelligence and machine-learning tools to drill operations. These tools analyze large data sets to identify issues, enhance parameters, and automate management processes. Without real-time information, advanced analytics are not possible, which would limit the possibilities for better and more automated drilling equipment.

Enabling Responsive Decision-Making

In drilling environments that are fast-moving, delays in access to data can result in missed opportunities and costly mistakes. Data that is real-time data allows managers and engineers to respond immediately to the changing conditions in the downhole, increasing the quality of decision-making and speed. This flexibility is crucial for maintaining control over operations and adjusting to unexpected problems.

Key Technologies Enabling Real-time Downhole Data Acquisition in Oil Drilling

The success of real-time downhole data acquisition in oil drilling relies on a combination of cutting-edge technologies working seamlessly together.

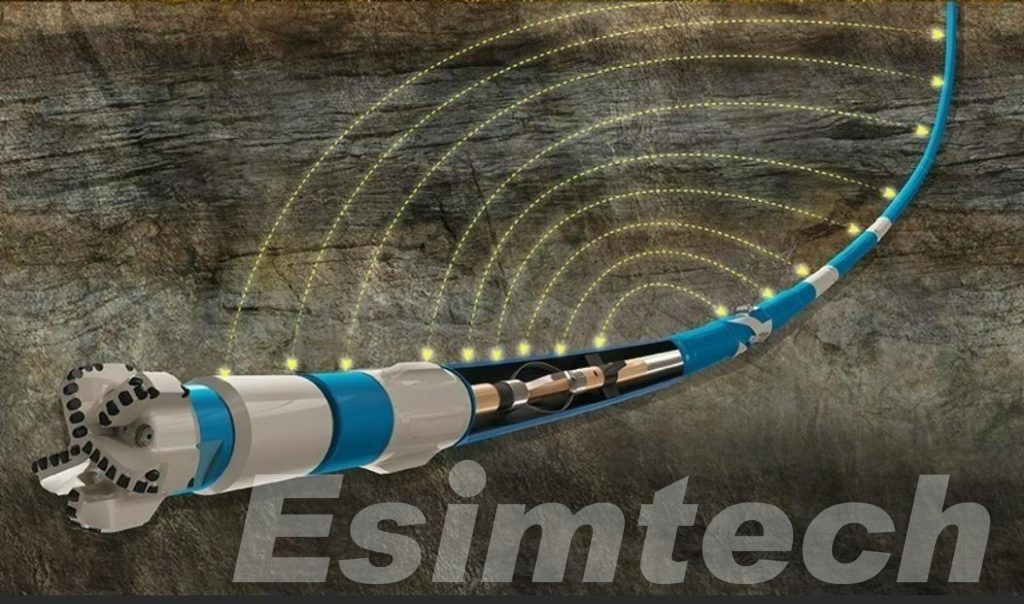

1. Measurement While Drilling (MWD) Tools

The Measurement While Drilling (MWD) tools are essential to downhole data acquisition in real-time. They are installed within the drill string. MWD tools collect directional information such as inclination of the wellbore or azimuth, as well as the toolface’s orientation. This information is vital to steer the drill bit precisely in the direction of the intended trajectory. MWD systems can also be used to measure drilling parameters such as temperature and pressure of mud, giving a full overview of the conditions downhole in real-time.

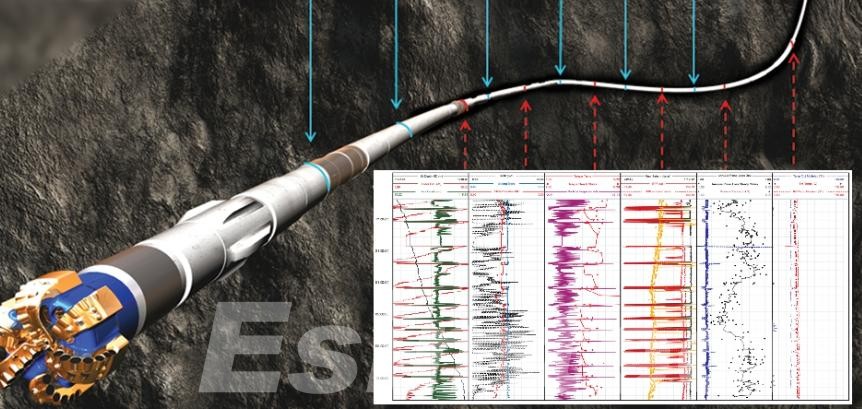

2. Logging While Drilling (LWD) Sensors

Logging While Drilling (LWD) adds value to MWD by recording geophysical and petrophysical data that is derived in the forms encountered while drilling. LWD sensors are able to measure parameters such as gamma-ray emissions, resistivity porosity, resistance, and formation density. These measurements aid in determining reservoir characteristics while drilling is still in progress, making the make informed decisions regarding well placement and the time to complete it without delay.

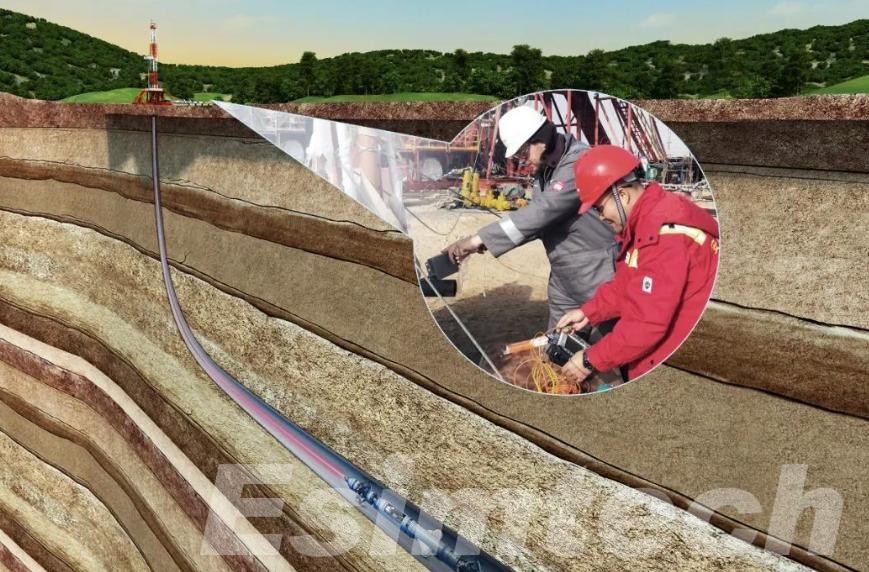

3. Telemetry and Data Transmission Systems

One of the major challenges in the field of real-time deep-hole information acquisition involves sending information from deep below to the surface quickly and consistently. Telemetry systems can provide this crucial communication connection. Traditional mud pulse technology makes use of pressure pulses sent through drilling fluids to transmit information to the surface; however, its bandwidth is limited. Electromagnetic Telemetry transmits signals across the formation, but is more dependent on environmental conditions. Recent developments include the wired drill pipe technology, which integrates electrical conductors into the pipe itself that allowing high-speed and broadband data transmission that can support larger data sets and more efficient communication.

4. Downhole Sensors and Electronics

The durability of downhole sensors that can withstand extreme conditions is essential for enabling real-time data acquisition. These sensors have to function with confidence with high temperatures, pressures, and conditions that are found within the wellbore. The advancements in miniaturization, materials technology, and durable electronics have produced sensors that can provide precise measurements for extended periods of time and ensure constant data flow without the need for frequent tool retrieval.

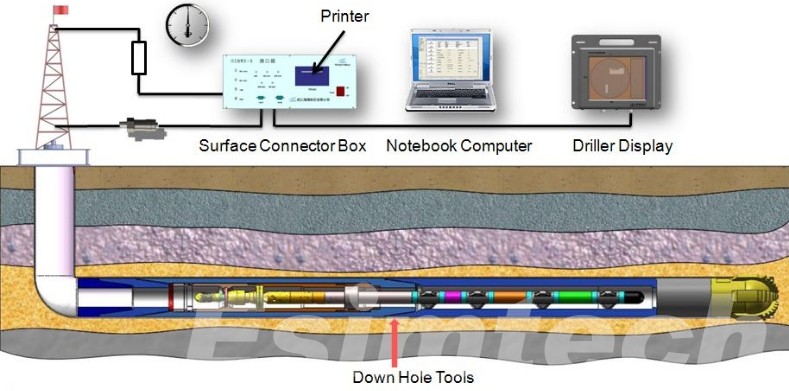

5. Surface Data Acquisition and Processing Systems

When data from the downhole reaches the surface, sophisticated data acquisition systems gather, analyze, process, and display the information in real-time. These platforms offer operators an easy-to-use interface to observe drilling parameters, analyze the formation data, and get notifications on the most critical conditions. Integration with sophisticated machine learning and analytics can further improve the capability to comprehend complex data sets and provide useful insights during drilling operations.

6. Power Supply and Energy Management Technologies

Continuous operation of downhole sensors and telemetry systems requires reliable sources of power. Technology for batteries has improved to offer durable, high-capacity energy that is small sizes that are suitable for downhole equipment. Furthermore, certain systems employ techniques for harvesting energy that harness the vibrations or thermal gradients inside the wellbore, in order to boost battery power and increase operating life.

How Simulations are Used for Real-time Downhole Data Acquisition in Oil Drilling

The simulations are essential to maximize the benefits of real-time downhole data acquisition in oil drilling. They provide deeper insights, predictive foresight, and training capabilities. Downhole simulation technologies transform raw data into actionable knowledge.

Enhancing Data Interpretation

Simulations play a vital function in the interpretation of the intricate and massive amount of data received in real-time from sensors in the downhole. Through the creation of digital models for the bore as well as surrounding formations, experts can more clearly understand the significance of sensors’ signals. Simulations can help distinguish between normal drilling patterns and irregularities like formation changes, wear and tear, or imminent failures, which allows for more accurate and prompt decision-making.

Predictive Modeling for Drilling Optimization

By using real-time data for input, drilling simulation systems can forecast what the behavior will be in the coming years of drill parameters under a variety of conditions. Predictive models study factors such as wear on the drill bit as well as torque and vibration to predict potential issues prior to their occurrence. This lets operators be proactive in adjusting the parameters of drilling to avoid costly problems such as a stuck pipe or equipment damage, increasing the efficiency and safety of.

Real-time Wellbore Stability Analysis

Simulations can be used to test the durability of the wellbore throughout drilling. Through the integration of real-time measurements of pressure, stress, and characteristics of formation, the models can pinpoint areas that could collapse or fracture. This information helps make decisions about the weight of mud and drilling speeds to keep wellbore integrity and to prevent wasted time.

Training and Scenario Testing

Beyond the operational aspect, drilling simulation training platforms offer an environment that is safe for training personnel in interpreting live downhole data and reacting to different drilling conditions. Engineers can use modeling scenarios to explore the impact of changing parameters, assisting in the development of the best strategies and contingency plans in advance of having similar scenarios on the job.

Integration with Artificial Intelligence

Modern simulation tools incorporate machine learning and artificial intelligence algorithms that draw lessons from both real-time and historical data. The intelligent systems continue to improve their accuracy in predicting and their ability to detect anomalies, increasing the value of downhole data collection in real-time and making semi-autonomous or self-contained drilling.

Challenges and Future Solutions for Real-Time Downhole Data Acquisition in Oil Drilling

| Challenges | Description | Future Solutions |

| Harsh Downhole Environment | Extreme temperature, high pressures, and corrosion-causing fluids can affect sensors. | High-temp electronics, as well as resistant to corrosion. |

| Limited Data Transmission Bandwidth | The data rate is slow with traditional mud pulse data telemetry | Conductors of electrical energy are integrated into the drill pipe to speed up secure data transfer |

| Data Overload and Complexity | Massive volumes of data are difficult to process in real-time | Data filtering automation and prescriptive analysis |

| Power Supply Constraints | Limited battery life restricts sensor operation duration | Utilizing the energy from downholes and creating batteries with a longer lifespan |

| Signal Attenuation and Noise | Noise and signal loss in underground data transmission | More efficient algorithms and more powerful equipment to improve the quality of data |

| Cost and Equipment Durability | Risk of Equipment Failure | Making tools that are easier to maintain, durable, and long-lasting, that have lower operational costs |

Summary

Real-time downhole data acquisition has become a key element of modern oil drilling operations. By providing insight into downhole conditions, it empowers operators to drill safer, faster, and more efficiently while maximizing reservoir value. As technology advances, the use of more advanced sensors, faster communication methods, and intelligent analysis will further transform oil drilling into an even more precise and controlled process.