Shale Oil Drilling vs Conventional Drilling: Key Differences

Shale oil drilling and conventional drilling are essentially different from each other in their technical and operational models, although both are aimed at crude oil production. These differences will be reflected in all stages of the project lifecycle, i.e., well design, cost structure, risk exposure, and workforce requirements. It is therefore vital for operators and service companies to have a good understanding of the differences between shale oil and conventional drilling, to choose the right development strategy and build operational capability.

The article highlights the differences between both methods by emphasizing aspects like reservoir behavior, drilling technology, operational risk, and the role of shale oil drilling simulation in training and operational readiness.

What Is Shale Oil Drilling?

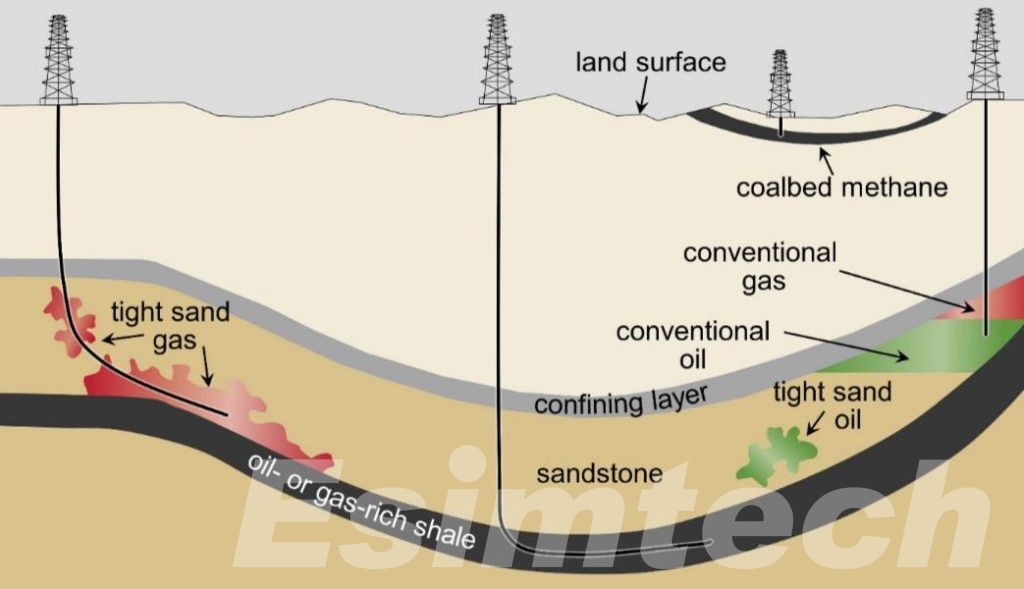

The method by which oil is extracted from the subsurface of low-permeability shale and tight rock formations, where hydrocarbons cannot flow to the wellbore naturally, is known as shale oil drilling. The better part of conventional reservoirs is that in such cases, the production of oil necessitates the use of engineered solutions to enable the extraction, as it is trapped within the formation by dense rock layers.

The process of modern-day shale oil drilling is basically the combination of horizontal drilling and hydraulic fracturing. First, the wells are drilled vertically towards the target formation. Then, the drilling is directed through the shale layer horizontally in order to make the most of the reservoir contact. Fracturing is such that it not only allows the oil to flow from the rock matrix into the well but also creates controlled networks of fractures.

In the shale oil drilling process, standardization and the use of data is very pronounced. The performance of the wells very much relies on techniques such as precise geosteering, strict pressure control, and well completion design that has been optimized. Since production decreases very fast after the initial output, the quality of the execution during the drilling and completion of the well has both a direct and a permanent effect on the recovery and the economics of the project.

What Is Conventional Drilling?

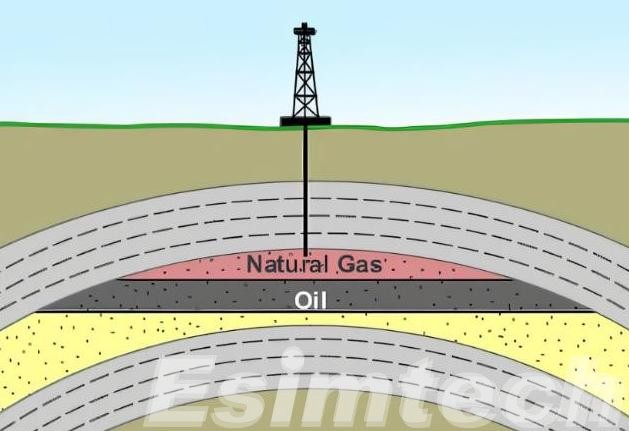

Conventional drilling methods focus on geological structures that possess naturally good permeability and porosity, for example, sandstone or carbonate. In such reservoirs, it is possible to get hydrocarbon flow to the wellhead with almost no intervention.

The majority of the conventional drilling process makes use of vertical or lightly inclined wells. Natural pressure from the reservoir drives the production, or in some cases, the production is supported by secondary recovery techniques like water injection.

To some extent, conventional drilling is more advantageous over shale oil drilling, especially concerning:

- Less complex well architecture

- Completion with less complexity

- Prolonged production life with lower decline rates.

Shale Oil Drilling vs Conventional Drilling: Reservoir Characteristics

The differences between shale oil drilling and conventional drilling are primarily defined by the reservoir characteristics. Shale oil reservoirs generally consist of fine-grained rock characterized by very low permeability. Although hydrocarbons exist, they are confined to the rock matrix, and without artificial stimulation, they cannot flow to the wellbore. So, the funding for shale reservoirs is heavily reliant on the opening of big fracture networks.

On the other hand, conventional reservoirs such as sandstones or carbonates involve a highly permeable and interconnected pore system. Oil and gas can move through the formation and come into the wellbore either by natural reservoir pressure or with little help. This results in less complicated well designs and more consistent flow behavior.

To summarize:

| Aspect | Shale Oil Drilling | Conventional Drilling |

| Permeability | Extremely low | Moderate to high |

| Hydrocarbon mobility | Restricted | Natural flow |

| Stimulation requirement | Essential | Often minimal |

| Production behavior | High initial rate, rapid decline | Stable, long-term output |

Technology Differences in Shale Oil Drilling vs Conventional Drilling

Shale oil drilling is more complex and requires more advanced technology than conventional drilling. The main technologies that differentiate them are:

- Well Construction: The method used in shale oil drilling is horizontal drilling with precise geosteering technology, while conventional drilling generally resorts to vertical wells.

- Completion Techniques: Multistage hydraulic fracturing is a crucial part of shale oil drilling, while conventional wells may not need any treatment or just a little.

- Data Management and Supervision: Shale operations rely on real-time downhole data, logging-while-drilling (LWD), and microseismic monitoring, which are the most important tools in their operations.

- Scale of Operations: Shale development usually adopts the factory-style approach with repetitive drilling programmes and standardised processes.

In contrast to drilling, technology in the latter is mainly applied to reservoir management and long-term production optimization rather than complex well construction.

Operational Risks in Shale Oil Drilling Compared to Conventional Drilling

The operational risk in shale oil drilling is higher in general because of the sophisticated well design and execution. The long horizontal sections also increase the exposure to wellbore instability, torque and drag, and cleaning the hole problems. Moreover, the narrow pressure windows make the shale wells more susceptible to mud weight errors and drilling parameter changes; therefore, the major kicks or losses would occur.

The right flawless completion process is also a must for the good lifelong performance of the shale wells. The wrong things during multistage hydraulic fracturing, such as the unsuccessful cutting off the stage or the uneven placement of the fracture, etc., can lead to lower well productivity permanently. Since steep production decline rates are always experienced by the shale wells, the early operational mistakes have a very high impact on the economic aspect of the operation.

On the other hand, the conventional drilling usually involves less complicated and more favorable reservoir conditions. While the conventional wells are subject to problems like uncertainty in the reservoir or water breakthrough, they usually give more time for corrective action and long-term optimization, which eventually leads to lower execution risk overall.

Shale Oil Drilling Simulation for Training and Operational Readiness

Shale oil drilling simulation is a very important part of the unconventional operations training, where speed and precision in the execution are the two main operators’ qualities. The interrelation between horizontal wellbores stretching to thousands of meters, tight pressure boundaries (pp), and multi-stage completions altogether makes the whole process highly complicated and does not admit any human mistakes. Simulation in the training process is the way for the teams to acquire the necessary competence.

Some of the main applications of the shale oil drilling simulation in training are:

- Well trajectory planning and geosteering decision-making

- Pressure management and control in horizontal wells

- Reacting to dysfunctions and equipment failure in drilling

- Drilling, directional, and mud logging teams’ coordination

Shale operations are, compared to normal drilling, a situation where they need higher fidelity models and faster decisions. The right simulation of shale oil drilling allows the creation of training standards that can be repeated, the improvement of the crew’s response during abnormal situations, and the reduction of non-productive time.

Simulation, when added to the training put up in a systematic way, giving rise to operational readiness and uniformity of performance during large-scale shale drilling campaigns.