The Rise of Integrated Well Intervention Solutions: Optimizing Oil and Gas Asset Performance

The efficient management of well assets is critical for sustaining production levels and maximizing returns on investment in the Oil and Gas Industry. Integrated well intervention solutions have emerged as a comprehensive approach to enhancing the performance and longevity of oil and gas wells. By combining various technologies, tools, and strategies, these solutions offer operators a holistic framework for addressing well challenges, optimizing production, and minimizing operational downtime. This article explores the significance, components, and benefits of integrated well intervention solutions in revolutionizing oil and gas operations.

The Significance of Integrated Well Intervention Solutions

Integrated well intervention solutions encompass a holistic approach to well management, combining various techniques and technologies to enhance productivity and extend the life of oil and gas wells. Unlike traditional piecemeal approaches, which often involve multiple service providers and disjointed processes, integrated solutions streamline operations, minimize downtime, and maximize returns on investment.

Components of Integrated Well Intervention Solutions

1. Data Acquisition and Monitoring Systems

- Downhole Sensors and Gauges: Deployed in the wellbore to measure parameters such as pressure, temperature, flow rates, fluid composition, and casing integrity.

- Surface Data Acquisition Systems: Collect real-time data from wellhead equipment, production facilities, and remote monitoring stations to monitor production performance and detect anomalies.

- Telemetry and Communication Systems: Transmit data from downhole sensors to surface control centers and remote monitoring facilities using wired or wireless communication networks.

2. Data Analysis and Decision Support Tools

- Data Analytics Software: Utilize advanced algorithms and machine learning techniques to analyze large volumes of data, identify patterns, trends, and anomalies, and generate actionable insights for optimizing well performance.

- Decision Support Systems: Provide operators with real-time recommendations and decision support tools based on data analytics, reservoir modeling, and production optimization algorithms.

3. Well Integrity Assessment and Management Tools

- Casing and Tubing Inspection Tools: Use electromagnetic, ultrasonic, or visual inspection methods to assess the integrity of well casing, tubing, and completion equipment.

- Cement Evaluation Tools: Assess the quality and integrity of cement bonds between casing and formation to prevent gas migration, water intrusion, and casing collapse.

- Corrosion Monitoring Systems: Detect and monitor corrosion rates in downhole and surface equipment using electrochemical sensors, ultrasonic thickness gauges, or corrosion coupons.

4. Production Enhancement Technologies

- Artificial Lift Systems: Include electric submersible pumps (ESP), gas lift systems, rod pumps, and hydraulic pumping units to enhance fluid production rates and lift efficiency.

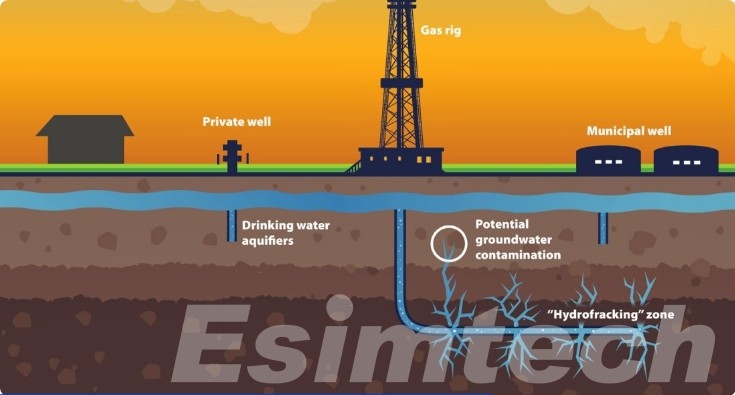

- Stimulation Techniques: Utilize hydraulic fracturing (fracking), matrix acidizing, acid fracturing, and other techniques to increase reservoir permeability and stimulate hydrocarbon production.

- Chemical Injection Systems: Inject chemicals such as corrosion inhibitors, scale inhibitors, demulsifiers, and surfactants into the wellbore to mitigate production challenges and improve fluid flow properties.

4. Remote Monitoring and Control Systems

- SCADA (Supervisory Control and Data Acquisition) Systems: Monitor and control wellhead equipment, production parameters, and safety systems from centralized control rooms or remote monitoring facilities.

- Remote Operating Systems: Enable operators to remotely operate valves, chokes, and other production equipment using actuators, hydraulic systems, or electric motors.

5. Well Intervention Equipment and Services

- Wireline Services: Provide well intervention services such as logging, perforating, mechanical interventions, and plug and abandonment operations using wireline tools and equipment.

- Coiled Tubing Services: Perform various interventions such as cleanouts, acid treatments, milling, and sand control using coiled tubing units equipped with surface control systems and downhole tools.

- Snubbing and Workover Services: Conduct more complex well interventions such as workovers, completions, and remedial operations using snubbing units, workover rigs, and associated equipment.

6. Environmental and Safety Systems

- Emissions Monitoring and Control Systems: Monitor and control greenhouse gas emissions, volatile organic compounds (VOCs), and other air pollutants from production facilities using emission monitoring sensors, scrubbers, and flare systems.

- Safety Instrumented Systems (SIS): Implement safety systems such as emergency shutdown systems (ESD), fire and gas detection systems, and blowout preventers (BOPs) to mitigate risks and prevent catastrophic events.

Benefits of Integrated Well Intervention Solutions

1. Optimized Production Efficiency

- By combining various intervention techniques, data analytics, and monitoring systems, integrated solutions enable operators to optimize production efficiency and maximize hydrocarbon recovery from reservoirs.

- Real-time data analysis and decision support tools allow for proactive identification of production bottlenecks, optimization of production parameters, and implementation of targeted interventions to enhance well performance.

2. Minimized Downtime and Operational Risks

- Integrated well intervention solutions streamline well intervention activities, minimize downtime, and reduce the risk of unplanned outages, production losses, and safety incidents.

- Proactive monitoring, predictive analytics, and remote control capabilities enable operators to detect and mitigate potential issues before they escalate, ensuring uninterrupted production and minimizing operational risks.

3. Improved Reservoir Management

- By leveraging advanced data analytics, reservoir modeling, and production optimization techniques, integrated solutions facilitate better reservoir management.

- Operators can gain valuable insights into reservoir behavior, optimize well placement and completion designs, and implement tailored production strategies to maximize hydrocarbon recovery and extend the economic life of reservoirs.

4. Enhanced Environmental Performance

- Integrated well intervention solutions prioritize environmental stewardship by minimizing the environmental footprint of intervention activities and adopting sustainable practices.

- By reducing emissions, minimizing waste generation, and implementing best-in-class environmental management practices, operators can enhance environmental performance and comply with regulatory requirements.

5. Cost Savings and Increased ROI

- Integrated well intervention solutions offer cost-effective alternatives to traditional piecemeal approaches by optimizing resource utilization, reducing operational expenses, and maximizing asset value.

- By minimizing downtime, optimizing production rates, and extending the productive life of wells, operators can achieve significant cost savings and increase return on investment (ROI) over the lifecycle of oil and gas assets.

6. Enhanced Safety and Regulatory Compliance

- Well intervention solutions prioritize safety and regulatory compliance by implementing robust risk management protocols, adhering to industry best practices, and maintaining strict quality control standards.

- By enhancing safety performance, reducing the risk of incidents, and ensuring compliance with regulatory requirements, operators can protect personnel, assets, and the environment, while fostering trust and confidence among stakeholders.

7. Operational Flexibility and Adaptability

- Well Intervention techniques offer operators greater operational flexibility and adaptability to changing reservoir conditions, market dynamics, and regulatory requirements.

- Advanced data analytics, remote monitoring, and control capabilities enable operators to adjust production parameters, optimize well performance, and implement adaptive strategies in response to evolving operational challenges and opportunities.

Applications of Integrated Well Intervention Solutions

1. Conventional and Unconventional Oil and Gas Production

- Integrated well intervention solutions are applicable to both conventional and unconventional oil and gas production operations, including onshore and offshore fields, shale plays, tight reservoirs, and heavy oil formations.

- These solutions are deployed to enhance production efficiency, optimize reservoir drainage, and extend the economic life of well assets through targeted intervention programs and production optimization strategies.

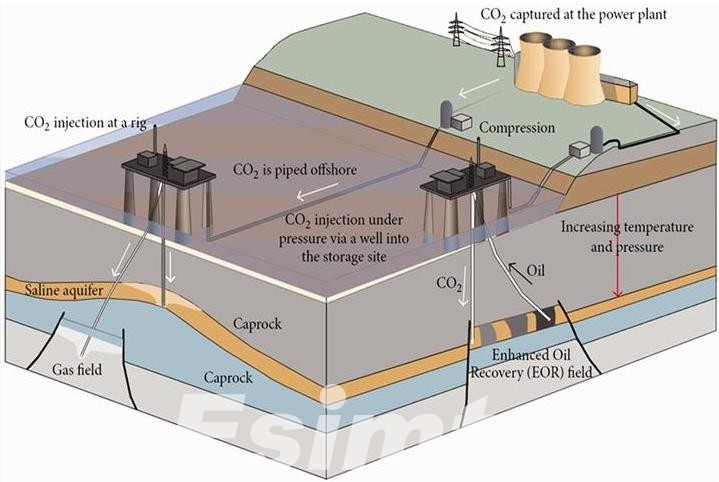

- Mature Field Revitalization

- Well intervention solutions are utilized to revitalize mature oil and gas fields by optimizing production from existing wells, enhancing reservoir recovery, and implementing enhanced oil recovery (EOR) techniques.

- By deploying advanced data analytics, well integrity assessment, and production enhancement technologies, operators can mitigate production decline, increase hydrocarbon reserves, and extend the productive life of mature fields.

3. Drilling and Completion Operations

- Integrated well intervention solutions support drilling and completion operations by providing real-time data, insights, and intervention capabilities to optimize wellbore construction, completion designs, and drilling parameters.

- Operators can leverage advanced monitoring systems, data analytics, and decision support tools to optimize drilling efficiency, minimize formation damage, and ensure the integrity and performance of wellbore tubulars and completion equipment.

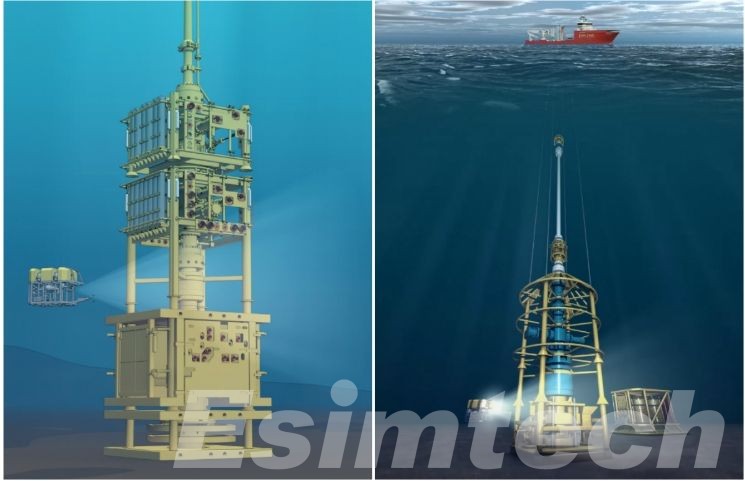

4. Subsea and Deepwater Operations

- Well intervention techniques are deployed in subsea and deepwater operations to monitor and control well performance, mitigate operational risks, and optimize production efficiency in challenging offshore environments.

- Remote monitoring, intervention, and control systems enable operators to remotely monitor subsea equipment, adjust production parameters, and troubleshoot issues in real time, minimizing the need for costly and time-consuming intervention activities.

5. Well Integrity Management

- Integrated solutions encompass comprehensive well integrity assessment and management programs to ensure the structural integrity and reliability of well assets throughout their lifecycle.

- Operators can leverage advanced inspection tools, data analytics, and risk-based integrity management approaches to identify and address integrity issues such as corrosion, leaks, casing failures, and mechanical integrity problems.

6. Enhanced Oil Recovery (EOR) and Reservoir Management

- Well intervention techniques play a crucial role in enhanced oil recovery (EOR) and reservoir management by optimizing injection strategies, monitoring reservoir performance, and implementing tailored production enhancement techniques.

- Operators can deploy advanced reservoir modeling, data analytics, and production optimization tools to maximize hydrocarbon recovery, minimize production costs, and achieve optimal reservoir management outcomes.

7. Asset Decommissioning and Abandonment

- Integrated well intervention techniques are utilized in asset decommissioning and abandonment activities to ensure the safe, cost-effective, and environmentally responsible closure of oil and gas wells and facilities.

- Operators can leverage advanced well intervention techniques, well plug and abandonment (P&A) technologies, and environmental remediation strategies to mitigate risks, comply with regulatory requirements, and minimize the long-term liabilities associated with decommissioned assets.

How Simulation Technology is Used in Integrated Well Intervention Solutions

Simulation technology plays a crucial role in integrated well intervention solutions by enabling operators to model, simulate, and optimize various aspects of well performance, reservoir behavior, and intervention operations.

1. Reservoir Simulation

- Reservoir simulation software is used to model the behavior of subsurface reservoirs, including fluid flow, pressure distribution, and hydrocarbon production.

- Operators can simulate different reservoir scenarios, evaluate production strategies, and optimize well placement and completion designs to maximize hydrocarbon recovery and reservoir performance.

- Reservoir simulation helps operators understand reservoir dynamics, predict production profiles, and make informed decisions about well intervention activities, such as hydraulic fracturing, matrix stimulation, and water flooding.

2. Wellbore Hydraulics Simulation

- Wellbore hydraulics simulation software is used to model fluid flow dynamics within the wellbore, including pressure losses, flow rates, and fluid properties.

- Operators can simulate different wellbore configurations, production scenarios, and intervention operations to optimize production rates, minimize formation damage, and ensure well integrity.

- Wellbore hydraulics simulation helps operators design effective artificial lift systems, optimize production tubing sizes, and diagnose flow-related issues such as gas locking, liquid loading, and sand production.

3. Drilling and Completion Simulation

- Drilling and completion simulation software is used to model the drilling process, wellbore trajectory, casing design, and completion techniques.

- Drilling simulators can simulate different drilling parameters, formation characteristics, and completion scenarios to optimize drilling efficiency, reduce drilling risks, and ensure wellbore integrity.

- Drilling and completion simulation helps operators design cost-effective wellbore trajectories, select appropriate casing and completion equipment, and mitigate drilling-related challenges such as wellbore instability, lost circulation, and stuck pipe incidents.

4. Production System Simulation

- Oil and gad production system simulation is used to model the entire production system, including surface facilities, wellhead equipment, flowlines, and processing units.

- Operators can simulate different production scenarios, equipment configurations, and operating conditions to optimize production efficiency, minimize operational risks, and maximize asset value.

- Production system simulation helps operators identify production bottlenecks, optimize facility designs, and evaluate the impact of production enhancement techniques such as artificial lift systems, gas lift optimization, and water injection.

5. Well Intervention Planning and Optimization

- Simulation technology is used to plan and optimize well intervention activities such as workovers, stimulations, and well integrity assessments.

- Operators can simulate different intervention techniques, operational scenarios, and downhole conditions to optimize intervention designs, reduce operational risks, and improve intervention efficiency.

- Well intervention simulation helps operators plan intervention programs, estimate intervention costs, and evaluate the effectiveness of intervention strategies before deployment in the field.

6. Training and Decision Support

- Simulation technology is used for training operators, engineers, and technicians on well intervention procedures, equipment operation, and emergency response protocols.

- Operators can use interactive simulators and virtual reality (VR) training modules to simulate realistic well intervention scenarios, practice decision-making under different conditions, and enhance competency and preparedness.

- Simulation-based training helps operators improve safety performance, reduce human errors, and ensure personnel readiness for well intervention operations in the field.

Conclusion

Integrated well intervention solutions represent a strategic approach to optimizing oil and gas asset performance, maximizing production efficiency, and minimizing operational risks. By integrating advanced technologies, data analytics, and best practices, these solutions enable operators to proactively manage well assets, enhance reservoir recovery, and achieve operational excellence across diverse operating environments.