Cost-effective Strategies for Well Intervention

The oil and gas industry operators are under constant pressure to maximize production while minimizing operating expenses. As fields that are mature, getting older, production decreases, well intervention is crucial to restore and enhance productivity. But traditional well interventions can be expensive and difficult to implement. Implementing cost-effective strategies for well intervention is essential to ensure the profitability of the business without sacrificing safety and efficiency.

Understanding Well Intervention

Well intervention is any action performed on a well prior to or following its productive lifespan to determine the cause of problems, restore flow or boost the performance. These interventions could vary from simple wireline logging, to more complicated coiled tubing or snubbing procedures. Effective well interventions for wells are designed to increase the recovery of wells, prolong their life and decrease downtime with efficient planning, integration of technology and efficient execution.

Key Principles of Cost-effective Well Intervention

In order to achieve efficiency in costs, well Intervention programs that work well should be focused on a blend with selection of technology and operational excellence.

1. Comprehensive Well Diagnostics and Monitoring

The fundamentals of any effective and cost-effective approach to intervention is understanding the performance of the well and its condition before deciding to take actions. Continuous monitoring with devices for downhole monitoring, such as pressure gauges and production logging tools gives live insights into the well’s behavior. The data-driven diagnostics allow operators to identify issues earlier, such as mechanical breakdowns, formation damage or decline in production, allowing targeted and prompt interventions. Digital twins and predictive analytics help further enhance this process by predicting potential problems and optimizing the timing of interventions in order to avoid costly and unplanned shutdowns.

2. Selection of the Appropriate Intervention Method

The right choice of well intervention based upon the condition of the well, its objectives and infrastructure that is vital to control expenses.

Here’s a simple and clear chart that outlines the various types of cost-effective well intervention techniques.

| Type of Intervention Technique | Description | Key Advantages | Typical Applications |

| Slickline Operations | Utilization of a thin, non-electrical pipe to carry out mechanical tasks within the wellbore, such as setting plugs, removing valves and using gauges. | Low-cost, fast deployment, minimal equipment required. | Routine maintenance such as valve operation and setting plugs or pulling them. |

| Electric Wireline Operations | Make use of the power of an electrical cable bring equipment into the well to facilitate recording, data acquisition, or for mechanical manipulation. | Provides real-time data, enables precise depth control, cost-effective for diagnostics. | Perforation, well logging, data collection and deployment of tools. |

| Coiled Tubing Operations | It is made up of continuous tubing that is attached to reels, which allows flow of liquid while performing operations under pressure. | Flexibility, lower time to rig up, and can be operated without destroying the well. | Well cleaning and nitrogen lifting, acid stimulation and removal of sand. |

| Hydraulic Workover Units (HWU) | Small, self-contained units that are able to perform major interventions with no drilling rig. | Cost of mobilization is lower than rigs, able of more complex operations. | Repair of the tubing or fishing operation. |

| Through-tubing Interventions | Operation is conducted without taking off the production tubing by employing specialized tools for small diameters. | Minimal downtime, avoids expensive tubing pull, cost-efficient. | Perforation or stimulation, fishing and plug insertion via tubing. |

| Chemical Stimulation | Utilizes chemical compounds such as solvents or acids in order to dissolve scale, clear obstructions, or increase permeability. | Non-mechanical, quick deployment, improves flow efficiency. | Removal of scales, acidizing paraffin treatment, as well as near-wellbore cleaning. |

| Nitrogen Lift Operations | Nitrogen gas injection to lower hydrostatic pressure and remove fluids from the bore. | Portable installation allows for the restoration of flow in wells that are not functioning Cost-effective for temporary recovery. | Cleanouts, unloading of wells, and restarting shut-in wells. |

| Robotic and Remote-operated Tools | Remotely controlled or automated devices for precise intervention particularly in hazardous or offshore environments. | Increased safety, less personnel, suitable for hard-to-access wells. | Light interventions offshore and data logging operations. |

3. Integration of Digital and Automated Technologies

Digitalization is revolutionizing the economy of well-intervention. Automated intervention remote monitoring, remote monitoring and artificial intelligence enables immediate decision-making as well as operational precision. Cloud-based analytics platforms allow teams to assess the performance of their teams remotely and test various interventions prior to deployment. Automated systems, like robot wireline tools, or self-contained coiled tubing units limit human involvement, lower the cost of labor and improve security in high-risk areas. The digitalization of well interventions does not just reduce operational costs but also increases the reliability and consistency of performance.

4. Streamlined Operations and Standardized Procedures

The efficiency of execution directly affects the efficiency of well interventions. Standardizing procedures across several fields or wells helps to reduce redundancies and operational mistakes. Intervention teams with multiple skills capable of handling a variety of tasks can improve workflows and speed up changeover times for crews. Standardization also makes training easier and documentation procedures, which ensures better coordination and speedier turnaround. Additionally, scheduling interventions within clusters of wells that are close together reduces the cost of mobilization of equipment and boosts the utilization of assets This is especially advantageous in remote or offshore field operations.

5. Preventive and Predictive Maintenance Approach

Instead of relying only on corrective actions, adopting the proactive and predictive maintenance approach drastically reduces the long-term cost. By studying trends in production and data on equipment performance operators can anticipate the moment when intervention is needed and intervene before a malfunction occurs. This reduces the chance of unplanned downtime and helps avoid costly repairs later. Prevention of maintenance also increases the longevity of assets, allowing companies to prolong the life of wells as wells are able to delay the cost of abandonment.

6. Effective Use of Chemical and Through-tubing Solutions

Through-tubing and chemical treatments offer low-cost alternatives to mechanical techniques. Chemical stimulation techniques, like scaling dissolution, acidizing and removal of paraffin can increase productivity without the requirement for massive mobilization of equipment. Through-tubing solutions allow operators to complete fishing or perforation tasks without dragging the tubing string. This drastically cuts down on time and costs. These methods that are minimally disruptive are particularly beneficial for maintaining the continuity of production in marginal or mature wells.

7. Collaboration and Knowledge Sharing

Collaboration across disciplines between reservoir engineers production specialists, engineers, and intervention teams can lead to more efficient and informed decisions. Sharing the best practices across projects will ensure constant improvement and advancement in interventions. Furthermore, collaborations with technology companies can provide access to cutting-edge tools and knowledge without massive capital investment, making interventions cost-effective and affordable.

Effective Well Intervention Planning for Cost Savings

A well intervention program that is well-organized ensures that resources are utilized efficiently, downtime is reduced and the return on investment is maximized. Effective planning requires a combination of assessment and analysis, risk management and strategic coordination which will result in significant cost savings.

1. Comprehensive Well Evaluation Before Intervention

Before a new intervention is made an in-depth evaluation of the performance of the well, its reliability, and history of production is crucial. This includes looking at the well logs, trends in production as well as pressure data as well as previous records of intervention. Knowing the cause behind the decline in performance allows engineers to identify the best approach to intervention and prevent unnecessary operations. Diagnostics that are early using data in real time as well as predictive tools permit problems to be tackled early, which can avoid costly repair and shutdowns.

2. Integration of Multidisciplinary Expertise

A successful plan for intervention in a well requires collaboration between geologists, the engineers of reservoirs, producers and teams for well intervention. Through bringing together expertise from different disciplines operators can develop more efficient interventions that match the reservoir’s behavior and production objectives. This multidisciplinary approach ensures both economic feasibility as well as technical effectiveness are considered, thus reducing the chance of having unproductive or redundant operations.

3. Economic Assessment and Prioritization

Not every intervention delivers equal value. A thorough cost-benefit analysis can help you select operations and wells that provide the most ROI. This analysis should consider direct costs such as labor, equipment, and materials, as well as indirect costs like production disruptions. Simulation models can be used to forecast the way that different intervention strategies can affect production and profitability which allows managers to prioritize budgets and concentrate on the most financially viable options.

4. Optimizing Logistics and Scheduling

Logistics play an important aspect in determining the total costs of intervention especially in remote or off-shore areas. Effective planning requires coordination of mobilization of equipment crew assignments, equipment mobilization, and supply chain operations to minimize idle time as well as travel costs. By arranging interventions in close geographical wells allows for the sharing of mobilization and reduces transport and set-up expenses. Planning interventions for planned maintenance or production shut-downs minimizes disruptions and improves efficiency in cost.

5. Standardization and Procedure Optimization

Implementing standard intervention protocols across several fields or wells improves the consistency of operations and decreases time to complete. Standardization helps reduce errors made by humans, speeds up training and provides an efficient workflow that increases security and efficiency. Utilizing portable and modular intervention devices aids in reducing costs because these devices can be deployed faster and use less labor.

6. Leveraging Simulation Technologies for Planning and Decision-making

The integration of oil and gas simulation technologies has revolutionized well intervention planning, which enable engineers to simulate various scenarios before committing to a well intervention plan.

Here’s a clear and detailed chart explaining how well intervention simulations are used for cost savings.

| Simulation Technology | Function in Well Intervention | Cost-saving Mechanism | Practical Applications |

| Digital Twin Simulation | Creates a live-time virtual model of the well, allowing you to visualize the behavior of the well under different operational conditions. | Reduces trial-and-error by anticipating the outcome prior to field execution; reduces the amount of downtime and waste of resources. | Evaluation of intervention strategies for testing, production efficiency, and predicting the performance of equipment. |

| Reservoir Simulation Models | Models how fluids flow as well as the pressure changes that occur in reservoirs in response to intervention and during the process. | It allows for the precise design of injection or stimulation operations to avoid over-treatment, and save the cost of materials. | The design of acid stimulation, flooding with water, and gas injection plans for the best recovery. |

| Wellbore Flow Simulation | Simulation of fluid dynamics and pressure profile and temperature fluctuations within the wellbore during intervention. | Aids in optimizing the pump’s rate and properties to reduce damage caused by formation and decrease the risk of operation. | Cleanouts of coiled tubing to plan as well as nitrogen lifting and well killing processes. |

| Mechanical System Simulation | Models mechanical parts such as tubing, tools, and downhole assemblies in the presence of operating loads. | Reduces the risk of tool failure and costs resulting from damage to equipment or holes that are lost. | Validation of design tools and running simulations of coiled tubing operations. |

| Economic Simulation Tools | Combines financial and technical information to determine the cost-benefit analysis of various interventions. | Lets decision makers choose the most cost-effective solution by comparing the impact ROI. | Assessing the feasibility of interventions Prioritizing, budgeting, and evaluating the most suitable candidates. |

| Operational Sequence Simulation | Simulates the entire flow of an intervention, from the moment of mobilization until its conclusion. | Finds inefficiencies, optimizes the crew’s scheduling, and reduces the amount of non-productive time. | The planning of offshore multi-well intervention campaigns, or urgent projects. |

| Risk and Contingency Simulation | Make use of probabilistic models to determine possible operational risks and to determine mitigation strategies. | Reduces the risk of unexpected expenses by anticipating the possibility of failure and developing effective contingency plans that are cost-effective. | Assessing the reliability of equipment as well as formation instability and safety measures. |

| Training and Virtual Reality (VR) Simulators | Offers a variety of training and immersive environments for teams to learn intervention techniques. | Improves worker readiness, reducing time and expense of errors in real-world operation. | Personnel who train in slickline, wireline or coiled tubing processes prior to deployment. |

7. Proactive Risk Management and Contingency Planning

Each well operation comes with inherent risks that could cause expensive delays if they are not properly controlled. Effective planning involves conducting thorough risk assessments to determine the likelihood of problems, like the failure of equipment or formation instability or concerns regarding integrity of the well. The development of contingency plans allows for rapid responses to any unexpected issues which reduces downtime and prevents financial loss. A proactive approach to risk management does more than protect equipment and personnel, but also helps ensure operational continuity.

8. Continuous Evaluation and Post-intervention Review

Following the intervention, performing an extensive review of the performance can help determine if the goals were met within the budget. Reviewing the actual and the anticipated results can provide valuable information to improve future intervention planning. Learnings from each project aid in the continual enhancement of the operational strategy, which ensures that cost savings can be sustained throughout the course of time.

Emerging Technologies Used for Cost-effective Well Intervention

These new technologies do not just reduce the need of costly large-scale well intervention operations, but also allow instantaneous decision-making and maintenance planning.

Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and machine learning (ML) have revolutionized the way we make decisions in well intervention through the provision of predictive insights and automating. These tools analyze huge volumes of operational and production data to detect trends in performance as well as detect any anomalies and anticipate failures before they happen. AI-driven models assist in optimizing intervention time, recommend corrective actions, and automate the selection of tools by analyzing previous results. In the end, users can prevent unplanned downtime and reduce the need for unnecessary interventions and concentrate their resources on the most impactful actions.

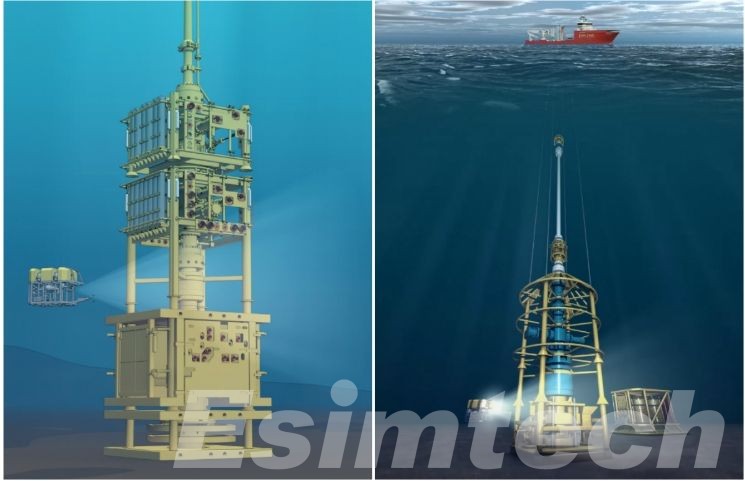

Autonomous and Robotic Intervention Systems

The use of autonomous and robotic systems has significantly improved the efficiency of operations, particularly in high-risk, offshore situations. They can carry out tasks like wireline logging, valve manipulation and mechanical repairs without the need for extensive presence of a human on site. Fully autonomous or remotely operated devices reduce the cost of labor as well as reduce safety risks and guarantee the exact execution of tasks. Additionally robots are able to operate in hazardous or restricted environments in which traditional methods of intervention could be risky or costly.

Advanced Coiled Tubing and Wireline Technologies

Recent advances in coiled tubing and wireline technology have increased their performance and versatility. Intelligent coiled tubing includes sensors in the downhole and systems for telemetry which provide live measurement of temperature, pressure and flow parameters in the course of operations. In the same way, digital wireline equipment that are equipped with automated depth correlating with data transmitting capabilities allow rapid and precise intervention. These advancements do not just reduce operating time, but also increase accuracy, which results in less cost per job.

Smart Materials and Self-healing Technologies

Materials science innovations have led to better wells and less intervention frequency. Smart materials, for instance self-healing and corrosion-resistant alloys are able to automatically close tiny cracks and repair damages caused by pressure fluctuations or chemical processes. Utilizing these advanced materials prolongs the lifespan of wells and reduces the necessity for costly remedial workovers. In addition, advanced elastomers and nanomaterials are being created to increase the endurance and flexibility of downhole equipment.

Real-time Data Analytics and Cloud-based Platforms

Real-time analytics and cloud computing have revolutionized the way that intervention data is managed and used. Through the integration of data from multiple sources, such as surfaces, sensors and production monitoring systems, operators get an entire view of their the performance of their equipment. Cloud platforms permit teams with different functions to collaborate remotely, study trends, and alter the parameters of intervention immediately. This reduces the time to respond and improves the accuracy of decisions and decreases the cost associated with data management and field surveillance.

Augmented and Virtual Reality (AR/VR) Applications

AR and VR technology is being used as effective tools to support training and operation for well intervention. Virtual reality simulators offer realistic training and simulation environments for intervention teams and reduce the requirement for costly on-site training. Augmented reality on the contrary, helps field technicians in their operations by overlaying digital information, like schematics, instructions or live data– onto real-world equipment. These immersive technologies increase efficiency, decrease errors, and decrease downtime in operations, leading to significant savings in costs.

Energy-efficient and Modular Equipment Design

Modular, compact intervention systems are replacing heavy-duty machines for many tasks. These lighter units are simpler to move, faster to put together and use fewer workers to use. Electric and energy-efficient hydraulic systems as well as drive technologies also cut down on fuel consumption and operational expenses. Modular designs’ flexibility make them suitable for remote and offshore field applications in which cost control is essential.

Summary

Cost-effective well intervention strategies are important in the current competitive energy market. By combining smart thinking along with digital innovation and a variety of technologies that are appropriate for the job, operators can sustain production and well integrity and realize significant cost savings. As the field is evolving with the introduction of automated systems, real-time analytics and environmentally friendly materials will further improve the effectiveness of well interventions and ensure continued achievement in both established as well as new areas.