How Choke Manifold Systems Work in Drilling Well Control Operations

The control of well formation pressures safely and predictably is important in drilling operations. Although the BOP serves as a barrier, true pressure control happens at the surface-through the choke manifold system. The choke manifold system enables the operator to control annular pressure and influx behavior while maintaining bottom-hole pressure stability during kick circulation. Understanding how it works and training crews to operate it effectively is essential for preventing well-control incidents and protecting both personnel and assets.

What Is a Choke Manifold System?

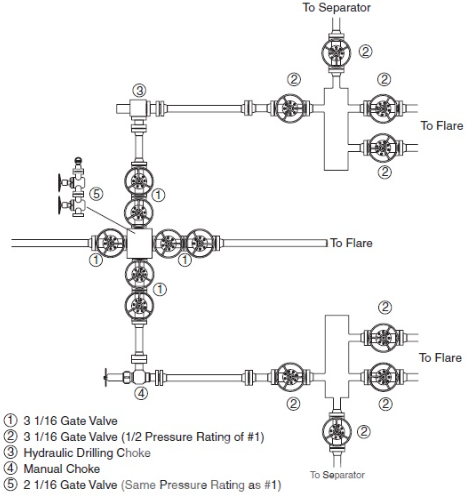

One of the surface components indispensable in well control of drilling is the choke manifold system. Situated downstream of the BOP, it serves to provide a controlled path to manage annular pressure once the well is shut in. It generally consists of manual chokes, automatic chokes, high-pressure valves, pressure gauges, crossover lines, and a control panel.

Whereas the BOP seals the well to prevent uncontrolled flow, the choke manifold system enables drilling personnel to control pressure, handle fluid returns, circulate kill mud, and safely handle gas expansion during well control operations. This is accomplished by applying backpressure on the well using precisely controlled choke openings, enabling the team to maintain the correct bottom-hole pressure throughout the kill process.

In deeper wells, HPHT environments, or gas-rich formations, the reliability and responsiveness of a choke manifold become even more critical. These wells often have rapid pressure fluctuations, and without an adequate choke manifold system for well control, the operators would not be able to stabilize the well or manage influxes safely.

Why Choke Manifolds Are Essential in Well Control?

Within well control, a choke manifold system is critical to ensure operators precisely control wellbore pressure, maintain safe bottom-hole pressure, and safely circulate kill fluids during a kick or influx event. In its absence, even with a fully functional BOP, the control of gas expansion and fluid flow at the surface would be difficult and possibly hazardous.

1. Maintaining Stable Bottom-Hole Pressure

When a kick occurs, the formation fluids enter the wellbore, raising the pressure and causing flow towards the surface. The choke manifold allows for incremental adjustments of backpressure with the intent of maintaining BHP within the safe operating window, thereby preventing the well from becoming underbalanced, which may escalate to a blowout.

2. Enable Controlled Kill Operations

The choke manifold allows operators to regulate the return flow of drilling mud and formation fluids during kill circulation. Regardless of whether a well kill is performed using the Driller’s Method or Wait and Weight Method, stable surface pressure has to be achieved to circulate heavier kill mud down the wellbore without over-pressurizing the formation or causing fluid losses.

3. Gas Expansion and Flow Variability Management

As the gas in the annulus rises to the surface, it expands rapidly and causes variations in the annular pressure. The choke manifold offers a controllable outlet for both gas and fluid, permitting the operators to absorb such fluctuations and maintain consistent well control. Gradual adjustment of the choke openings permits gas to be vented safely while the pressure at the bottom of the well is maintained constant.

4. Redundancy and Operational Flexibility

Most choke manifolds are designed with multiple chokes and parallel flow lines, providing a backup path should a valve fail or erode. This allows for continuous control under harsh conditions and a very reliable system, both for routine well-control operations and emergency ones.

Fundamentally, the choke manifold is something more than a set of valves: it is a major tool for precision pressure management, allowing safe and controlled operations in modern drilling environments.

How a Choke Manifold System Works?

Understanding how the choke manifold system works is crucial for the safe and successful well control operation. The system acts like a dynamic pressure regulator controlling the flow of drilling fluids and formation fluids from the wellbore to the surface during kick or kill operations. Its operation can be broken down into key stages:

1. Kick Detection and Well Shut-In

Once a kick is recognized as happening through flow anomalies, pit gain, or gas readings, the initial step is to shut in the well with the BOP. The choke manifold then serves as the primary means of surface pressure control when the well has been sealed, and the operator will manage the influx at the surface without over-pressuring the wellbore.

2. Shut-in Pressures

After shut-in, operators record critical surface pressures such as the shut-in drillpipe pressure, SIDPP, and shut-in casing pressure, SICP. These readings provide the baseline for subsequent choke adjustments and circulation planning such that the bottom-hole pressure remains within the safe window.

3. Annular Pressure Regulation

The basic function of the choke manifold is to provide controlled backpressure on the well:

- Opening the choke reduces backpressure, which allows the fluid and gas to flow more freely.

- Closing the choke increases backpressure, which stabilizes the well and prevents further influx.

Precise, incremental adjustments are important because even minor changes at the surface can have substantial effects on bottom-hole pressure, particularly when gas is expanding while rising. This step is where operators take great care in balancing flow rate with pressure and maintaining control of the well throughout the kill process.

4. Kill Circulation

During a kill operation, the choke manifold provides for the controlled circulation of kill mud down the drill string and returns the fluid and gas through the annulus. The system is designed to ensure that:

- Bottom-hole pressure is maintained constant during circulation.

- Expansion of gas is done gradually without surges.

- Fluid losses or wellbore fractures are not experienced.

By continuous adjustment of the choke based on surface pressure, operators can effectively bring the well into control with the least possible risk to equipment or people.

5. Dynamic Pressure Management

Besides kill operations, the choke manifold in general is applied for fine-tuning of annular pressure during routine drilling, MPD, and underbalanced drilling. The possibility to regulate flow and pressure in real time makes it a versatile tool; it is indispensable for wells with narrow pressure windows, high gas content, or complex formations.

In essence, the choke manifold system for well control acts as a precision pressure regulator, translating surface manipulations into predictable wellbore pressure responses that enable operators to safely handle influx, circulate kill fluids efficiently, and sustain control in the widest range of drilling conditions.

Training and Well Control Simulators: Enhancing Choke Operation Skills

Operation of a choke manifold system requires much precision, quick decisions, and thorough knowledge of wellbore pressure behavior. Well control situations in the real world are usually hazardous, which calls for the use of well control simulators as a necessary tool to train drilling crews. Simulators provide a controlled environment where operators can safely practice handling complex pressure scenarios without posing any danger to personnel or equipment.

The key benefits of simulator-based training include:

- Realistic well behavior: simulates gas expansion, annular pressure changes, multi-phase flow, and pump rate variations.

- Fine choke manipulation practice: The trainees can incrementally adjust the choke openings in order to observe their direct impact on bottom-hole pressure and fluid returns.

- Scenario-based exercises: these mimic difficult conditions such as rapid influx escalation, valve failures, or multi-choke line switching.

- Team coordination and communication: supports multi-operator training to increase efficiency in responses and decision-making during emergencies.

- Performance evaluation: Monitors reaction time, choke adjustment accuracy, and adherence to well control procedures for feedback and improvement.

By merging realistic simulations with scenario-based challenges, operators develop the technical skill, situational awareness, and teamwork necessary to manage an choke manifold system efficiently. Integrating simulator training into standard well control programs ensures crews are better prepared for real-world kicks, reduces the likelihood of incidents, and promotes safer, more controlled drilling operations.

Final

Essentially, the choke manifold system is considered to be the foundation of wellbore pressure management during drilling, especially in kick conditions and when kill mud circulates. It acts as the operating backbone in surface well control by providing precise regulation of pressures. However, its effectiveness heavily depends on the operator’s skill and understanding of pressure behavior.

Incorporating well control simulators in training ensures that personnel are able to experience complex choke operations in a safe but realistic environment. Combined with sound procedures and a disciplined well control culture, the choke manifold system remains one of the most important tools for maintaining well integrity and preventing blowouts.