How Geothermal Drilling is Used in the Oil and Gas Industry

Geothermal drilling is gaining attention in the oil and gas industry, even though it is primarily considered part of the renewable energy sector. Geothermal energy is seen as a potential ally for traditional oil and gas operations. Due to technological improvements and the oil and gas industry’s incessant quest for new energy sources to enhance operational efficiencies, the industry begins to shift focus to the potential of geothermal drilling to diversify energy sources and improve operational efficiencies. Over time, technological improvements and the quest for cleaner energy have caused the oil and gas industry to shift focus to geothermal drilling.

Geothermal Drilling and Its Relevance to the Oil and Gas Industry

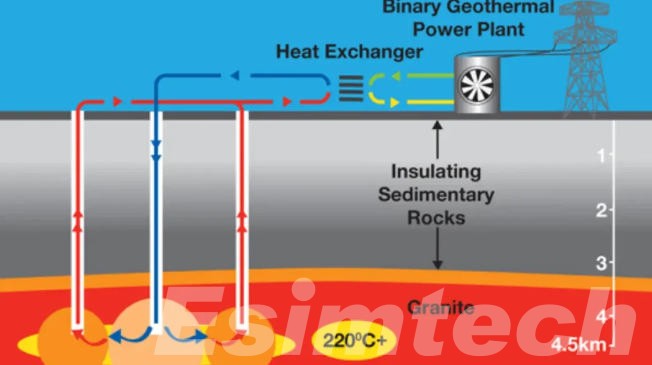

Geothermal drilling refers to the extraction of thermal energy for power generation or for direct use by harnessing the internal heat of the Earth. Although this process is primarily associated with renewable energy, the oil and gas industry already possesses the techniques, equipment and expertise, namely in areas with significant geothermal resources and hydrocarbon reserves.

Considering the advanced drilling resources and capabilities of the oil and gas sector, it is most likely the oil and gas sector will first adopt geothermal drilling techniques. For the oil and gas industry, the potential for profit lies in the ability to expand their energy production with new sustainable resources while for the oil and gas industry, the potential for profit lies in the ability to expand their energy production with new sustainable resources while for the oil and gas industry, the potential for profit lies in the ability to expand their energy production with new sustainable resources.

Key Applications of Geothermal Drilling in the Oil and Gas Industry

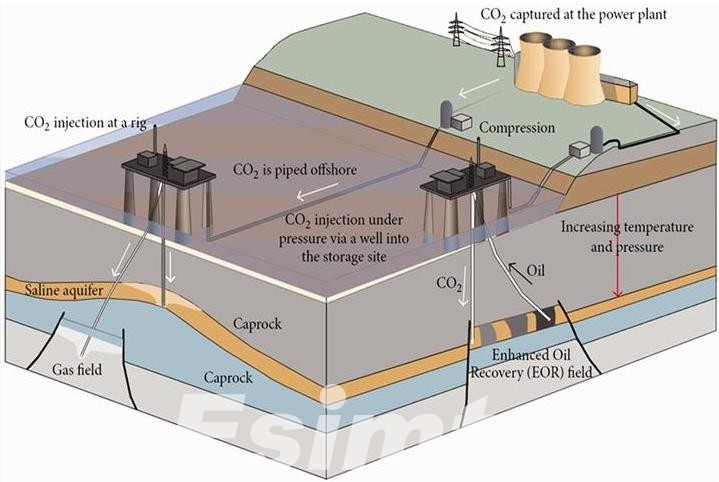

1. Enhanced Oil Recovery (EOR)

One of the most notable techniques involving geothermal drilling in the oil and gas sector is Enhanced Oil Recovery (EOR). Conventional oil recovery practices in older oilfields become inefficient and unproductive in later stages. Heat from geothermal sources is used to inject steam or boiling water into oil reservoirs, lowering oil viscosity, and making it easier to extract and pump. This method, TEOR, improves recovery rates and productive years of the well. Reservoirs benefit from geothermal energy while also optimizing the extraction of the well by removing the last remnants of the oil.

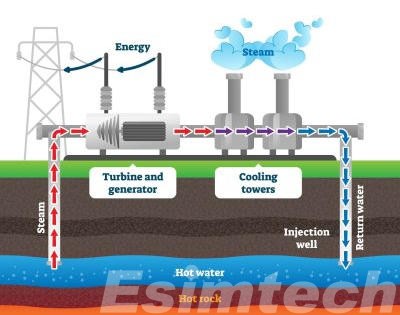

2. Geothermal Power Generation in Oil Fields

Geothermal drilling not only assists oil recovery, but also helps in oil field electricity generation. Where there are abundant geothermal resources, players in the oil and gas arenas can construct geothermal power plants and convert the heat of the Earth into electricity that can be used to fuel oil field operations. This reduces the operational cost by lessening the reliance on external power sources and trimming operational cost. Oil companies shift to geothermal power generation, diminish the carbon footprint, and develop a cost-efficient energy model that self sustains to a degree.

3. Co-Production of Oil, Gas, and Geothermal Energy

Certain oil fields are situated in areas where geothermal and hydrocarbon reserves are present. In such areas, oil and gas companies can pursue co-production by extracting oil, gas, and geothermal energy from the same resource. This is beneficial to operational efficiency and the economic resource value. The oil or gas can be produced simultaneously while the heat obtained from geothermal drilling can be injected into the reservoir for enhanced oil recovery or power generation. Co-production is resource extraction for operational efficiency with the geothermal and fossil fuel energy springs working in synergy.

4. Geothermal Heat for Industrial and Oil Field Processes

Operational costs for oil fields and industrial processes can also be lowered with the use of geothermal energy. Geothermal energy can be used for district heating. For example, hot geothermal well fluids can be used to provide heat to oil refineries and chemical plants as well as to residential buildings. This use of geothermal energy can reduce or eliminate the use of natural gas and other external heating sources, which can result in great savings. In oil field operations, geothermal energy can also be used to provide energy to the more energy-intensive drilling rigs, pumps, and compressors.

5. Improving Sustainability in Oil and Gas Operations

Incorporating geothermal drilling into oil and gas activities improves sustainability. Oil and gas firms look to lessen the negative effects of their activities as the global focus on the reduction of greenhouse gas emissions deepens. Geothermal energy is a safe, renewable energy source and is a substitute for fossil fuels, and it is produced st fossil fuels. Oil firms will be able to lessen their fossil fuel reliance for grid electricity with the integration of geothermal energy into their infrastructures, thus, reducing their unique carbon footprint. Geothermal drilling lowers the negative effects of geothermal extraction such as land costs, freshwater consumption, and degraded oil extraction on the environment by internally lowering the external resource.

6. Technological Innovation and Expertise Transfer

Geothermal drilling can benefit from the oil and gas industry’s experience with deep drilling and wellbore construction. Companies in the oil sector already drill deep into the crust, work with extreme pressures, and handle complex reservoir systems. While drilling geothermal wells, these skills are very important, as wells are drilled to considerable depths and high temperatures are encountered. The oil and gas sector’s development of specialized drilling equipment, heat-resistant materials, and advanced reservoir management techniques has greatly helped the technological progress of geothermal drilling. In addition, oil and gas operations refined horizontal drilling, multi-stage fracturing, and advanced pump systems, which are being repurposed to enhance the efficiency and reduce the costs of geothermal energy extraction.

Technological Innovations Supporting Geothermal Drilling in the Oil and Gas Industry

1. Advanced Drilling Technologies

Geothermal energy drilling is similar to oil and gas drilling, but it requires deeper wells and higher temperatures. The oil and gas industry has had to adjust to the advanced drilling technologies and techniques developed over decades of oil and gas exploration. The innovations in geothermal drilling technology include the previously oil and gas extraction horizontal drilling. This technology allows more precise targeting of geothermal reservoirs leading to more efficient retrieval of ‘thermal’ resources. Companies are able to extract the energy from the geothermal reservoir horizontally, which eliminates the need for them to drill multiple vertical wells.

Managed pressure drilling (MPD) is also another innovative technology in geothermal drilling where the well pressure can be controlled during drilling. This technology is crucial in drilling geothermal wells where the pressure and temperature are very unpredictable. The use of MPD allows drillers to ‘safely’ and ‘efficiently’ drill in ‘highly’ challenging geothermal environments by using real-time data to MPD and ensuring optimal drilling performance regardless of the given conditions.

2. High-temperature Materials and Equipment

When it comes to geothermal drilling, extreme temperatures and pressures at depth constitute the drilling challenge. Designed to withstand drilling conditions, the materials and equipment used must cope with the extreme conditions encountered at depth. In this respect, the oil and gas industry has pioneered the development of heat-resistant materials and specialized equipment that performs successfully within high-temperature geothermal wells.

To illustrate, high-performance drilling fluids, designed to accommodate extreme heat, are utilized to cool the drill bit. Overheating the drill bit is a routine problem during drilling into geothermal reservoirs. To aid drilling, such fluids are meant to retain desirable drilling properties at elevated temperatures. Furthermore, the wellbore is protected from the corrosive effects of hot geothermal fluids with specialized well casings and the use of corrosion-resistant alloys.

The construction of durable drilling components that can function under extreme geothermal conditions has been made possible with the development of superalloy metals. The superalloy metals, that function above 300°C (572°F), improve the reliability and longevity of equipment, thus, less maintenance, and lower costs are incurred during geothermal drilling, and less project downtime is experienced.

3. Enhanced Reservoir Management Techniques

The management of geothermal reservoirs directly affects the efficiency and long-term viability of geothermal energy projects. Some aspects of reservoir management in the oil and gas industry can be innovatively transferred to aid geothermal reservoir management, for example, the real-time monitoring systems for complex reservoirs.

The sustainability of geothermal wells has focused on the improvement of reinjection systems and other downstream processes. For pressure maintenance and resource depletion control, used geothermal fluids are reinjected after energy production. More advanced systems of reinjection also expand the efficient operational time of the geothermal energy systems.

4. Integrated Digital Technologies for Data Analysis

The oil and gas industry has been a pioneer in implementing new digital technologies for operations optimization. In geothermal drilling, new digital solutions such as the Internet of Things (IoT) and Artificial Intelligence (AI) technologies are vital for improving operational efficiency.

IoT sensors gather and analyze real-time data down to the geothermal wells, gaining insight on key wellbore conditions, determining wellbore pressures, and detecting liquid heat. The data for the monitoring well is electronically sent to a central command console where operational adjustments can be made in real-time. IoT devices perform automated declines predictive maintenance where all components of the system are compared against known operating limits in the equipment to predict potential equipment failures, thereby reducing downtime and maintenance costs.

Geothermal operations produce massive amounts of AI and ML data. Geothermal drilling AI systems predict and optimize future reservoir behaviors, recommend new drilling well locations, and drilling parameters in real-time, all by analyzing historical data and drilling predictive models. Advanced drilling techniques optimize and improve the operational drilling efficiencies.

In thermal drilling, the use of big data for modeling is also crucial. Companies are able to capture operational data to assess and enhance drilling efficiency. The performance improvement using saved operational data decreases operational costs and lessens the environmental footprint.

5. Geothermal Drilling Rigs and Equipment Innovations

Greater efficiency, versatility, and drilling capacity in difficult geothermal conditions have led to many more technological improvements in geothermal drilling rigs. For example, geothermal operations are seeing more use of modular drilling rigs, allowing more flexible and easier to transport use in remote and difficult to geo-access locations for off-grid geothermal drilling projects.

Also, we now have more pinpoint control over the drilling and more modular and flexible top-drive drilling systems. More top-drive systems are now in use, particularly in geothermal drilling, where more control is needed to prevent operational problems, and to avoid damage to the wellbore. The use of top-drive systems removes more manual drilling work and improves the safety and efficiency of the drilling process.

6. Advancements in Drilling Automation

Technological improvements like automation of drilling functions are also having positive impacts on the geothermal drilling processes within the oil and gas sector. The use of automated drilling frameworks is expanding to minimize human contact, enhance safety, and improve the efficacy of the drilling process. Automation frameworks that rely on sensors and AI to perform real-time data analytics can, for example, automatically control the drilling parameters of bit rotational speed, mud flow, and weight on the bit.

Automated drilling systems also facilitates remote diagnostics of the drilling units, which allows the personnel to troubleshoot and assess well control remotely and synoptically. This remote control of well boring functions minimizes the need for personnel to be on-site, thereby enhancing safety and reducing risks associated with human activities.

7. Simulation Technologies

This chart shows the diverse applications of simulations in geothermal drilling, highlighting how it aids in optimizing performance, minimizing risks and improving operational efficiency in the oil and gas industry.

| Simulation Type | Purpose | Key Benefits | Example in Geothermal Drilling |

| Reservoir Simulation | Model the behavior of geothermal reservoirs under extraction scenarios | – Predict reservoir performance over time – Optimize well placement – Enhance resource management | Simulate thermal, fluid, and pressure behavior in geothermal reservoirs to maximize energy production |

| Wellbore and Drilling Simulation | Simulate drilling conditions and wellbore integrity | – Identify potential drilling issues – Optimize drilling parameters – Ensure safe operations | Model wellbore stability and determine the best drilling methods to avoid stuck pipe incidents |

| Heat Flow Simulation | Model heat transfer from geothermal reservoirs to the surface | – Ensure efficient heat extraction – Predict temperature profiles – Optimize energy production | Simulate heat loss and temperature changes along the wellbore to improve system efficiency |

| Mechanical Drilling Simulation | Simulate mechanical aspects of the drilling process | – Optimize drill bit speed and weight – Prevent equipment failure – Reduce downtime | Determine optimal drilling parameters such as bit speed and mud circulation rates |

| Thermal Management Simulation | Assess heat management and thermal stability during geothermal extraction | – Ensure long-term system stability – Maximize energy efficiency – Avoid heat fluctuations | Simulate the interaction between geothermal fluids and surrounding rock for thermal stability |

| Enhanced Geothermal Systems (EGS) Simulation | Model fluid dynamics in fractured rock systems | – Improve heat transfer efficiency – Optimize injection/extraction rates – Enhance EGS performance | Simulate fluid flow in fractured rocks and assess heat exchange to enhance EGS productivity |

Economic and Environmental Benefits of Geothermal Drilling for Oil and Gas Companies

Integrating geothermal energy into conventional oil and gas extraction activities presents companies with various gains which are both economically and environmentally beneficial.

1. Cost Reduction through Geothermal Energy Use

Geothermal drilling can provide significant savings to the oil and gas sector. Companies in this sector require a considerable amount of external energy to operate, especially in the areas of pumping, drilling, and refining. Companies can offset some of their costs by employing geothermal energy for on-site electricity generation, as they will need less power from the grid and will rely less on fossil fuels for energy. Cost savings on energy can markedly reduce the operational costs of oil and gas drilling in remote areas, since energy is also expensive and difficult to access in those locations.

2. Diversification of Energy Portfolio

The move towards cleaner sources of energy makes diversification a growing priority for oil and gas operators. Geothermal drilling will provide the oil and gas sector with the necessary diversification. Companies will use less fossil fuels as they gain geothermal resources in addition to their drilling and gasextraction activities, as oil and gas extraction will still remain the main part of their business.

Such diversification allows companies to avoid some of the hazards linked to changes in oil prices and the pressures of regulations regarding carbon emissions. In places that have geothermal resources, geothermal energy integration allows companies access to market-volatile resources which helps companies reduce exposure to unpredictability in revenue during volatile periods. This improves the predictability of revenue.

3. Social and Community Benefits

Social and community benefits are possible with geothermal drilling in addition to the economic and environmental benefits. The use of local geothermal energy resources helps to lessen the energy production environmental consequences and benefits nearby communities. With less pollution and more economic opportunities, stakeholders have more to gain from the alleviation of negative consequences from geothermal energy development. This facilitates improved community relations.

Geothermal energy, for instance, is used for district heating and can provide electricity to remote communities that have little to no power. This strengthens community development and promotes oil and gas companies’ new role of regional sustainability.

4. Regulatory and Policy Benefits

Regulatory renewables and environmental governance are a major focus for numerous countries. For these countries, renewables, especially geothermal energy, are accompanied by tax breaks, grants, and other subsidies. Geothermal drilling projects for oil and gas companies can utilize these subsidies and incentives which lower the overall cost and help financial undergone assessment for geothermal drilling projects to become positive.

Lower environmental impact further strengthens the business case and appeal for geothermal drilling in oil and gas companies under stringent environmental governance framework. Geothermal drilling promotes oil and gas companies to become regulators for greenhouse gas and carbon regulated pollutant discharges in their operations promoting environmental sustainability.

5. Long-Term Energy Security and Resilience

Geothermal drilling enhances energy security not only for the oil and gas companies, but the nations too, as it provides a reliable and renewable energy source. Geothermal energy adopts a bottom-up approach and promotes local and stable supply. Companies of the oil and gas sector which operate in geothermal rich zones will build a strong and resilient energy infrastructure that can withstand geopolitical supply shocks and climate driven price shocks associated with fossil energy.

The stability offered by geothermal energy is appealing for oil and gas firms seeking to construct more robust operations. Oil and gas firms blending geothermal energy and drilling into their energy mix will have access to a more secure and stable energy supply regardless of unpredictable global shifts.

Challenges and Future Outlook of Geothermal Drilling in the Oil and Gas Industry

This chart provides the key challenges currently faced by the geothermal drilling sector in the oil and gas industry, along with a forward-looking perspective on how these challenges might be addressed in the future.

| Challenges | Description | Impact on Operations | Future Outlook |

| High Initial Capital Costs | Geothermal drilling requires significant upfront investment in drilling equipment, infrastructure, and technology. | High financial barriers to entry, particularly for companies without access to large capital. | Investment in geothermal technology is expected to decrease as efficiencies improve and more companies adopt it. |

| Geological and Reservoir Uncertainty | Geothermal reservoirs are often difficult to assess, with complex and variable conditions. | Uncertainty in reservoir performance leads to higher risks and potentially lower yields. | Advances in simulation technologies and better reservoir modeling techniques will improve predictability and reduce uncertainty. |

| Extreme Temperatures and Pressures | Geothermal drilling takes place in extreme conditions, where temperatures and pressures can exceed normal operating limits. | Increased wear and tear on equipment, higher operational risks, and greater maintenance costs. | Development of new high-temperature materials and drilling technologies will improve equipment durability and efficiency. |

| Limited Geothermal Resource Accessibility | Geothermal resources are geographically limited and may not always align with existing oil and gas fields. | Increased difficulty in finding viable geothermal resources in certain regions. | Exploration of new geothermal resources, such as Enhanced Geothermal Systems (EGS), will open new areas for development. |

| Environmental Impact Concerns | While geothermal energy is low-carbon, improper management can lead to surface degradation, water usage concerns, and potential seismic risks. | Public opposition and regulatory scrutiny may slow the adoption of geothermal projects. | Continued research into sustainable practices and regulatory incentives will help reduce environmental concerns. |

| Regulatory and Policy Barriers | Lack of standardized regulations and clear policies for geothermal drilling in the oil and gas sector. | Uncertainty around government support, funding, and policy changes could delay projects. | Governments are likely to increase support through tax incentives, grants, and clear regulatory frameworks as demand for renewable energy rises. |

| Skill Gaps and Knowledge Transfer | Geothermal drilling requires specialized knowledge and expertise that differs from traditional oil and gas drilling. | Shortage of trained personnel, leading to higher training costs and delays in project implementation. | Growing demand for geothermal energy will drive training programs and educational initiatives to close the skill gap. |

| Competition from Other Renewable Sources | Geothermal energy competes with other renewable sources like wind and solar, which may have lower installation costs. | Geothermal may face challenges in being considered the most cost-effective renewable energy source. | Increased integration of geothermal with other renewables (e.g., hybrid energy systems) could provide competitive advantages. |

Summary

Incorporating geothermal drilling offers a chance for oil and gas operations to transform and aid in the transition to more sustainable energy practices. Oil and gas companies can streamline geothermal resource exploitation for power generation and enhanced oil recovery by utilizing their mastery of drilling practices and reservoir management. The incorporation of geothermal drilling into oil and gas operations will provide a number of benefits, including economic, environmental and competitive advantages in a business climate increasingly favoring green energy. Geothermal drilling will be a cornerstone of oil and gas industry in the future as technology improves and the market for clean energy expands.