How to Use Simulators to Optimize Oil Recovery Plan Design

Optimizing oil recovery in the modern oil and gas industry is as much a matter of technology and engineering models as it is a matter of human beings operating and maintaining these systems. Without a well-trained workforce, even the most sophisticated plans are at an execution disadvantage. Training simulators bridge this most critical gap.

By the recreation of internal structure, working principle, and functions of oil recovery simulators provide workers—ranging from novice machine operators to seasoned technologists—hands-on exposure in a safe environment. This hands-on knowledge automatically enables the conceptualization and execution of more effective, reliable, and safer oil recovery schemes.

The Role of Training Simulators in Oil Recovery

Oil recovery means engaging a long list of equipment and sophisticated workflows from wellheads and downhole pumps to surface separation systems. For operators, technicians, and students, understanding how all of them function individually and as part of an integrated system is the difference between efficiency and waste. Classroom learning or minimal on-site exposure simply cannot offer the level of knowledge and hands-on experience.

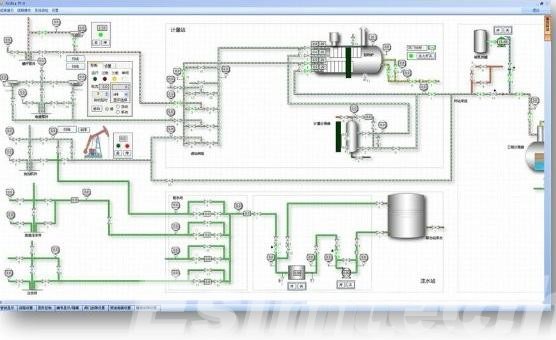

This is where training simulators for oil recovery are useful. By replicating equipment layouts, dynamic processes, and operations in a virtual or real environment, simulators allow students to “see inside” machines, interact with process streams, and practice standard operating procedures. Most importantly, they offer a safe and controlled environment within which common faults and accident scenarios can be simulated so that trainees can gain confidence and troubleshoot without risking real consequences.

Being a firm that produces and designs such systems, we build simulators to address different levels of training—from new staff that needs to learn equipment basics, to experienced technologists that need to learn complex workflows and emergency handling. Simulators end up making the workforce more robust, and this is vital in executing and optimizing oil recovery strategies.

How Training Supports Plan Design Optimization

Acquiring and designing an effective oil recovery plan is not an easy endeavour. It requires not only the implementation of theoretical designs and engineering calculations but also an in-depth understanding of how to use real designs and equipment alongside the theoretical calculations. This is where the use of training simulators comes in. They allow engineers and operators to address the pieces of theory and practical aspects that go into the execution and design of plans in the most optimal way.

Theory Versus Practice

It is not uncommon for recovery plans to be sourced from technical models and reservoir data. However, the execution of these plans almost always fails. This is where simulators come in. They help learners interface with either physical or virtual pumps, flow systems, or separators and system flow. Attaining and applying theoretical knowledge, in addition to real-world knowledge, is very critical because the feedback that is provided is vital to assist engineers in crafting more physical and practicable recovery plans and strategies that can be employed.

Enhancing Team Competence

An oil recovery process requires teamwork. It is no surprise that simulators work for the training of operators, senior technologists, and even mid-level technicians. Teams with a standard training module tend to execute plans in a more accurate and efficient manner, eliminating any unnecessary delays associated with the project, as well as optimising the project outcomes.

Minimizing Human Factors in Plan Execution

Plans can be, and have been, derailed, no matter how well they were designed, due to valve operation errors, sequences of the pumps, or simple mistakes with the monitoring systems.

Simulators give users the opportunity to carry out monotonous tasks while correcting mistakes in a controlled setting. This minimises errors in actual missions and maximises adherence to the plans.

Considerations for enhancing safety in design.

Dealing with incidents is an important part of recovery planning. The use of training simulators makes it possible to practise emergency procedures such as any troubling equipment failing and the pressure going awry. The lessons from these sessions suggest to design corset and recovery planners to include more generous safety margins.

Increased knowledge and skill on the subject coupled with heightened safety awareness among employees makes training simulators an integral part of the design and effective use of the plans for oil recovery.

Case Applications of Oil Recovery Simulators

Simulators of oil recovery processes are impressive tools that aid learning at both vocational levels as well as in specialised oilfield training programmes. Regardless of the level of training, both individuals and firms appreciate practical implementations of plans and new concepts.

- For New Entrants

Helping learners at the novice level involves introducing them to the nuts and bolts of well pumps, separators, valves and head works, and other practical elements. This level of understanding enhances practical application without physical interaction with the expensive and dangerous field instruments.

- For Intermediate Technicians

Prospective recovery practitioners are provided in training with practical skills training in the coordination of system components and integration of multi-factorial systems, such as flow rate control, pressure regulation, and system production. Such routine exercises enable application of recovery plans with precision and self-assurance.

- For Technology and Engineering Specialists

At the advanced level, users are exposed to multi-dimensional interactions with systems that can stick, malfunction, or require other situational responses to emergencies and faults. In oil recovery, the simulated environment allows the user to practice the complex multi-dimensional systems of accountability, enhancing their rational step formulation to many changing system parameters.

- For Training Institutions and Oilfield Operations

Educational institutions and oilfield companies utilise simulators for the purpose of uniform training so that every individual including students and even seasoned employees have the same working knowledge of the processes and protocol including safety measures. This also enhances the execution and improves the analysis in the planning stage at the same time.

When oil recovery simulators take into consideration the distinct demands of various user populations, they become training devices and simultaneously, a comprehensive link between the development of the oil recovery workforce and efficient oil recovery planning.

Benefits of Using Training Simulators in Oil Recovery Planning

Incorporating oil recovery simulators into training practices yields significant rewards for both employee training and productivity.

- One of the benefits associated with training using simulators with the recovery drilling method is the decreased time required to master the skills. Trainees master the complex formation of machines, the working configuration, and the operative steps in a much shorter time with little on-the-job training compared to the older methodologies, thus attaining a higher proficiency faster.

- Another important benefit from the use of simulators is the reduction in cost. Simulators eliminate the need for physical equipment for training and, as a result, a reduction in ‘downtime’, training/maintenance costs and related disturbances is achieved. Not only does the organisation benefit from the simulators, as the scheduled training sessions can be offered for multiple users simultaneously, resource use is optimally managed.

- When compared to ‘real-life’ scenarios, using simulators improves operational conduct as participants master the procedures of equipment malfunctions, emergency power shunt, and absence of normal operational conditions. The likelihood of real-life accidents is decreased and personnel proficiency is thus enhanced.

- In the oil recovery performance plans, simulators have a direct and relevant value as they enhance the skills of recovery operators and rotary drilling technicians. Competent and experienced oil recovery operators and rotary drilling technicians deliver plans on accurate working streams with reasonable backfeeds, fulfilling the closed-loop of information circulation required. This stimulates continuous improvement. The feedback directs operational workflows, procedures, and safety enhancements to be refined from insights gained from the simulation training.

All in all, simulators do not only improve employee skills and confidence but also improve safety and reduce costs, make oil recovery plans easier and more effective, and improve overall operational efficiency.

Best Practices for Integrating Simulators into Training & Design

To optimize oil recovery simulator effectiveness, organizations need to install systematic best practices that directly relate to operational planning and manpower development.

1. Customize Training by Function

Develop the simulator modules to match the unique needs of different roles. New operators are trained in equipment fundamentals, mid-grade technicians in workflow coordination, and master engineers in handling advanced scenarios, including emergency response and process optimization. Training based on roles enables every team member to achieve the proficiency that matches their role.

2. Align training with recovery plan design

Incorporate learner feedback and simulation outputs into the planning cycle. Planners are made aware of how equipment is used by operators in order to develop more realistic, practicable, and safe plans for oil recovery. This maintains a direct feedback loop between optimization of the plan and learning.

3. Update Simulators Periodically

As operating methods, equipment, and technology evolve, simulation material has to be revised regularly to keep pace with new industry standards and developments. Through this approach, trainees are prepared for the operational challenges of today and tomorrow.

4. Build Continuous Feedback Loops

Make certain that trainees and instructors provide feedback on operational bottlenecks, process problems, and common errors. This type of information can be used to make changes to training as well as to plan design, fostering a culture of continuous improvement.

5. Link Training with Certification

Using simulators in formal certification programs raises competency levels, credibility, and regulatory compliance for operations and safety.

Using these best practices, oil recovery simulators are thus a strategic resource that builds workforce capability, safety, and the ability to generate optimized, actionable recovery plans.

Optimizing oil recovery plan design is not only a technical challenge but also a human one. By equipping workers, technicians, and engineers with the skills to understand equipment, master workflows, and handle emergencies, training simulators bring theory to life.

For operators, simulators accelerate learning and reduce errors. For planners they provide critical feedback that enhances the practicality, safety, and efficiency of recovery strategies.

Any interests? Contact us for more detailed information!