What Is an Oil Drilling Simulator and Why Every Training Center Needs One

Traditional methods, training personnel for operations in the oil and gas sector are always a challenging task. Traditional methods came along with costly gear and limited hands-on training opportunities. Actual rigs must contend with costly safety incidents and environmental concerns, as well as expensive downtime.

An oil drilling simulator is exactly what is needed. They allow immersive training on a drilling rig without real-world risks. For the drilling rig and well control simulators, as well as for emergency response training, these advanced systems are transforming how training centers prepare the next generation of drilling specialists.

This article will discuss what an oil drilling simulator is, how an oil drilling simulator works, and its benefits. More importantly, we will discuss its importance for training centers and why they need to integrate simulators into their programs.

What Is an Oil Drilling Simulator?

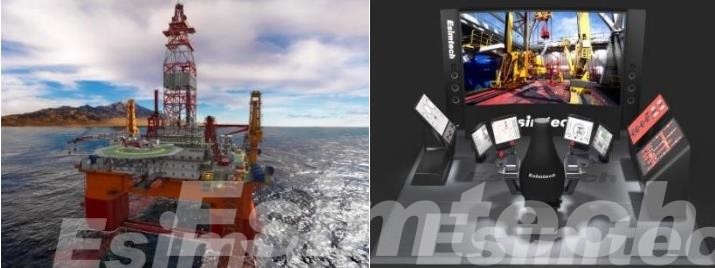

Oil drilling simulators are sophisticated training tools created to imitate drilling rig operations with their multifaceted activities in a controlled environment, free from any potential hazards.

- Unlike the traditional training methods which require hands-on experience on costly drilling rigs, where errors can lead to significant consequences, drilling simulators offer an environment where trainees can practice and refine their skills without any risks.

- Users can practice all aspects of drilling operations, from basic rig controls and well control to more complex operations through the combination of advanced software modeling and realistic hardware interfaces. To enhance immersion, some simulators go a step further and incorporate virtual reality or 3D environments.

- Many training centers, oil and gas corporations, and even some educational institutions take advantage of these simulators for training purposes. They prepare operators to deal with a variety of challenges such as equipment failure, emergencies, and even more complex strategic operational decisions while ensuring their safety.

- Oil drilling simulators enable trainees to gain practical experience in a controlled setting which complements their theoretical knowledge, significantly improving their competence and confidence. This ease of access to modern training tools has completely transformed drilling training programs across the globe.

How Does an Oil Drilling Simulator Work?

An oil drilling simulator functions by mimicking the physical, operational, and decision-making processes of drilling in a virtual setting. At the heart of the simulator is a blend of high-fidelity oil drilling simulation software and sophisticated hardware systems, which permit the trainees to engage with the hardware interfaces as they would on a proper drilling rig.

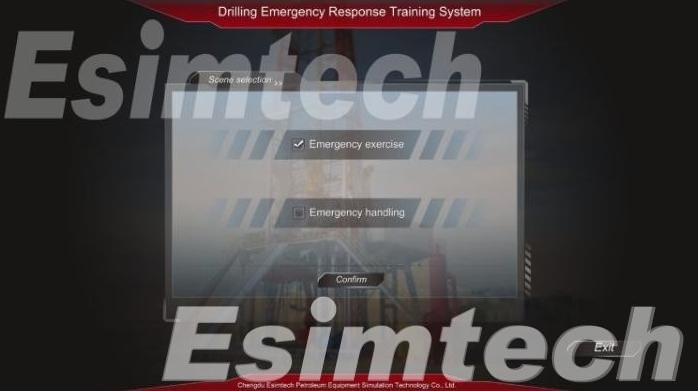

- Drilling simulators are equipped with software engines that simulate critical drilling processes like drill bit functions, the flow of drilling fluids, pressurized systems, and the stability of the drilled hole. It also responds to trainee actions and simulates emergencies that are not predefined, including routine operations. For instance, a trainee not managing mud weight appropriately or not recognizing a pressure anomaly will result in the simulator simulating a kick or blowout.

- In terms of hardware, simulators are equipped with control and touch screens, as well as joysticks and even cabin replicas of the rig drilled at full scale. The touch screens and controls integrate with real drilling equipment, which allows trainees to gain practical experience and develop their skills and confidence in the area through practice.

Drilling Emergency Exercise Simulation Training System touch screen

- Some advanced simulators may integrate virtual or augmented reality (VR or AR) technologies to place the trainees in a drilled rig 3D environment. This not only allows the trainees to gain a comprehensive appreciation of the rig’s layout, but also enhances their teamwork and spatial awareness, as many operators can participate in combined simulated drilling exercises for offshore or onshore drilling.

- Instructors can customize training scenarios to capture different drilling environments, operational difficulties, and safety protocols. This flexibility enables scalable and specific training programs to be developed, equipping operators to manage intricate drilling operations safely and efficiently.

- Realistic oil drilling simulators combine classroom theory with hands-on practice by incorporating advanced software modeling, interactivity, and scenario-based exercises. This formulation makes trainees ready for the rig floor.

Key Benefits of Oil Drilling Simulators for Training Centers

The incorporation of an oil drilling simulator in a training program has obvious benefits for both the students and the instructors.

- In contrast to classroom instruction, simulators offer interactive and hands-on learning that closely mimics actual drilling procedures, allowing trainees to acquire hands-on skills without being subjected to risk.

- The most significant and primary benefit is safety. Simulators allow students to train on well control issues, equipment failure, and unexpected drilling issues in a simulated environment. This builds confidence and preparedness for real emergencies without risking personnel or equipment.

- Cost savings is another important advantage. Live rig training is expensive and at times not practical. Simulators reduce the need for costly rig time while still offering realistic operating experiences. They also enable practice repeats, not always possible in the field.

- Training centers also benefit from flexibility and scalability. Instructors can design custom training modules for different levels of expertise, from entry-level operators to seasoned professionals seeking certification. In addition, most industry standards and accrediting bodies now suggest or require simulator-based training, so it is also a handy tool for compliance.

- With increased safety, cost efficiencies, and better learning outcomes, drilling simulators give training facilities a competitive edge and better equip students for the realities of oilfield operations today.

Why Every Training Center Needs an Oil Drilling Simulator

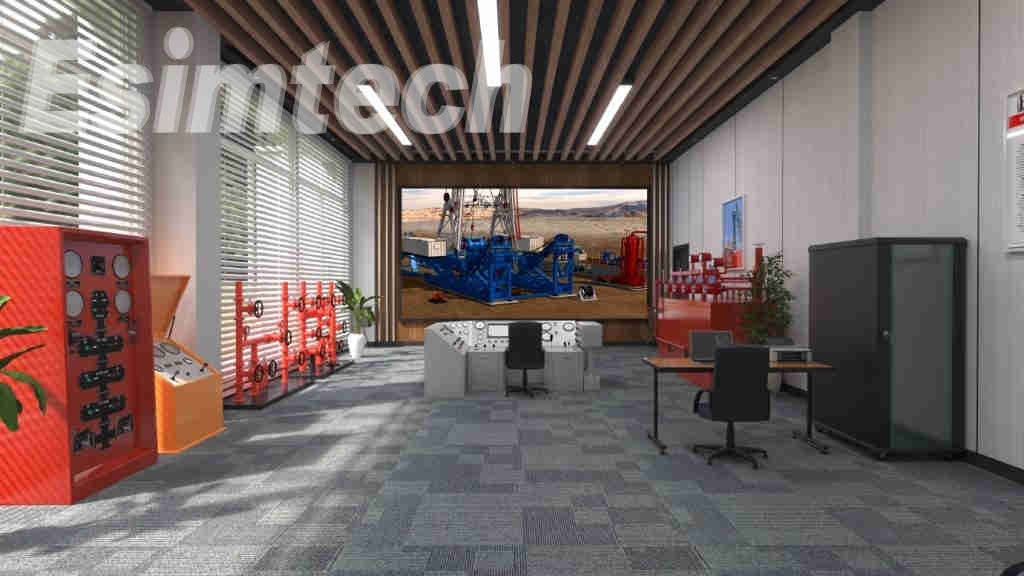

In the current oil and gas drilling market, the need for appropriately trained drilling personnel has peaked. Instructors who depend entirely on lectures or limited field work often find it extremely difficult to prepare their students for the multifaceted nature of real drilling operations. An oil drilling simulator significantly sharpens the edge, as it provides a safe and realistic training environment at a low cost.

Training centers can improve their marketing, as well as attract students and corporate sponsors through better programs by adding simulators. Employers value more graduates with practical and simulated work experience, as it lessens the time and danger needed to adapt to real work. Simulators also help meet global training criteria, increasing the program’s credibility.

An oil drilling simulator is more than a tool, it is a strategic investment. The simulator sharpens learning outcomes, enhances institutional reputation, and helps training centers keep pace with advancements in the energy sector.

Choosing the Right Oil Drilling Simulator

Because there are several technologies available, the selection of an oil drilling simulator is a significant decision for organizations and training institutions. The ideal system should not only simulate the technical aspects of the drilling operation, but also be appropriate for the specific training goals of the institution.

- As a first-hand experience, the institution should first prioritize the requirements of realism and accuracy. The simulator should effectively capture the physics of drilling, well control, and the behavior of equipment, as well as reliable modeling of the equipment. Valuable the simulator is, the more the training experience becomes.

- Equally effective are other attributes like Flexibility and Scalability. The institution should be able to find a balance between entry-level and advanced professional training. The scenario training, where several students are trained, and where students are trained on different drilling environments, both bring a large scale of value.

- Technical support and equipment upgrades should also be noted. The oil and gas industry is, and uses technology to keep reforming standards and practices. A manufacturer that supplies ongoing maintenance, instructor training, updates, and continuous document revisions retains the effectiveness of a designed investment.

- Finally, organizations should evaluate adherence to industry standards. Compliance with accreditation bodies enhances the appeal of training programs to the students and corporate clients.

At Esimtech, we are focused on creating oil drilling simulators with realistic physics and adjustable training components that meet industry norms. Our simulators are used by universities, training centers, and energy companies across the globe who seek safe, effective, and modern drilling training.

If you are in any need of oil drilling simulation training system, please feel free to contact us!