What is Multistage Fracturing? A Simple Explanation

Multistage fracturing is a revolutionary technique in the oil and gas industry that enhances well productivity by creating multiple fractures along a horizontal wellbore. This method has transformed unconventional resource extraction, making it possible to access previously unreachable reserves.

Basics of Multistage Fracturing

Multistage fracturing is an advanced well stimulation technique used to maximize oil and gas production from horizontal wells. As opposed to standard hydraulic fracturing techniques which treat an entire well as one zone, multistage fracture therapy divides up its wellbore into segments which are individually fractured; this approach dramatically enhances reservoir drainage rates as well as recovery rates.

Traditional hydraulic fracturing focuses on vertical wells with one large fracture; multistage fracturing on horizontal wells allows operators to create multiple smaller, controlled fractures along their length ensuring more of the rock formation is reached for hydrocarbon flow.

Key Components of the Process

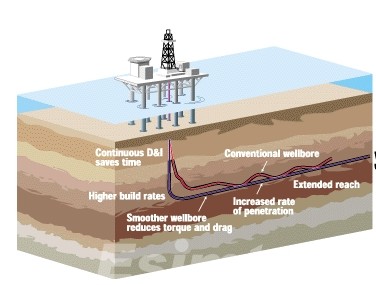

- Horizontal Drilling: Wells are typically drilled laterally through tight rock formations to uncover more reservoir rock.

- Stage Isolation: Mechanical plugs or sliding sleeves divide a well into separate stages for precise stimulation of each stage, providing accurate stimulation results.

- Targeted Fracturing: Each stage is perforated and then filled with high-pressure liquid (water, sand, or chemicals) in order to create fractures in its foundation.

- Proppant Placement: Sand or ceramic proppants help open fractures so oil and gas can flow more freely through them, increasing flow efficiency.

By breaking up their well into multiple stages, operators can ensure optimal fracture placement, maximize production rates, and cut waste, making multistage fracturing one of the cornerstones of modern unconventional resource extraction.

How Multistage Hydraulic Fracturing Works

Multistage hydraulic fracturing is a carefully engineered process that maximizes oil and gas recovery from horizontal wells. Here’s a step-by-step breakdown of how it works:

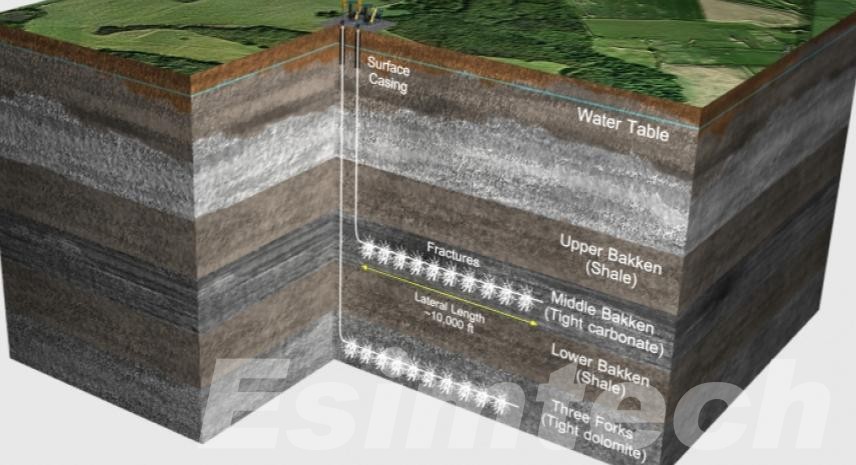

The process starts by drilling a vertical well that will eventually be slowly guided horizontally through target rock formations such as shale or tight sandstone, providing access to more of the reservoir’s resources. This step may last thousands of feet.

2. Casing and Perforation

Once drilling has concluded, steel casing must be installed to stabilize the well, and the engineer then uses perforating guns to punch small holes at predetermined intervals along the casing for perforating purposes; each mark marking the start of a new fracture stage fracturing session.

3. Stage Isolation with Plugs or Sleeves

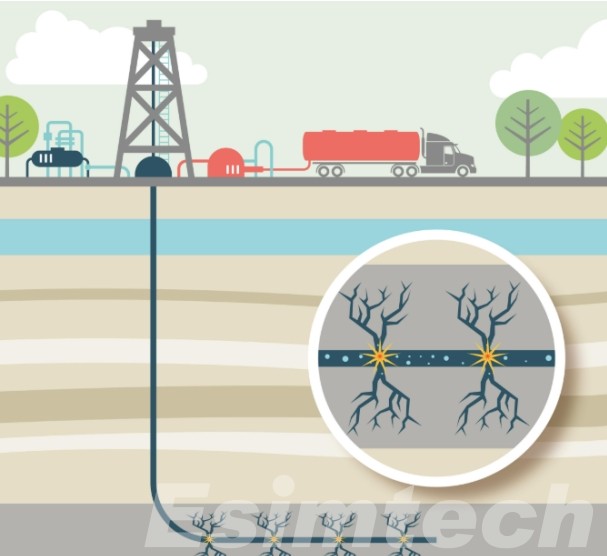

To fracture one section at a time, temporary plugs or sliding sleeves are deployed at each stage to isolate it and ensure high-pressure fluid is directed solely toward its target zone without interference between stages.

4. High-Pressure Fluid Injection

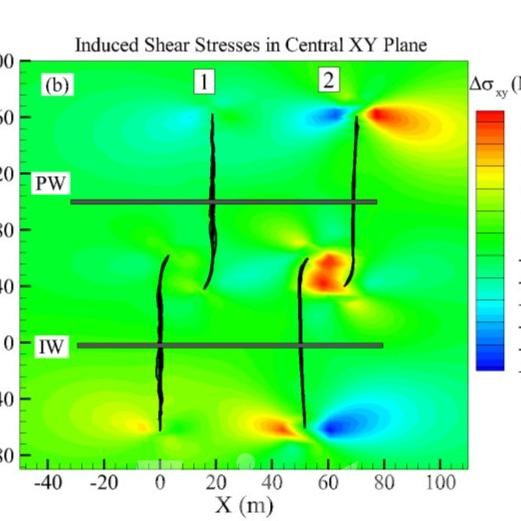

To create tiny cracks that allow trapped hydrocarbons to escape from underground reservoirs, an injection of specially formulated fracking fluid, composed of water, proppant (proppants), and chemicals, into an oil or gas well at extremely high pressure is administered with special pumps that pressurize it with fluid under extreme pressure. Fracking creates fractured rock surfaces to release trapped hydrocarbons more freely for production and exploration purposes.

5. Proppant Placement

As fractures form, sand or ceramic proppants must be added to keep them open; without this measure in place, fractures would close upon pressure release, blocking oil and gas flow.

6. Repeating the Process for Each Stage

After completing one stage, the next isolated section is perforated and fractured. Modern techniques, like plug-and-perf or ball-activated sleeves, allow operators to efficiently move from one stage to the next without pulling equipment out of the well.

7. Flowback and Production

Once all stages are fractured, the isolation plugs are drilled out (if used), and the well is cleaned. Hydrocarbons begin flowing to the surface, where they are collected for processing.

This method ensures maximum reservoir contact, significantly boosting production compared to traditional single-stage fracturing. Advances in monitoring technologies, such as fiber-optic sensors, further optimize the process by providing real-time data on fracture growth and fluid distribution.

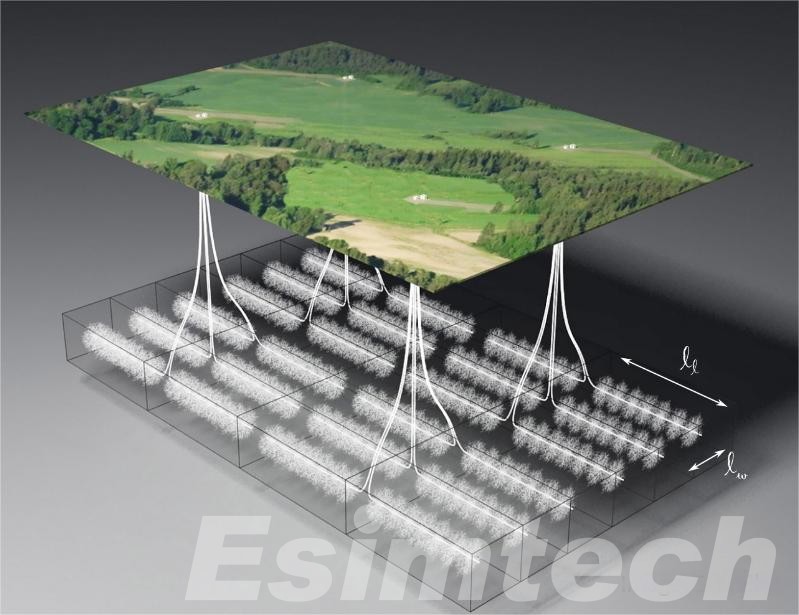

By breaking the well into multiple stages, operators can extract more resources with fewer wells, making multistage fracturing a cornerstone of modern shale development.

Advantages of Multistage Fracturing

Multistage fracturing has revolutionized oil and gas extraction by significantly improving well productivity and efficiency. Here are the four most important advantages of this advanced technique:

1. Dramatically Increases Hydrocarbon Production

Unlike traditional single-stage fracturing, multistage fracturing stimulates multiple sections of a horizontal well, creating a network of fractures that expose more of the reservoir to the wellbore. This leads to a much higher flow of oil and gas. In shale formations, where natural permeability is extremely low, this method can boost production by 300% or more compared to conventional vertical wells. By maximizing reservoir contact, operators extract more resources from a single well, improving overall field economics.

2. Improving Reservoir Drainage & Recovery Rates

Multistage fracturing ensures even the tightest rock formations can be effectively reached, and each stage targets different parts of a well to allow precise stimulation of its reservoir. This prevents unintended interference between wells called “frac hits”, and ensures more uniform hydrocarbon drainage from each well, increasing recovery rates as more oil or gas from the reservoir surface, decreasing wastefulness, and increasing long-term profitability.

3. Reduce Operational Costs & Drilling Footprint

Drilling multiple vertical wells to achieve similar production as one multistage-fractured horizontal well is considerably more costly and land-intensive. At the same time, multistage fracturing enables operators to maximize output using fewer wells, thus decreasing drilling rig, surface equipment, labor cost, as well as environmental impact (less land disturbed and reduced carbon footprint of operations) significantly.

- Improved Well Economics & ROI

Because multistage fracturing extracts more hydrocarbons per well than traditional methods do, its return on investment (ROI) is significantly greater, leading to faster payback periods even for marginal or difficult reservoirs and making economic viability an attractive proposition. Furthermore, innovations like plug-and-perf technology have made multistage fracturing even faster and more reliable, further cutting costs and improving efficiency.

Multistage fracturing is a key driver behind the success of modern shale oil and gas production. By boosting production, enhancing recovery, cutting costs, and improving ROI, this technique has made previously uneconomical reservoirs profitable while supporting more sustainable resource extraction. As technology continues to evolve, multistage fracturing will remain essential in meeting global energy demands.

Where Multistage Fracturing is Used

Multistage fracturing is a key technology in unlocking hydrocarbons from challenging reservoirs. It is primarily used in the following four major applications:

Tight Sandstone and Carbonate Reservoirs

Unlike conventional reservoirs where oil and gas flow naturally, tight sandstone and carbonate formations have very small pore spaces, restricting fluid movement. Examples include the Bakken Formation and the Haynesville Shale.

Multistage fracturing is used to enhance permeability by creating artificial fractures that connect these tiny pores to the wellbore. Engineers design each stage to target the most productive zones, ensuring maximum recovery. This method has extended the life of many mature fields and enabled production from reservoirs once considered too difficult to develop.

Shale Gas and Oil Formations

Shale plays like the Marcellus Shale, Eagle Ford, and Permian Basin are some of the most sought-after targets for multistage fracturing. These particular rocks are extremely low in permeability, which means that the oil and gas cannot freely flow to the wellbore without stimulation.

Multistage fracturing breaks up the tight shale rock along the length of a horizontal well, creating a complex network of fractures that release the hydrocarbons trapped inside. This groundbreaking method has revolutionized U.S. energy production, turning previously uneconomic shale plays into major contributors to the world’s oil and gas supply. Absent the development of multistage fracturing, commercial production of shale gas and tight oil would continue to be an impossible task.

Coalbed Methane Extraction

Coalbed methane (CBM) is gas trapped in coal seams. While natural production of gas from some CBM wells occurs, the majority are stimulated due to low permeability.

Multistage fracturing helps by opening up coal fractures through which methane can desorb and migrate to the surface. It is particularly useful in the Powder River Basin (U.S.) and the Bowen Basin (Australia), where coal seams are deep and tightly bedded. With staged fracturing, operators can improve gas recovery rates without producing too much water, a common issue of CBM operations.

Enhanced Geothermal Systems (EGS)

Beyond oil and gas, multistage fracturing is also being adapted for geothermal energy. Enhanced Geothermal Systems (EGS) involve creating fractures in hot, dry rock to circulate water and extract heat for power generation.

While still an emerging application, EGS could benefit greatly from multistage fracturing techniques. By isolating and stimulating different sections of a well, engineers can improve heat exchange efficiency, making geothermal energy more viable in areas without natural hydrothermal resources.

This expanded section provides deeper insights into each key application of multistage fracturing while maintaining readability and SEO optimization. Let me know if you’d like any refinements!

Final Thoughts

Multistage fracturing is an innovative technology in the oil and gas industry, opening up huge reservoirs of energy trapped behind tight formations. With the well segmented into several isolated stages, operators can optimize production while decreasing cost and lowering environmental impacts.

With the advancement in technology, multistage fracturing will remain a vital part in addressing the world’s energy needs with high efficiency.