Real-time Data Analytics in Well Intervention

In today’s oil and gas industry, well intervention operations are becoming increasingly complex. Real-time data analytics has become a revolutionary approach, allowing operators to make faster, more informed decisions during well intervention. Through the integration of advanced sensors, high-speed data processing and predictive algorithms, Real-time data analytics can provide practical insights that improve operational efficiency and safety.

Understanding Real-time Data Analytics in Well Intervention

Real-time data analytics involves capturing the data, processing it, and then analyzing data from wells as it’s produced, which permits immediate analysis and subsequent action. When it comes to intervention in wells it is the process of monitoring parameters like temperature, pressure and flow rates, as well as equipment performance, and vibration as well as interventions such as cleaning outs, stimulation or modifications to the completion are being implemented.

In contrast to traditional methods, in which data is analyzed after operation, real-time analytics allow operators to react to the changes in real-time. This is essential in preventing equipment malfunctions as well as optimizing performance of wells and also reducing non-productive time.

Key Technologies Enabling Real-time Analytics in Well Intervention

Understanding these technologies in real-time data analytics will provide insights into how operators can improve efficiency, safety and decision-making capability during well interventions.

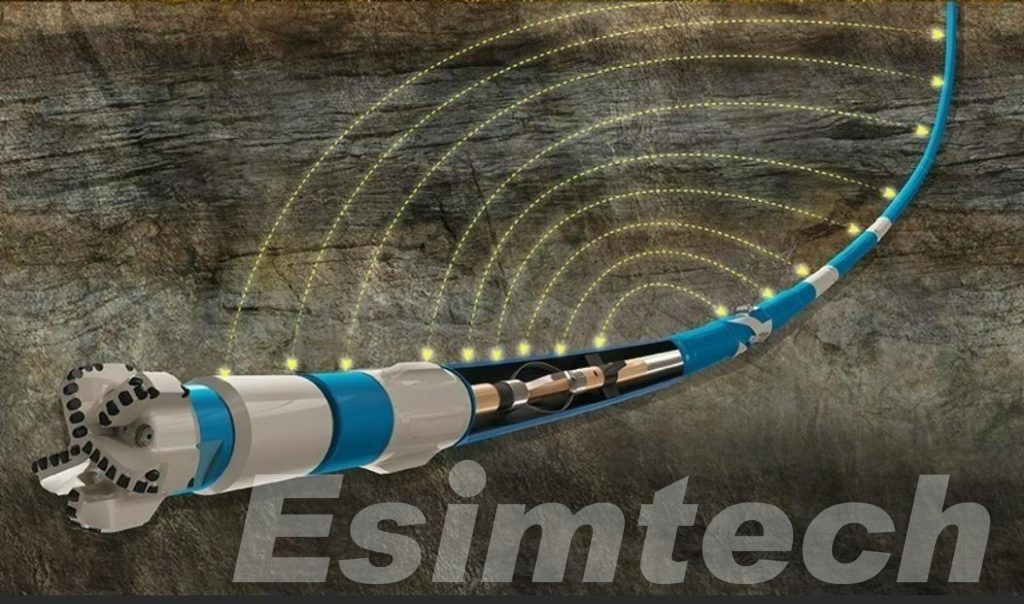

1. Advanced Sensors and Measurement Tools

The heart of real-time analytics is the instruments and sensors that collect critical well data. Modern downhole sensors can measure temperatures, pressure flow rate, pressure and vibration with a high accuracy, delivering constant streams of information throughout interventions. Innovations in fiber optic sensing and MEMS (Micro-Electro-Mechanical Systems) allow for real-time detection of subtle changes in well conditions, enabling operators to respond to anomalies before they escalate. Surface sensors are complemented by the downhole measurement by observing the performance of equipment and operating parameters above the ground.

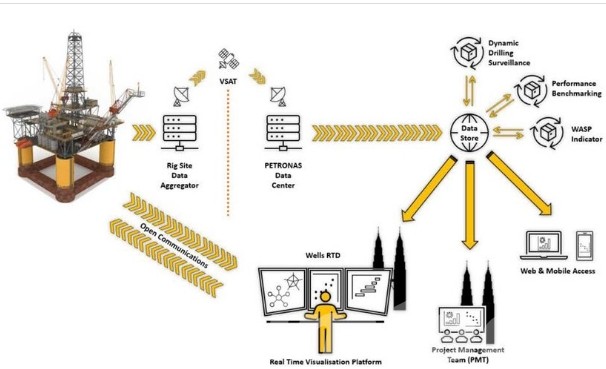

2. IoT Connectivity

The seamless transmission of data is vital to enable real-time analytics. it is the reason why Industrial Internet of Things (IIoT) is a key element for connecting sensor, devices, or control system. IoT networks enable data from a variety of sources to be merged and shared in real-time, regardless of whether the well is offshore or in an offshore environment. This connectivity lets decision makers have a complete view of the entire operation, allowing quick response to changes in conditions.

3. Edge and Cloud Computing

Processing the huge amount of data generated by well operations require both local as well as central computing power. Edge computing lets data be processed at the well’s location, thereby making it faster and more efficient in operational decision-making. Cloud computing however offers scalable resources to support more sophisticated analyses, storage of long-term data as well as advanced modeling. Combining edge computing and cloud computing makes sure that the operators are able to act swiftly and benefit from deep analysis of large data sets.

4. Predictive Analytics and Artificial Intelligence

Artificial intelligence (AI) and machine learning improve real-time analytics, identifying patterns and anticipating potential problems before they arise. For instance, AI can forecast equipment wear, spot pressure anomalies, or anticipate the likelihood of disruptions in flow based on the historical and current data. These predictive capabilities transform interventions from being a reactive approach to a proactive one decreasing the time spent on inefficient work, avoiding costly failures, and enhancing the strategies for intervention.

5. Data Integration and Visualization Platforms

The ability to collect and analyze real-time data can only be effective in the event that operators can understand it swiftly. Data integration tools that are advanced integrate data from a variety of devices, networks of IoT and computing systems into one interface. Visualization tools provide complex data sets in easy-to-read formats like dashboards, graphs, or 3D models, which allow engineers to make informed choices quickly.

Key Applications of Real-time Analytics in Well Intervention

Knowing the important applications of real-time data analytics can provide an understanding of how real-time data analytics transforms well intervention practices.

1. Well Cleanouts and Debris Management

Well cleanouts are vital to getting rid of scale, debris or paraffin deposits which can hinder production. Real-time analytics allows operators to keep track of the parameters like flows, pressure and concentration of solids as cleaning is carried out. This instant feedback enables fluid adjustments, which prevents blocks, reducing wear and tear on equipment and ensuring that the cleaning process can be completed quickly and without delays.

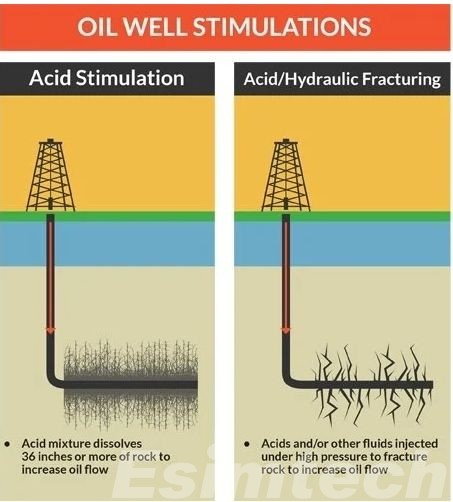

2. Stimulation Operations

Well stimulation activities, like the acidizing process and hydraulic fracturing require exact control of chemical treatments, as well as flow rates. Real-time analytics provides continuous information on these vital parameters that allow operators to adjust treatments as they go. This increases contact with the reservoir improves production, increases production, and reduces the risk of formation damage, and reduces the chance of operational issues.

3. Fishing and Milling Operations

Milling and fishing involves removing stuck equipment or clearing obstructions from the wellbore which is hazardous and time-sensitive. By monitoring vibration, torque and the load condition in real-time operators are able to spot possible issues in advance and then take corrective action. This minimizes the risk of failures in the tool, reduces ineffective time, and improves the safety of these complicated interventions.

4. Completion Optimization

Well completion, including plug placement, perforation and installation of equipment, benefit greatly from real-time monitoring. Temperature, pressure, and data on flow are continuously monitored making sure that each process is carried out effectively. Operators are able to respond immediately to any deviation from the expected behaviour, increasing the efficiency and decreasing the possibility of causing damage to the formation.

5. Predictive Maintenance and Equipment Management

Real-time analytics can be instrumental in the prediction of well intervention maintenance to prevent wells. Through analyzing the performance of equipment and the condition of the tool continuously the possibility of problems can be identified and dealt with before they grow. This proactive approach prolongs the life of crucial tools, reduces maintenance costs, and decreases the amount of downtime that is caused by operational issues.

6. Risk Mitigation and Decision Support

Beyond efficiency in operation Real-time analytics improves the process of making decisions and managing risk. Combining different data sources into one coherent view lets operators identify potential problems, such as problems with equipment, pressure rises or instability in formation. This capability allows engineers to make informed choices quickly, reducing risks to operations and ensuring smoother operations.

How Simulation Technologies are Used for Optimizing Real-time Analytics in Well Intervention

Through creating precise digital representations of well conditions and equipment behavior, simulation technologies enable operators predict potential issues, optimize operational parameters and make informed decisions. Combining simulation process with real-time data analytics transforms well intervention from a reactive process into a proactive and highly efficient operation.

Digital Twins for Well Behavior Modeling

A single of the more significant applications of simulation technology in well interventions can be the development of digital twins. Digital twins are a virtual representation of the well that includes its reservoir’s characteristics, the wellbore’s geometry, and the installed equipment. Through constant updating of the model using real-time information, operators can create different intervention scenarios, forecast the outcome of specific actions, and determine the possible risks prior to taking them into the field. This method allows for precise plan and instant reaction to changes in well conditions.

Real-Time Flow and Pressure Simulations

Simulating flow dynamics and pressure behaviour in real-time helps operators know how their actions, like cleanouts or stimulation treatments, can impact the well. Through the integration of sensors in fluid dynamics simulation models real-time simulations are able to predict pressure fluctuations as well as flow restrictions and possible damage to the formation. This allows operators to alter the rate of circulation as well as pump pressures and chemical treatments in a matter of minutes, thus decreasing operational risk and increasing overall efficiency in intervention.

Equipment Performance and Stress Analysis

Well intervention simulators are also utilized to track and predict the efficiency of intervention tools and equipment. Virtual models of downhole equipment, tubing and other surface equipment can be constantly updated with current information such as the torque, vibration and loads. Simulations can help to predict possible problems or bottlenecks in operation which allows for maintenance and adjustments that are proactive or even replacement of the tool prior to the occurrence of problems.

Scenario Planning and Decision Support

Real-time simulation lets operators try out a variety of “what-if” scenarios without disrupting running operations. Through modeling different interventions and analyzing the potential results, operators can choose the most effective strategy. This is especially useful for complex operations like milling or fishing where unpredictability of conditions could dramatically affect safety and efficiency. Simulation-driven decision support reduces the risk of accidents and ensures that actions are carried out with a high degree of accuracy.

Integration with AI and Predictive Analytics

The integration of simulation technology along with Artificial Intelligence (AI) and prescriptive analytics can further improve the speed of decision-making in real time. AI algorithms can be trained to use the historical and current information to refine models of simulation which improve precision of forecasts. This integration lets operators anticipate behavior patterns that are well-known, optimize the parameters of intervention, and avoid problems before they become serious.

Challenges and Future Solutions for Real-time Data Analytics in Well Intervention

| Challenges | Description | Future Solutions |

| Data Integration Complexity | Mixing data from various sources, such as old and newer technology, is challenging. | Creation of unified data platforms and standard protocols to seamlessly integrate various data streams. |

| Connectivity Limitations | Remote well sites usually have a low bandwidth or aren’t reliable connection to the network. | Innovative IoT systems, satellite communications along with edge computing allow accurate and instantaneous data transfer. |

| Data Overload | Massive amounts of data could overwhelm the operators and make it difficult to gain actionable insights. | Automated analytics, AI-driven filters and visualization tools to concentrate on the most important data to make decisions. |

| Cybersecurity Risks | Monitoring systems that are real-time are susceptible to hacker access or cyber-attacks. | Security protocols that are enhanced encryption, encryption, with secure cloud-based solutions that protect sensitive operational information. |

| Skilled Workforce Shortage | Operators require expertise in data analytics as well as intervention engineering. | Programs for training, AI-based decision-support and powerful visualization platforms that help bridge the gap in skills. |

| High Implementation Costs | Real-time analytics can require a significant capital investment. | Flexible, scalable solutions and cost-sharing models to make the adoption more financially feasible. |

Summary

Real-time data analytics is revolutionizing well intervention by providing instant insights that drive safer, faster, and more efficient operations. As technologies like AI, IoT, and advanced sensors, continue to develop and improve, operators who leverage these tools will have significant competitive advantages in optimizing well performance and reducing operational risks.