Well Control Strategies in Carbon Capture and Storage (CCS)

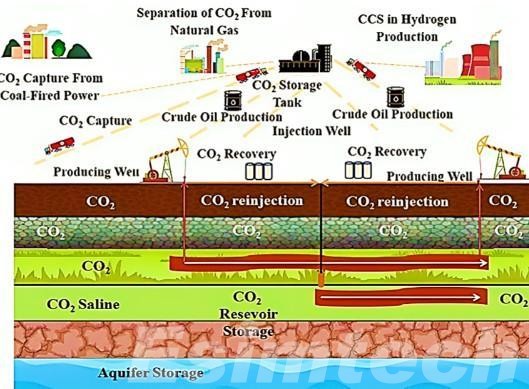

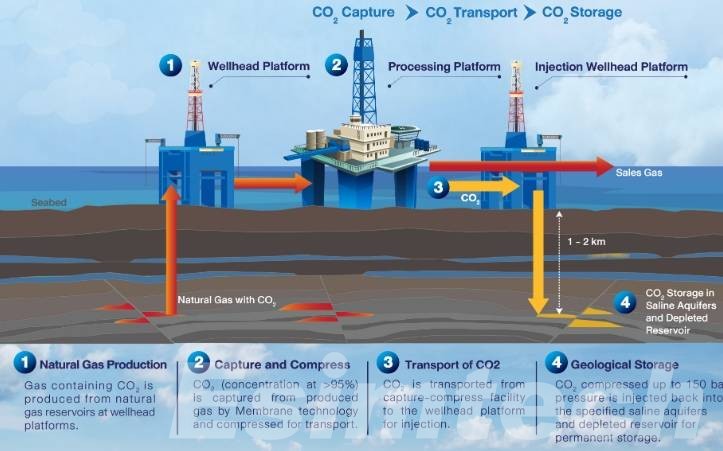

Carbon Capture and Storage(CCS) is an essential technique for reducing greenhouse gas emissions through the capture of CO2 from sources of industrial sources and storing it deep underground in geological formations. However, ensuring the safe and secure storage of CO2 demands robust well control strategies for maintaining safety operation, preventing CO2 leaks and ensuring storage integrity.

Understanding Well Control in Carbon Capture and Storage (CCS)

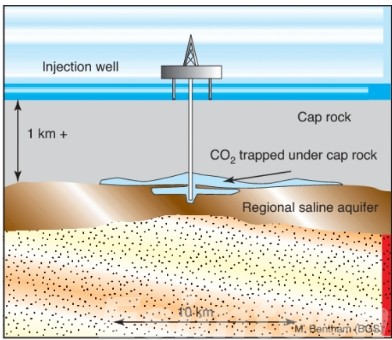

Well control refers to the set of measures and practices designed to manage pressures and flows during well operations, ensuring that the injected CO2 remains contained within the designated storage formation. For Carbon Capture and Storage, well control is different from standard oil and gas operations because:

- CO2 is usually introduced in supercritical form which makes it extremely pressurized and able to migrate in the event of improper management.

- Storage formations are diverse and include depleted reservoirs as well as saline aquifers and coal seams that are unmineable each with its own permeability and pressure characteristics.

- Long-term storage involves monitoring for many decades after injection, in contrast with the extraction of hydrocarbons where wells are typically shut down earlier.

Challenges of Well Control in Carbon Capture and Storage (CCS)

| Challenge | Description | Impact on Well Control |

| CO2 Behavior | Supercritical CO2 is able to dissolve in water of formation and then react chemically with cement and rock. | Could weaken the well’s integrity and cause leaks. |

| Long-Term Containment | CCS wells have to be protected for decades, or even hundreds of years. | It requires a sophisticated monitoring system maintenance and long-lasting materials. |

| Geological Variability | Storage formations are usually heterogeneous and have varying permeability and profiles of pressure. | This increases the uncertainty of the management of pressure and CO2 migration control. |

| High Injection Pressure | CO2 is injected with high pressures, allowing it to remain in supercritical state. | The possibility of a fracture that is too high which could cause cracks in the formation or leakage. |

| Corrosion and Material Degradation | CO2 is corrosive, particularly when combined with formation water to create carbonic acid. | Casings can degrade, as well as cement and other components of wells in time. |

| Monitoring Complexity | Storage that is long-term and a deep one requires complete surveillance. | It requires the integration of sensors from downholes as well as surface monitoring and geophysical methods. |

| Emergency Response Preparedness | Unexpected leaks or pressure surges could happen. | Needs to have robust contingency plans as well as fast shut-down procedures. |

Solutions for Effective Well Control in Carbon Capture and Storage (CCS)

1. Robust Well Design and Construction

The well design is at the heart of successful Capture and Storage operations. Wells are constructed with multiple casing strings in order to separate different geological zones and high-quality cementing is utilized to seal the bore, to stop CO2 from moving. Selecting corrosion-resistant materials is essential, since supercritical CO2 reacts with water to create carbonic acid. This could lead to the degradation of traditional components of a well. A well designed properly will ensure the safety of operations and the long-term confinement of CO2 injected.

2. Pressure and Flow Management

The control of reservoir pressure is an essential element in CCS controlling the flow of water. Injection pressures should be closely monitored to prevent them from exceeding the threshold for fracture in reservoir formations, and this may cause damage to the confinement. The flow rates are controlled to ensure that CO2 is properly incorporated into the reservoir. Furthermore pressure relief systems as well as emergency shut-in systems provide crucial security in the event unexpected conditions, while ensuring security in all times.

3. Advanced Monitoring and Surveillance

Continuous monitoring is vital to detect potential problems early and ensuring control over the CO2 wells. Sensors in the downhole measure temperatures, pressure, and CO2 saturation at a real-time rate and help detect leaks or any deviations from the wellhead. Monitoring techniques for seismic and geophysical methods follow the flow of CO2 within the storage structure, allowing operators to react quickly to any alterations and guarantee an ongoing, long-term stifling.

4. Ensuring Long-Term Well Integrity

The maintenance of well integrity throughout the lifespan of the Capture and Storage project is essential. Inspections regularly, tests for pressure and pre-planned maintenance allows the early detection of any casing degrading, cement weakening or other possible failure points. This proactive approach aids in maintaining control and reduces the risk of CO2 movement over a period of many decades or even centuries which is vital to the long-term viability of Capture and Storage.

5. Emergency Preparedness and Response

Even with a robust designs and monitoring systems, CCS wells must be ready for any unexpected event. Planned emergency response strategies include swift shut-in procedures, blowout prevention devices specially designed for CO2 injection and strategies to mitigate leaks like re-cementing or reinjection. With the help of contingency plans the operators are able to quickly stop the effects of environmental risks and avoid any anomalies.

6. Integration of Digital Technologies

Digital technologies that are emerging are changing well control in Capture and Storage. Predictive modeling, digital twins and AI algorithms can help optimize the injection strategy, pressure management and risk evaluation. These tools let operators predict the likelihood of failures to wells and adapt operations in a timely manner improving security and efficiency. Together with real-time monitoring digital integration, it provides an extensive solution to controlling wells.

How Simulations are Used for Optimizing Well Control Strategies in CCS

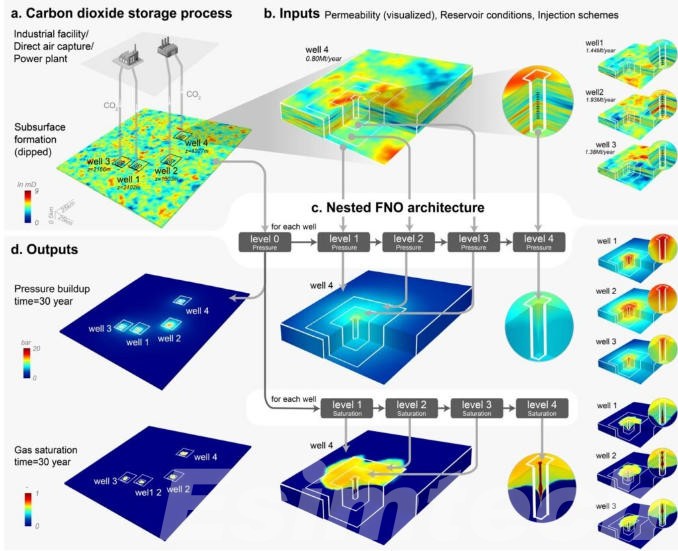

Simulations for Carbon Capture and Storage are computational models that simulate the CO2 behavior within the wellbore and the sedimentary storage. These models give a complete understanding of the dynamics of pressure, CO2 flow patterns, and the interactions between formation material. Through oil and gas simulation technologies, operators are able to anticipate the possibility of problems, like overpressure events, CO2 movement pathways, and impacts on well integrity, allowing preventive measures to be planned in advance.

Modeling Reservoir and Wellbore Behavior

A precise simulation of the reservoir’s behavior is crucial for the safety of CCS operations. Reservoir models use geological information such as porosity, permeability and stratigraphy to forecast the way CO2 will flow through the formation. Wellbore models simulate the behaviour of CO2 when it moves through the injection well, considering changes in temperature, pressure drops and possible chemical interactions. The simulations assist operators in optimizing injection rates and pressures in order to reduce the chance of leaks or fractures in the formation.

Pressure and Flow Optimization

One of the main uses for simulations within CCS is flow and pressure management. By simulating various injection scenarios, operators are able to identify the safest injection pressure for a particular configuration and also develop flow rates to stop excessive pressure. Simulations can also be used for evaluation of procedures for emergency shut-in as well as the assessment the effectiveness of relief mechanisms in various operating conditions, and ensuring that control strategies for well-being are reliable and efficient.

Risk Assessment and Contingency Planning

Emergency training simulations are a proactive approach to risk evaluation. Through modeling possible failure scenarios, for example casing corrosion or cement degradation engineers can analyze the effects on the integrity of wells and CO2 encapsulation. This allows the creation of contingency strategies and mitigation plans before problems occur. Furthermore, simulations can anticipate long-term CO2 emissions which helps to secure storage over years or even centuries.

Simulation-Driven Well Control

Making use of well control simulation systems for Carbon Capture and Storage has multiple advantages. They decrease the chance of operational failures as well as CO2 leaks. They also improve the efficiency of injection processes and improve the safety of storage over time. Simulations can also reduce costs by eliminating the necessity for trial and error on the field and allowing more informed decisions in complicated geophysical settings. Simulation-driven strategies ultimately boost confidence in the quality and long-term viability for CCS projects.

Future Outlook of Well Control in Carbon Capture and Storage (CCS)

Innovations in technology, materials and monitoring strategies are likely to revolutionize well control in Carbon Capture and Storage, enhancing the safety and efficiency of operations.

Advancements in Well Design and Materials

The future of well control in Carbon Capture and Storage will be determined by advancements in well design as well as construction material. Innovative corrosion-resistant alloys and CO2-tolerant cements are currently being developed to withstand the demanding chemical and pressure conditions that come long-term CO2 storage. Modern multi-layer casing design and sealing techniques will decrease the possibility of leaks, giving more confidence in the quality of storage wells for many decades, or even for decades.

Enhanced Pressure and Flow Management

Future plans for well control can benefit greatly from advanced techniques for flow and pressure optimization. Sensor networks and advanced simulations can provide operators with precise insight into the behavior of reservoirs and allow for dynamic control of pressures and injection rates. This will reduce the risk of formation fracturing, overpressurization or CO2 migration and can help improve efficiency for massive-scale CCS projects.

Integration of Advanced Monitoring Technologies

Monitoring technology will continue to develop, offering greater precision and coverage. Innovative technologies like fiber optic sensing that is distributed and downhole chemical sensors as well as enhanced seismic imaging, will help in the detection of changes in pressure leaks, CO2 patterns of migration. Integration technology into unidirectional monitoring platforms will enable better oversight and faster responses to abnormalities, increasing long-term security for storage.

Long-Term Risk Management and Regulatory Compliance

As Carbon Capture and Storage operations grow the need for risk management over time is becoming more important. Future strategies for controlling wells include the use of predictive maintenance, integrity assessment and frameworks for regulatory compliance that stretch across decades. Combining technological solutions with solid tracking and reports, CCS projects can demonstrate environmental safety as well as operational dependability to regulators, stakeholders and the public.

Collaboration and Industry Standards

The future of well control in Carbon Capture and Storage is going to depend on the collaboration of industry experts and standardized practices. Sharing of knowledge among researchers, operators and regulators will boost the pace of innovation and enhance safety protocols. Standardized guidelines for the well construction, monitoring and emergency responses will make sure that Carbon Capture and Storage projects comply with high quality and safety standards across the globe.

Summary

Well control in Carbon Capture and Storage is critical to safely and effectively sequester CO2, minimizing environmental risk while enabling large-scale carbon reduction. Through the integration of robust well design, pressure management, continuous monitoring, emergency response planning and long-term integrity strategies, operators can make sure that CCS is able to fulfill its function in reducing global carbon emissions. As technology advances, innovations in materials and predictive modeling will further strengthen well control strategies, improving the safety and reliability for CO2 storage.