How to Optimize Costs in Well Logging

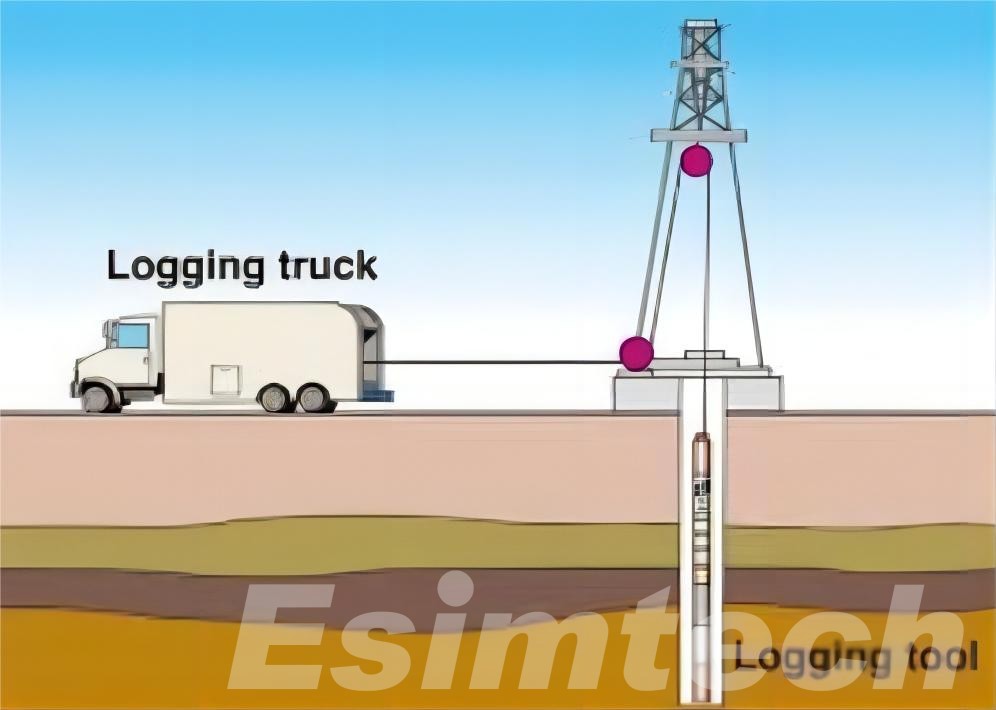

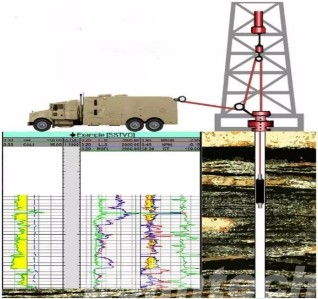

The oil and gas industry relies on well logging to provide vital data about geological formations and fluid properties. It also provides information about the overall characteristics of the well. Well logging is expensive due to the complexity of equipment, the data acquisition and the time needed for detailed measurements. Optimizing costs in well logging is a key goal for both operators and service providers as the industry is under increasing pressure to cut costs while maintaining operational efficiency. This article focuses on the topic of how to optimize costs in well logging, exploring effective strategies for cost optimization while balancing budget and performance of well logging, as well as maximizing the value collected.

Cost Drivers in Well Logging

This chart provides the key cost factors involved in well logging operations, providing insight into areas where cost optimization efforts can be targeted.

| Cost Driver | Description |

| Equipment and Technology Prices | Cost of special logging tools, downhole sensors and instruments, including maintenance, deployment and cost. |

| Expertise and Labor | Cost of personnel required to operate equipment, analyze information, and make decisions in logging operations. |

| Delays in Time and Operations | The amount of time it takes to complete logging, including delays caused by equipment failure, bad weather or logistical problems. |

| Data Interpretation and Processing | Costs associated with large data volumes, software analysis and expertise in interpretation. |

| Logistics and Mobilization | Transporting personnel and equipment to and from the site of drilling, as well setting up operations. |

| Non-Productive Time (NPT) | The time spent in the process of well logging without progressing, usually due to equipment failures, operational inefficiency, or weather-related delay. |

| Well Complexity | The cost of drilling a well increases with the complexity. |

| Regulatory Compliance | Costs of ensuring that logging operations comply with industry standards and regulations. |

Key Strategies to Effectively Optimizing Costs in Well Logging

1. Selecting The Right Well Logging Tool

The best way to reduce well logging costs and maximize profits is by selecting the right well logging tools for the specific operation.

This chart offers the most important factors to consider when choosing the right tools for well logging. It will help operators make informed choices that balance performance, costs, and operational requirements.

| Factor | Description | Impact of Tool Selection |

| Well-Objectives | The specific objectives of the well-logging operation such as formation evaluation or reservoir characterization. | Determine the type of tool required (e.g. resistivity logging, porosity logging or gamma ray logging). |

| Well Type and Complexity | The well’s characteristics, including depth, pressure and temperature, as well as the type of reservoir. | This influences the selection of specific tools for well conditions (e.g. high pressure logging, deepwater logging). |

| Data Resolution Requirements | The amount of detail that is required in the measurements. For example, high-resolution images or large-scale surveys. | The guide helps you choose between basic and advanced logging equipment (e.g. wireline logging vs. LWD logging). |

| Tool Compatibility | Integrability of the tool with other data logging systems or equipment. | Data collection is seamless and compatible with other systems. |

| Operational Environment | Conditions of the operating environment such as temperature and pressure. | Determine the type of tool needed for extreme situations (e.g. high-temperature, corrosion-resistant, tools). |

| Budget and Cost Limitations | Financial limitations are a major concern. | The selection of tools is influenced by the cost-effectiveness, and functionality required. |

| Tool Availability and Lead Time | The time required to mobilize and the availability of certain tools. | If urgent logging is required, it will impact the timeline and decision making. |

| Speed up and Efficiency | It is important to reduce the amount of non-productive time by accelerating data collection and deployment. | This guide helps you choose faster or more automated tools to reduce operational delays. |

| Data Accuracy and Precision | It is important to ensure the accuracy and reliability of measurements made by the tool, particularly for critical reservoir evaluation. | When precise measurements are required for decision making, choose tools with high accuracy. |

| Maintenance | This includes factors like wear resistance and repairability. | Affects the long-term costs of operation and ensures that tools are fit for extended use, with minimal downtime. |

2. Leveraging Integrated Logging Solutions

Integration of multiple logging services into one service package can result in significant cost savings. In the past, different logging activities were performed independently, and each required a separate mobilization. This can result in increased costs and reduced efficiency. By combining wireline logging with logging while drilling, for example, operators can minimize downtime and reduce trips into the well.

Integrated solutions reduce the need for separate, multiple logging operations. It not only reduces costs, but it also increases operational efficiency by allowing faster data collection and decision-making in real-time. Integrated solutions can also help operators understand the relationship between different measurements and improve the quality and usability of data.

3. Reducing Non-Productive Time (NPT)

The cost of non-productive time is a major factor in the well logging process. NPT is time spent on site that does not contribute directly to the logging process. Equipment failures, weather issues or poor team coordination can cause delays that add up to increased operational costs.

Operators can reduce NPT by focusing on preventive maintenance. They should also monitor equipment in real time to identify any potential problems before they cause downtime. Automated systems can be used to monitor equipment and collect data, reducing human error. A careful plan and clear communication among all the teams involved can also help to avoid unnecessary delays.

4. Optimizing Data Acquisition and Interpretation

The cost of well logging is directly affected by the efficiency of data collection. The less time and resources are spent on interpreting and re-acquiring measurements, the more accurate and rapid data collection is. Data transmission in real-time and automated data collection systems can improve data quality and speed. Operators can reduce labor costs by reducing the amount of manual data entry.

Investing in data interpretation software that is advanced can also help to streamline the process of analysis. Modern software tools include features like automated quality control and real-time visualisation, which can help speed up interpretation and reduce the need to manually intervene. These tools allow operators to make better decisions more quickly, resulting in quicker turnarounds and lower costs.

5. Using Well Logging Data across Multiple Applications

Another effective way to optimize costs is by maximizing the use of data from well logging across multiple applications. The data collected for a particular purpose (such as formation evaluation) can be used for other purposes, such a reservoir modeling, wellbore analysis, or geosteering. Operators can reduce future data acquisition costs by repurposing their well-logging data.

This multi-use strategy ensures that investment in logging operations will provide value beyond its initial purpose. Integrating well logging with other information sources, such as production or seismic data, can also provide a better understanding of the reservoir. This will lead to more informed decisions and efficient well management.

6. Collaboration with Third-party Service Providers

Third-party providers of logging services can provide significant cost savings for companies, especially those that do not have the resources or capabilities to perform certain logging tasks. The service providers have access to new technologies, equipment and expertise that can help reduce the capital expenditure required for specialized software and tools.

Partnering with an experienced service provider can help operators benefit from economies-of-scale, since these providers have the resources and expertise to handle large volumes of work at lower costs than their own teams. Operators should select a service provider that offers integrated services, real time data access and has a track record for reducing costs without compromising service quality.

7. Improving Planning and Project Management

To minimize costs, it is essential to have a well-planned and managed project. Operators can avoid potential problems and risks by developing a detailed and clear plan for every logging operation. It is important to ensure that all the necessary tools, personnel and resources are available before the operation begins.

Well-managed projects will have clear budgets and timelines. They also employ risk mitigation strategies to ensure that the project stays on budget and on schedule. By analyzing the results and costs of previous well logging projects, operators can refine their approach and identify further opportunities for optimization.

Emerging Trends in Optimizing Costs for Well Logging Operations

Automation and Digital Technologies

Automation and digital technologies will continue to influence the future of well logging. Oil and gas has already witnessed the rise of automated data collection, real-time monitoring and automated wellbore control. These technologies will become more sophisticated in the future, with AI, machine learning (ML), big data analytics, and artificial intelligence (AI) playing a key role.

Automation will reduce human error, and therefore the need for manual intervention. The real-time monitoring system will give continuous feedback, which allows for faster adjustments and reduces downtime. The overall efficiency of the well logging operation will improve. This will lead to a reduction in costs due to equipment malfunctions, delays, and inefficiencies.

Digitalization will facilitate the integration of different data streams and enable a holistic approach to well assessment. The data from various logging tools, geophysical surveys, seismic studies and production performance can be combined and analyzed seamlessly, reducing the requirement for redundant measurements. It will optimize costs and improve decision-making because operators can get a complete view of the subsurface.

Integration of Advanced Simulation Technologies

Cost optimization for well logging will be aided by advanced simulation technologies.

This chart gives a clear view of the different oil and gas simulation technologies that can be used to optimize well logging costs. From predicting well behavior, to improving maintenance strategy and increasing overall operational efficiency.

| Simulation Technology | Application of Well Logging | Cost Optimization Impact |

| Reservoir Simulation | Model reservoir behavior and fluid flows to predict well performance. | By providing better forecasts and saving time, it is possible to reduce the number of logging operations. |

| Wellbore Modeling | Simulation of fluid flow and wellbore geometry. | Reduces non-productive time and delays by identifying potential problems early. |

| Simulation of Logging while Drilling (LWD) | Simulates LWD performance during drilling operations in real time. | The use of tools is optimized based on the real-time situation, so that only the necessary tools are used, minimising equipment and operating costs. |

| Predictive maintenance Simulation | Modeling the performance and wear on logging equipment. | Predicts equipment failures before they occur, allowing proactive maintenance to reduce downtime and repair cost. |

| Data Integration and Analytics | Integrates well-logging data with seismic, production, and geological data. | Data interpretation is improved, which reduces the need for data collection, re-logging and more. This leads to better informed decisions, and cost savings. |

| Virtual Well Testing | Simulates different scenarios of well logging and operational conditions. | The most cost-effective approach to logging for a well is identified, which reduces unnecessary logging and optimizes data acquisition. |

| Operational Simulation | Simulates logging operations from planning through to execution. | Costs are reduced by improving efficiency, optimizing workflows and reducing delays. |

Adoption of Collaborative well Logging Services

In the future, collaborative service models will be more prevalent in well logging cost optimization. Well logging operators and service providers will collaborate more closely to create cost-effective and efficient logging programs. Collaboration models will enable better resource sharing, optimization of tools, and consolidation of services.

As an example, well-logging services can be combined with complementary services such as reservoir modelling, seismic interpretation or real-time monitor. Operators can lower costs by consolidating services and reducing the number of vendors. Shared services allow operators to use advanced technologies such as AI, data analytics and other sophisticated tools without having to invest heavily in proprietary systems.

In addition, service providers can offer flexible pricing models based on results and performance, as opposed to fixed fees for each individual service. This performance-based model will encourage service providers to optimize their operations and reduce costs. Both operators and service companies will benefit from this approach.

Sustainability and Environmental Considerations

The sustainability of well logging operations will be a major factor, both in terms of cost and environmental impact. Oil and gas companies will have to adopt more sustainable practices as regulations regarding emissions and waste management tighten. This could reduce costs. The use of energy-efficient tools and equipment as well as green technologies will reduce the impact of well logging while also lowering costs.

By optimizing the well logging process and reducing the required number of operations, companies can reduce their carbon footprint. The alignment of cost optimization and sustainability goals not only helps companies comply with regulations, but will also appeal to a market that is increasingly eco-conscious.

Summary

In order to optimize costs, well logging requires a careful balance between technology, time and resources. Operators can lower costs by choosing the right tools and integrating services. They can also reduce non-productive time and use advanced data processing systems. Adopting digital technologies, and using data from well logging for multiple purposes, can maximize the value of logging operations, which will lead to more cost-effective and efficient well logging.

Optimizing costs in well logging will continue to be a key aspect in the oil and gas sector as it continues to develop. This is important for maintaining a competitive edge and maximizing profitability. Operators can find cost-effective solutions through continuous innovation, strategic decisions and adoption of best practices.