How Oil Rig Simulators Enhance Well Control Certification

The oil and gas industry is well-known for its intricate operations and risky environments. One of the most crucial aspects of drilling is well control, which involves controlling pressure to prevent blowouts and uncontrolled releases of fluid. To ensure that personnel are prepared for the high-stakes situations, oil rig simulators have emerged as important tools for training and certification for well control.

The Importance of Well Control Certification

The well control certification is vital for the industry of oil and natural gas, to ensure the safety of workers, equipment, personnel, as well as the environment. It ensures that drilling and well-service professionals are knowledgeable and have practical experience to manage sudden pressure fluctuations and avoid blowouts. The certified personnel are better equipped to spot warning signs, act promptly, and keep control over the well, minimizing risk and ensuring compliance with regulations of the industry, like those issued through the IADC and IWCF. In the end, certification of well control is an essential element of effective and safe drilling.

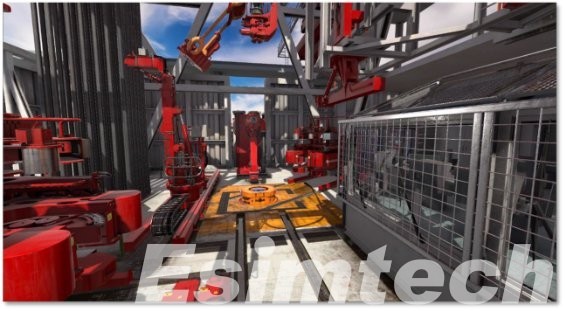

The Role of Oil Rig Simulators

Oil rig simulators play an essential role in training and certifying employees for safe and efficient drilling activities. They replicate real-world situations and emergency situations, they provide hands-on experiences in a safe, secure environment. They aid in understanding complex systems, increase decision-making under pressure, and ensure that students are prepared to face challenges in controlling wells. As a vital instrument in certification programs, oil rig simulators improve safety practices, increase the efficiency of operations, and ensure compliance with international standards for the industry.

Benefits of Using Oil Rig Simulators for Well Control Certification

Traditional methods of training, though important, are often incapable of preparing students for the unpredictable nature of real-world situations. This is why oil rig simulators are extremely useful by providing a secure, controlled, immersive, and safe environment to master methods of controlling wells.

1. Bridging Theory and Practice

Certification for Well Control requires more than merely theoretical understanding and requires the ability to deal with high-pressure conditions on the drilling rig. Oil simulators for rigs help provide this by giving learners a hands-on training experience that is akin to actual drilling procedures. They replicate everything from the equipment’s response to changes in formation pressure to ensure that trainees do not just understand the procedure but also can perform it efficiently.

2. Simulating Realistic Well Control Scenarios

One of the main advantages of oil rig simulators is their ability to replicate a broad range of realistic well control scenarios, including gas kicks or stuck pipe events, or the loss of circulation. Trainees need to recognize warning signs, follow the appropriate protocols for responding, and regulate the situation under pressure. This interactive training environment prepares them for the unpredictable problems that arise in real-world operations.

3. Improving Decision-Making and Reaction Time

In the context of simulation, students are able to feel the pressure and pressure of a managed event, without negative consequences in real life. This helps them sharpen their thinking skills and improve the speed of their reaction. These critical thinking exercises build confidence and competence–qualities essential for achieving certification and performing safely in the field.

4. Supporting Compliance with Certification Standards

Organizations such as the International Association of Drilling Contractors (IADC) and the International Well Control Forum (IWCF) have to conduct practical tests in their certification procedures. Oil rig simulators offer a safe, controlled, and standardized setting for evaluating the performance of potential candidates and ensuring that they are in line with the international security and competence standards.

5. Facilitating Team-Based Training

Well control is seldom an individual task. Effective response is dependent on the coordination of drillers, toolpushers, and mud engineers. Simulators facilitate teams to train, allowing several people to work in real-time. This encourages a strong sense of communication and collaboration, both of which are crucial during a live well-control event.

6. Enhancing Instructor Feedback and Assessment

Modern simulators come with built-in performance tracking features that allow instructors to observe their actions, spot mistakes, and provide thorough feedback. This approach is based on data and makes sure that students are not only evaluated on their final results but also their decision-making process and their procedural rigor.

Types of Oil Rig Simulators for Well Control Certification

| Type of Simulator | Description | Key Features |

| Drilling Simulator | Simulation of offshore and onshore drilling activities, with an emphasis on the control of wells. | Instant pressure responses, floor replica, kick detection roles for teams. |

| Well Intervention Simulator | It is used for training in Coiled tubing, wireline, and snubbing. | Pressure control equipment simulation, various intervention scenarios. |

| Workover Simulator | The focus is on the maintenance and servicing of well operations under pressure. | Prevention of blowouts, tubing handling Shut-in procedure. |

| Cyberchair Drilling Simulator | High-fidelity simulator replicating the most advanced chairs and rigs. | Joystick and touchscreen operations with integrated data systems, a real-looking user interface. |

| Portable Drilling Simulator | Mobile, lightweight solution to remote or classroom training. | Desktop or laptop-based, with a touch interface, few features, but highly adaptable. |

| Full Mission Simulator | An immersive training space with a rig that rotates at 360 degrees and controls a room replicating. | Multi-user setup, full-scale hardware audio-visual effects, and an Instructor station. |

| Virtual Reality (VR) Simulator | Utilizes VR headsets to create immersive rigs and processes. | Full immersion motion tracking, smooth interactivity, and remote-training capability. |

Technological Advancements in Oil Rig Simulators for Well Control Certification

The oil rig simulators have seen significant technological advances, which have made them more immersive, accurate, precise, and efficient in preparing drilling workers for situations that are high-risk. These advancements are revolutionizing how students acquire and demonstrate skills required by certification organizations like IADC and IWCF.

- High-Fidelity Simulation Environments

The most significant development is the creation of high-quality simulation environments. These systems accurately replicate real-world rig conditions–including pressure fluctuations, fluid dynamics, rig equipment behavior, and crew interaction. Users can experience a broad variety of well control scenarios, including kick detection and blowout prevention. They can also experience realistic visuals, sound effects, and rig reactions. These precise simulations can help in bridging that gap in instruction and fieldwork.

- Real-Time Data Integration and Feedback

Modern simulators incorporate real-time data analysis and acquisition tools. Trainees are immediately notified of their choices, allowing them to adjust and learn quickly. Instructors can track every step and access detailed logs and assess the performance of trainees against important indicators of performance (KPIs) pertinent to the standards for certification. Data-driven training can ensure each decision made is analyzed and enhanced, not merely practiced and then forgotten.

- Virtual Reality (VR) and Augmented Reality (AR)

Virtual reality and augmented reality technology have revolutionized the way that training is delivered. Oil rig simulations that use VR let users in an immersive 3D rig simulation in which they can learn procedures like shut-ins, as well as choke line control and kill sheet implementation. These tools improve the muscle memory and spatial awareness, which makes it easier for students to be able to adapt to real operating conditions in the rig. AR, on the other hand, can be used to overlay digital data on the physical tools for training, improving the realism of training without needing large-scale hardware configurations.

- Cloud-Based and Remote Simulation Platforms

Due to the increasing use of remote working and distributed teams for training cloud-based simulations have become more popular. They allow students to access well control education from any location, allowing companies to increase the size of certification programs across the globe. Cloud integration allows the control of versions as well as standardized training modules and central supervision of instructors, while preserving the integrity of the evaluation protocols.

- Customized Scenarios and Dynamic Modelling

Technological advancements have also led to increased possibilities for scenario design. Instructors are now able to design dynamic, custom simulations that are based on specific parameters for wells’ geological formations, the rig’s configuration, or even reports of incidents from the past. The ability to reproduce specific conditions at a particular site helps students prepare for the hazards they might face during their field jobs.

- Multidisciplinary Team Training

Nowadays, simulators allow integrated team-based training. This means that multiple users, such as supervisors, drillers, and mud engineers, can operate in the same virtual environment. This facilitates cooperation and communications under stress, both essential components of an effective response to control of wells. Modern simulators permit voice communication as well as coordinated decision-making and the execution of tasks based on roles in real-time.

- Integration with Certification Standards

Another important development is the integration of simulator systems with internationally recognized certification systems. The majority of simulators are built to replicate the exact specifications for IADC and IWCF tests, which ensures that the trainees are able to practice procedures exactly as they would be assessed. This makes it easier to pass the certification and increases the number of passes without compromising the accuracy of the assessment.

Final Thoughts

Oil rig simulators are revolutionizing well control certifications by providing secure, cost-effective, and highly efficient training solutions. With the advancements of VR, AI, and cloud-based learning, these devices make sure drilling employees are better equipped to handle emergencies and ensure operational safety.

For companies in the oil and gas industry, investing in advanced oil rig simulators is not just an option anymore, but is an essential element of the management of risk and compliance with regulatory requirements. Oil rig simulators are expected to be increasingly important as they help to shape a safer and productive drilling sector.

Esimtech is a leading provider of oil rig simulators, offering cutting-edge training solutions to companies in oil and gas. Specializing in high-quality, realistic simulators, Esimtech provides drilling simulation systems, simulators for well control, and well-intervention training. The simulators supplied by Esimtech are extensively utilized by oil and gas companies to make sure that employees comply with international certification standards like IADC and IWCF. With continuous innovations, customization, and technical support, Esimtech empowers oil companies to improve safety, performance, and operational capability in high-risk drilling environments.