Wireline vs. Coiled Tubing for Well Intervention: Choosing the Right Method

Well intervention in the oil and gas sector entails performing maintenance, repair and enhancement activities. Two common methods for well intervention are wireline and coiled tubing. Each option is different and has distinctive advantages, so it is important to understand their differences and common applications to optimize for specific well intervention tasks.

What is Wireline for Well Intervention

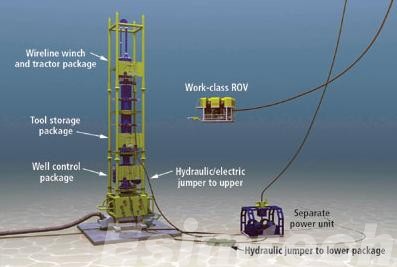

Wireline are systems on oil and gas wells interventions that use a steel wire to lower and raise tools in and out of the well and in the process get mud and other obstructions, as well as other equipment a wellbore. It can be well logging, monitoring, perforating, and or cleaning wellbore. Magazines that are reel wound use wireline.

Wireline interventions are either slickline which is used to provide mechanical services and other simple rope tasks or electric line e-line which has tools to work on or has communication equipment to control the downhole tools. Each wireline type is selected according to the specific intervention needs.

Advantages

- Cost-Effective: Wireline operations are one of the most inexpensive techniques when compared to other more elaborate intervention methods such as coiled tubing. Because of this, it becomes more economically viable for elementary well servicing and shallow well interventions.

- Quick Deployment: One of the most important aspects of wireline is the rapidity with which it can be executed. It takes less time to establish than other methods of intervention which is an advantage for short-duration tasks or emergency interventions.

- Precision and Accuracy: Wireline tools especially when it comes to logging and diagnostics, deliver accurate measurement and data acquisition. Being able to lower tools to an optimal level provides precise measurement.

- Minimal Surface Equipment: Wireline operations require less than normal to be operated which is well suited for operations within the cramped quarters of a rig.

- Versatility: Wireline can perform a myriad of tasks ranging from diagnostics, logging and wellbore maintenance interventions such as perforation, tubing recovery and continuous pressure measurement.

- Low Risk of Formation Damage: Wireline interventions are more likely to avoid causing wellbore and formation damage because their methods are gentle and the tools employed are lightweight. This is unlike most other intervention techniques which are more damaging.

Limitations

- Depth and Wellbore Limitations: Wireline is often is not applicable to very deep or highly deviated wells. It is useful in straight or slightly deviated wells, however, it struggles to perform efficiently in more complex well configurations, in particular, at greater depths.

- Limited Pressure Capability: Wireline systems do not function in high-pressure environments, which eliminates their usability in deep well stimulation, acidizing, and other pressure-sensitive operations.

- Tool Versatility in Operation Complexities: Even though wireline is great when it comes to basic interventions, such as logging, monitoring, and perforating, it is not always the most suitable for the more complex tasks that need continuous fluid circulation, such as acid treatments or fishing operations.

- Restricted Intervention Capability: Wireline tools generally cannot deploy larger, more powerful tools that are essential for more advanced well interventions. More powerful stimulation or cementing tools, for instance, require coiled tubing or other means.

- Risks of Wireline Failure: There is the potential for wireline systems to experience mechanical issues, such as the wireline snapping or derailing in the wellbore, which can halt the operation and introduce additional downtime for remedial activity.

Common Applications

This chart provides the main wireline applications and the tools commonly used in each.

| Application | Description | Tools Used |

| Well Logging and Diagnostics | Acquiring real-time data about the formation, pressure, temperature, and wellbore characteristics. | Gamma ray logs, resistivity logs, neutron porosity logs, pressure/temperature sensors. |

| Well Perforation | Creating holes in the well casing to allow fluid flow between the reservoir and wellbore. | Perforating guns, shaped charges. |

| Pressure and Temperature Monitoring | Monitoring pressure and temperature at various depths to assess well conditions. | Memory gauges, real-time pressure/temperature sensors. |

| Tubing and Equipment Retrieval | Removing stuck or damaged equipment or tools from the wellbore. | Jars, overshots, fishing tools. |

| Wellbore Cleaning | Removing debris, scale, or other obstructions from the wellbore to maintain flow and prevent blockages. | Scrapers, brushes, wash tools. |

| Plug Setting | Setting plugs in the wellbore for isolation, abandonment, or pressure testing. | Cement plugs, inflatable packers, mechanical plugs. |

| Slickline Services | Performing lighter mechanical operations such as tool retrieval, setting packers, and performing simple maintenance tasks. | Slickline tools (fishing tools, mechanical jars, plugs). |

What is Coiled Tubing for Well Intervention

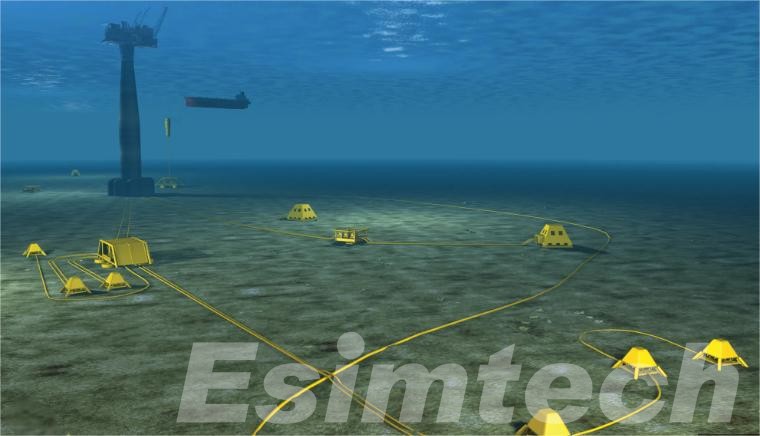

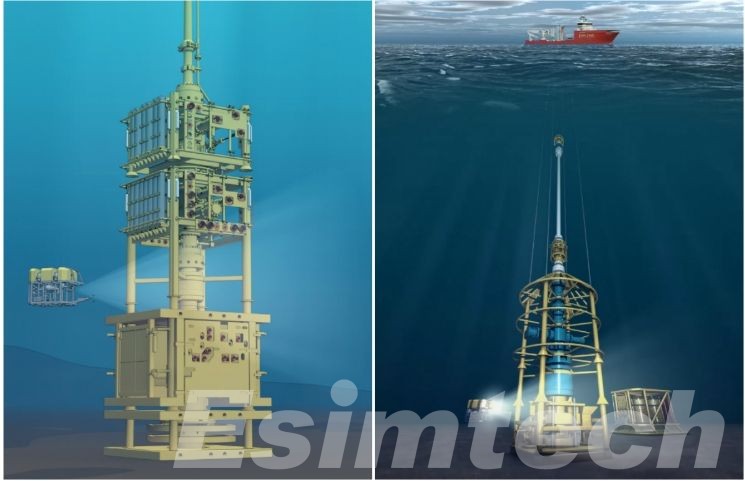

Coiled tubing refers to a continuous length of flexible steel tubing that is spooled onto a large reel and used in oil and gas well interventions. Coiled tubing can handle a broader range of operations and is ideal for deeper, more complex well interventions. It allows for the continuous flow of fluids and provides the ability to perform operations like stimulation, wellbore cleaning, and tool deployment without needing to pull out of the hole, making it particularly useful for high-pressure environments. Coiled tubing is deployed into the well using a hydraulic pumping system, and it can be inserted or retrieved from the wellbore while keeping continuous fluid flow, such as in wellbore stimulation operations. This makes it a highly versatile method for a variety of well interventions.

Advantages

- Continuous Flow of Fluids: Coiled tubing allows for continuous circulation of the fluid, which is important in operations such as wellbore cleaning, acidizing, and well stimulation. The ability to inject fluids without interruptions is important for maintaining pressure and achieving effective treatments.

- Versatility: Operators can perform a wide range of coiled tubing operations including pressure control, well cleaning, fishing, and plug setting, allowing them to do multiple interventions with the same equipment.

- High Pressure Handling: Compared to wireline, coiled tubing systems can handle higher pressure, making them appropriate for high pressure operations like hydraulic fracturing and acidizing treatments.

- Real Time Monitoring: Pressure, flow rates, and other parameters can be measured in real time during coiled tubing operations, giving operators data to monitor the pressure interventions.

- Efficient Deep-Well Intervention: Coiled tubing can access deep, deviated, and complex wells that wireline cannot. The flexibility of the coiled tubing makes it ideal for difficult or remote zones in deep wells.

- Multiple Tools Deployment: Operating coiled tubing allows the deployment of multiple tools for different tasks (e.g. perforating, cementing, fishing, etc) without removing the string, increasing efficiency.

- Wellbore Pressure Control: Coiled tubing can control the pressure of the wellbore during operations that require fluid control and pressure management like stimulation or production enhancement.

Limitations

- Higher Costs: Coiled tubing is often costlier than wireline interventions. The reason is due to the equipment, the intricacy of operations, and the necessary provisions of customized rigs and personnel.

- Equipment Size and Weight: Compared to wireline, coiled tubing units need more and bigger complicated surface equipment. This challenges the practicality of a site when it is small, and they do not suit straightforward interventions well.

- Setup Time: Coiled tubing operations take a considerably larger amount of time to prepare. Because there is more equipment to prepare and position, that results in time to lengthen the intervention.

- Operational Complexity: There is more involvement in Coiled tubing operations than the others. That leads to a rather higher profile of operational risks when it comes to their potential challenges.

- Limited Tool Size: Since there are various tools that coiled tubing can deploy, it is not a surprise the MagTubing would struggle to deploy the larger or heavier tools. That is a problem needed in more complicated operations, especially in very deep well drilling or large well stimulation..

- Risk of Coil Damage: The length of coiled tubing is especially vulnerable to support issues. The challenges in the well conditions tend to cause issues and the tubing can easily become kinked, fatigued, or break.

Common Applications

Coiled tubing is used for a broad range of applications in well intervention, especially in deep, high-pressure, and deviated wells.

| Application | Description | Tools Used |

| Well Stimulation (Acidizing & Fracturing) | Coiled tubing is used to inject fluids into the wellbore under pressure to enhance reservoir production by increasing permeability. | Acid injection units, hydraulic fracturing tools. |

| Wellbore Cleaning | Coiled tubing is ideal for cleaning out debris, scale, or blockages in the wellbore, ensuring smooth fluid flow. | Scrapers, wash tools, jetting tools. |

| Fishing Operations | Coiled tubing can be used to retrieve lost or stuck tools, tubing, or equipment from the wellbore. | Fishing tools, overshots, jar assemblies. |

| Cementing and Plugging | Coiled tubing is used for cementing operations and for setting plugs to isolate zones within the wellbore. | Cementing plugs, packers, inflatable plugs. |

| Pressure Control | During operations like fracturing or stimulation, coiled tubing can be used to control wellbore pressure and manage fluid circulation. | Pressure control equipment, valves, pumps. |

| Well Logging | Coiled tubing can be equipped with logging tools for real-time data collection to assess the wellbore condition. | Pressure and temperature gauges, logging instruments. |

| Coiled Tubing Drilling | Coiled tubing can be used for small-scale drilling operations or to assist in well deepening, particularly in wells with complex geometries. | Coiled tubing drilling tools, drill bits. |

| Hydraulic Isolation | Coiled tubing is used to isolate specific zones within the wellbore for targeted treatments like zonal isolation or selective perforation. | Isolation packers, mechanical plugs. |

Key Differences Between Wireline and Coiled Tubing for Well Intervention

This chart offers the major differences between wireline and coiled tubing, helping to illustrate which well intervention method might be better suited for specific well conditions and tasks.

| Feature | Wireline | Coiled Tubing |

| Flexibility | Rigid, limited flexibility. | Flexible, can navigate curved or deviated wellbores. |

| Depth Capacity | Suitable for shallow to moderately deep wells. | Ideal for deep, complex, or deviated wells. |

| Pressure Handling | Limited ability to handle high-pressure environments. | Designed to handle high-pressure operations, such as fracturing. |

| Tool Deployment | Tools are lowered via a single wire. | Continuous tubing allows for various tools to be deployed while circulating fluids. |

| Size and Weight | Smaller, lighter equipment. | Larger, heavier equipment, requiring more surface space. |

| Operational Speed | Faster deployment for simpler tasks. | Slower setup time but suitable for more complex operations. |

| Tool Versatility | Limited to basic operations (logging, perforation, pressure monitoring). | More versatile for complex tasks (stimulation, fishing, cementing). |

| Cost | Generally more cost-effective for simple operations. | Higher cost due to equipment complexity and specialized operations. |

| Real-Time Data | Provides precise measurements but often limited to diagnostic tasks. | Enables real-time fluid circulation and pressure monitoring during intervention. |

| Intervention Complexity | Best for shallow, less complex interventions. | Suitable for deep, high-pressure, and multi-functional interventions. |

Key Factors to Consider for Choosing between Wireline and Coiled Tubing for Well Intervention

1. Well Depth and Complexity of the Well

When considering coiled tubing and wireline for conducting well interventions for a particular well, it is vital to assess the well configuration and depth. Wireline methods are best suited for shallow and moderately deep wells that require interventions that are relatively easy, such as pressure monitoring, logging and perforating. Wireline also works best vertical and slightly deviated wells since it is quickly deployed and takes very short time to set up.

On the contrary, for deep wells that are highly deviated or have complex configurations, coiled tubing is the best option. Coiled tubing is very flexible and can easily and effectively navigate complex horizontal and curved sections in wellbores. This gives it an advantage when conducting interventions in very deep wells where wireline methods would be ineffective. Coiling tubing also has a broader range of operations that can be performed including fishing, stimulation, and acidizing which is very vital in deep and complex wells.

2. Pressure Handling Requirements

Another of these important considerations is the pressure environment where the intervention will be. Wireline is generally constrained in its ability to perform high-pressure operations. Wirelines are not built to withstand the high-pressure stages of operations such as hydraulic fracturing or stimulation of a well, though they can be employed in basic diagnostics and lighter interventions.

In contrast, coiled tubing is built to operate under these high-pressure conditions, which makes it the better alternative for operations that involve pressure control, acidizing, or fracturing. The uninterrupted flow of fluids in the coiled tubing system allows the system to effectively relieve pressure during stimulation or other high-pressure therapy, making it the preferred option for more demanding interventions in deeper and more complex well environments.

3. Type of Intervention Required

The type of well intervention required also greatly impacts the decision between wireline and coiled tubing. Less complex interventions that involve straightforward tool deployment are where Wireline shines. Some of the most common use cases include well logging, pressure monitoring, perforation, and wellbore cleaning. Its speed advantage, when it comes to deploying tool such as gauges and sensor, also makes it a more economical and effective option for simple interventions.

Despite the wide variety of available technologies, coiled tubing is more adaptable and can streamline even more operations. It is the technology of choice for operations involving the circulation of fluids, such as the stimulation of wells, acid injection, and cementing. It is also vital for fishing operations involving the recovery of lost or stuck equipment as well as for large-scale wellbore cleaning. The ability to continuously circulate fluid remains the most complex and valuable feature of coiled tubing.

4. Cost Considerations

Cost is always an important factor for any of the available options on the interventions. Wireline has lower operational costs than coiled tubing, so it is the more economical choice for interventions in shallow or simple wells. The equipment is also smaller and lighter, and it takes less resources to operate.

In contrast to the previous explained methods, coiled tubing is the most costly. The setups are bulkier, more complicated, and demand more specialized personnel and supporting surface equipement as they are more costly. The requirements centered around greatly powerful surface pumps and the continuous circulation of fluids alongside the powerful down hole tools greatly increase the costs of coiled tubing interventions. Yet, the increased costs are justifiable as coiled tubing has greater depth and has more versatility in more complex situations. This just be the ends in high pressured situations.

5. Setup Time and Operational Efficiency

In overall quickness to perform a well intervention, desired technology to be employed is often dictated. Due to less bulky equipement and less complex surface setups, wireline interventions are, in most cases, faster to deploy. This makes it a preferred alternative in situations needing quick interventions. Logging, measuring and monitoring well pressures or cleaning well bores are some of the tasks that rarely allow for lengthy downtime and can benefit greatly from this technology.

Coiled tubing needs more elaborate configurations than other kinds of tubing because of the need to position larger rigs and pumping systems to control the circulation of fluids. Larger setups undoubtedly take longer to configure, but the overall operational efficiency of coiled tubing is more than other kinds with respect to complex and longer operational quagmires. Tool circulation and simultaneous deployment, akin to a multitasking mechanism, gives coiled tubing tubing more operational efficiency in the case of complex quagmires involving deep, high-pressure wells with multi-stage operations.

6. Tool Deployment and Versatility

The variety of the intervention method is also a function of the kinds of tools required to be deployed. The use of wireline in such interventions is valuable in the deployment of small, less complex tools that include pressure sensors, measuring gauges, and perforating guns. Such a method is also advantageous in circumstances where the circulation of fluids is not necessary and pressure control is not significant in the operations.

Coiled tubing has a larger operational scope than wireline because of the greater variety of tools that can be deployed and the more complex tasks that can be handled. The deployment of larger and more complex tools is also within its capability in range of operations inclusive of stimulation, cementing, and fishing. The distinct advantage of coiled tubing in the circulation of fluids as tool deployment is in progress is necessary in complex and high-pressure interventions.

7. Risks of Failure and Reliability

Each has their own risk and chances of failures, of which some are greater for coiled tubing, but these risks are still present for wireline too. With wireline, breakage of the cable on the system, or jamming of parts of the system can occur. For coiled tubing, wear, kinking, and fatigue (especially of the system’s tubing which is the coiled portion) can occur. Regardless of these facts, in more complicated wells the increased risks of failures is overshadowed by coiled tubing’s ability of constantly circulating fluids and reliably deploying a variety of downhole tools.

Wireline has a more straightforward system of operations and is therefore, more reliable and has a lower risk of failure. It is the better option for shallow well interventions and for rudimentary diagnostic operations. However, when the operations involves more complicated conditions of the wellbore or high pressure of the system, wireline has its own fair share of risks making coiled tubing the more reliable option.

Summary

- The better option for shallow and less complex wells is wireline as it is more cost effective, quicker, and efficient for basic wellbore cleaning, perforating, and logging.

- For deep, more complex wells, or high-pressure wells, coiled tubing is the better choice, particularly for operations requiring high-pressure handling, acidizing, stimulation, or fishing. It is also the better choice for complex well geometries.

How Simulation Technologies are Used for Optimizing the Performance of Wireline and Coiled Tubing for Well Intervention

This chart displays how simulation technologies are applied to both wireline and coiled tubing operations, optimizing performance by modeling various physical, mechanical, and operational factors. Well intervention simulations are essential for improving safety and minimizing costs.

| Aspect | Wireline | Coiled Tubing |

| Wellbore Modeling | Simulations help predict the behavior of wireline tools in various wellbore conditions (depth, pressure, angle). | Simulations model the movement and performance of coiled tubing in deep, deviated, or high-pressure wells. |

| Tool Deployment Simulation | Simulation technologies optimize the deployment of wireline tools for tasks like logging, perforation, and pressure monitoring, ensuring efficient tool handling. | Coiled tubing simulators optimize the deployment of larger, more complex tools for stimulation, cementing, or fishing operations, ensuring proper fluid circulation and tool positioning. |

| Pressure and Flow Modeling | Simulates the effects of pressure changes on wireline operations, especially for pressure monitoring or well testing. | Simulates fluid flow through coiled tubing, including circulation rates, pressure drop, and the effects of stimulation treatments like acidizing or fracturing. |

| Mechanical Performance | Simulation helps predict the wireline’s mechanical strength, minimizing the risk of breakage or jamming during tool deployment. | Simulates the mechanical behavior of coiled tubing, including the risk of coil fatigue, kinking, or damage due to high pressure, depth, and bending. |

| Risk Assessment | Wireline simulations assess risks like tool failure, cable fatigue, and tool deployment failure, helping in optimizing operational safety. | Simulations assess the risk of equipment failure, wellbore interaction, and failure due to high-pressure operations, which is crucial for complex deep-well interventions. |

| Operational Efficiency | Simulations optimize wireline deployment speed, reducing setup time and improving overall operational efficiency. | Simulates the impact of continuous fluid circulation, reducing downtime and improving operational efficiency during multi-task interventions like stimulation and cementing. |

| Cost Optimization | Simulations help reduce operational costs by predicting the most efficient wireline intervention methods, especially for simpler tasks. | Simulations help minimize costs by optimizing coiled tubing use in deep, complex, or high-pressure wells, allowing for more effective multi-task interventions without unnecessary equipment use. |

| Downhole Tool Interaction | Simulations predict the interaction of wireline tools with the wellbore environment (e.g., friction, fluid flow), ensuring optimal tool performance. | Coiled tubing simulations optimize the interaction of tools with the wellbore, ensuring proper tool placement and flow during simultaneous fluid injection or multi-stage operations. |

| Real-time Data Integration | Wireline simulations allow for integration with real-time data from sensors, optimizing interventions based on real-time downhole conditions. | Coiled tubing simulations integrate with real-time data from pressure and flow sensors, enabling dynamic adjustments during operations like fracturing or acidizing. |

Final Thoughts

Wireline and coiled tubing are invaluable instruments for contemporary well intervention. The choice between wireline and coiled tubing for well intervention hinges on several considerations, specifically on well depth, well pressure, type of intervention, cost considerations, etc. These drivers, to a great extent, assist operators in effective decision-making and ultimately achieving optimized and more efficient well intervention.